Long U pipe bending machine and operation method thereof

A technology of bending machine and bending mechanism, applied in heat exchange equipment and other directions, can solve the problems of high product defect rate, low degree of automation, large floor space, etc., and achieve the effects of compact structure, high degree of automation, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

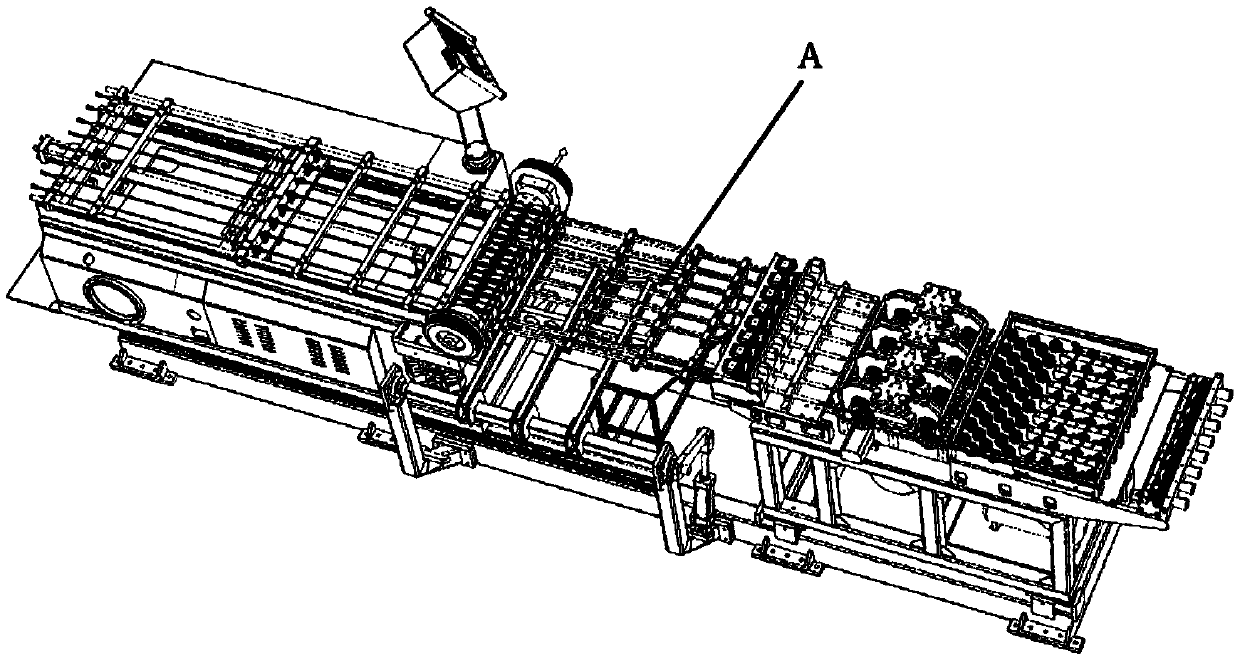

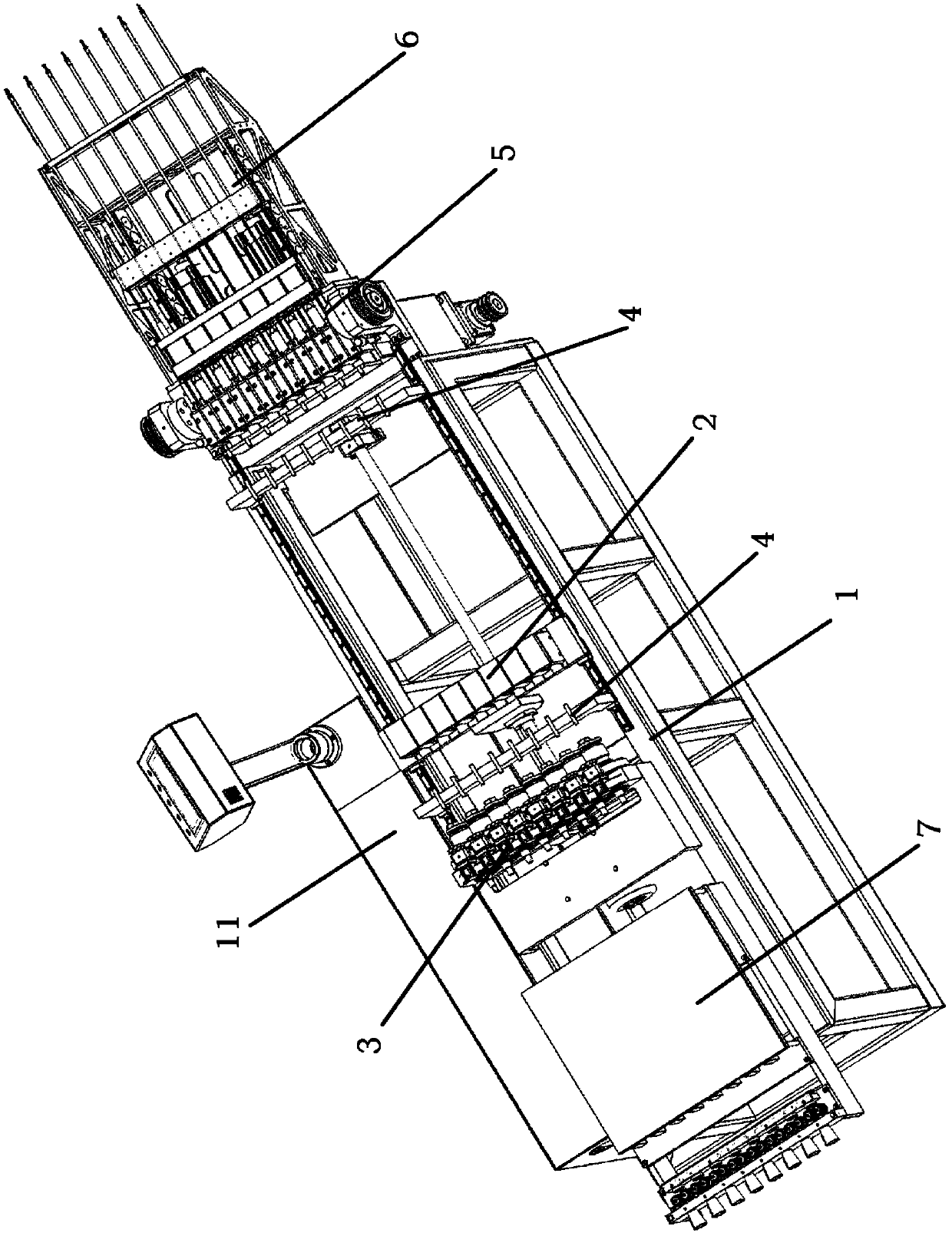

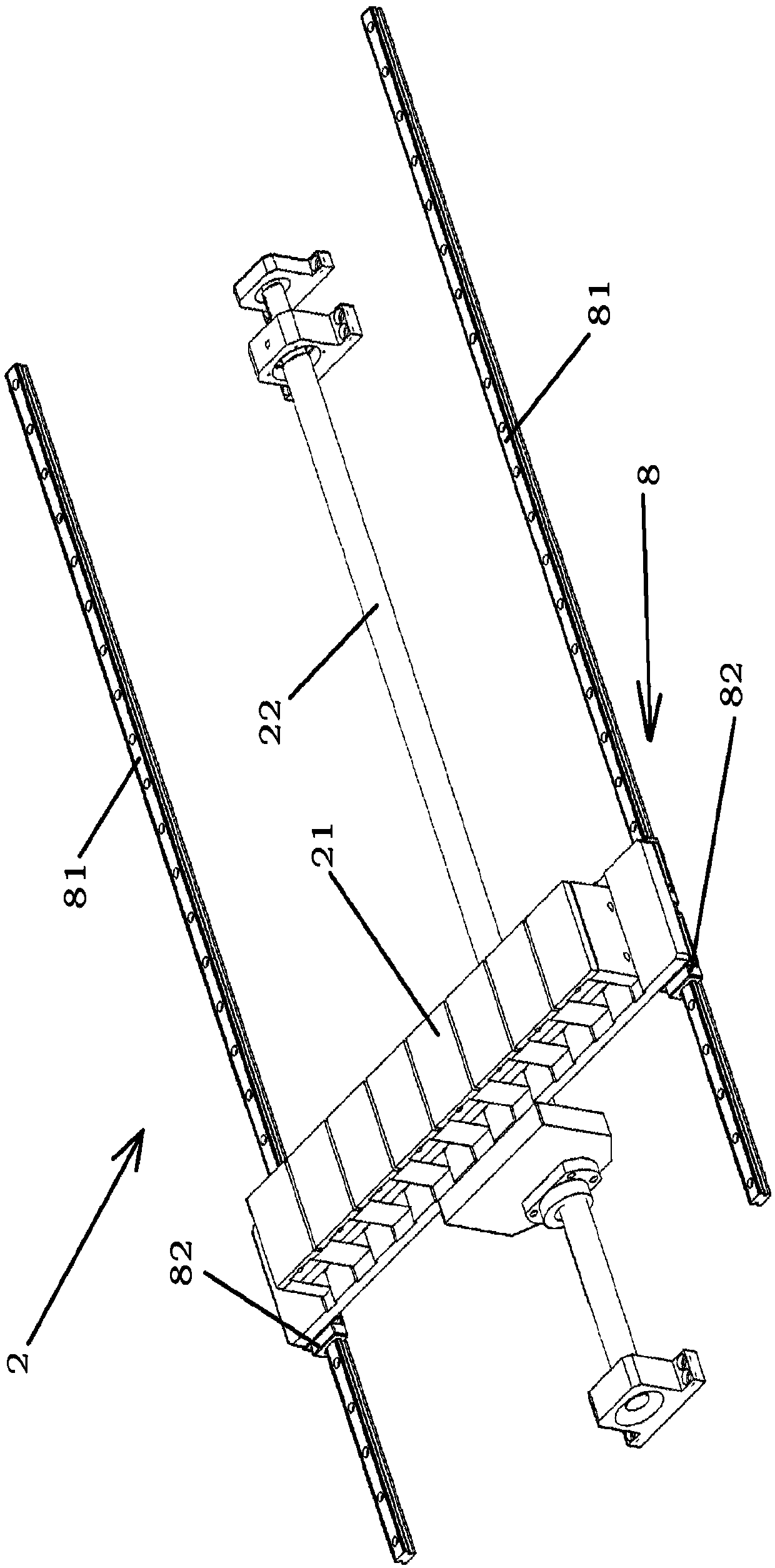

[0041] Figure 2 to Figure 9 A long U-tube bending machine according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a machine platform 1 provided with a control electric box 11 and a cutting mechanism 3 , a bending mechanism 5 and a clamping and feeding mechanism 2 arranged on the machine platform 1 .

[0042] Wherein, the cutting mechanism 3 is arranged in the middle of the machine 1, and is used for cutting the pipe according to a predetermined length.

[0043] The cutting mechanism 3 is fixedly connected with the machine table 1, and mainly includes a set of eccentric outer cutters 31 and a motor 32 for driving the eccentric outer cutters 31 to rotate.

[0044] The pipe passes through the inside of the eccentric outer cutter 31 .

[0045] The rotation axis of the eccentric outer cutter 31 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com