Online weld joint rectification method for arc welding robot based on structured light visual sensing

A visual sensor and visual sensing technology, applied in manipulators, welding accessories, welding equipment, etc., can solve problems such as unsatisfactory welding quality and welding efficiency, large dimensional deviation, and poor positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

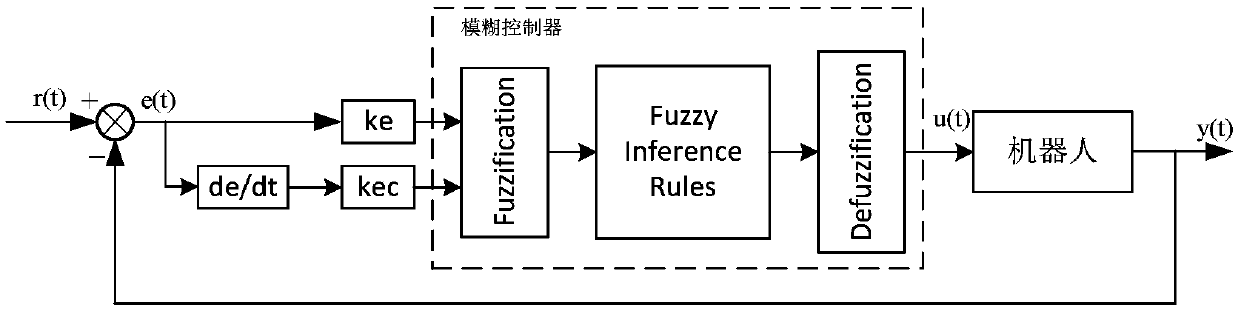

[0066] The invention proposes an online deviation correction method for arc welding robot welds based on structured light vision sensing, which is mainly oriented to the flexible welding production of arc welding robots, so that arc welding robots can cope with inconsistent workpiece sizes and inconsistent positioning During the deviation correction process, with the aid of the visual sensor, the position of the end of the welding torch is corrected and the continuity and stability of the welding process is ensured.

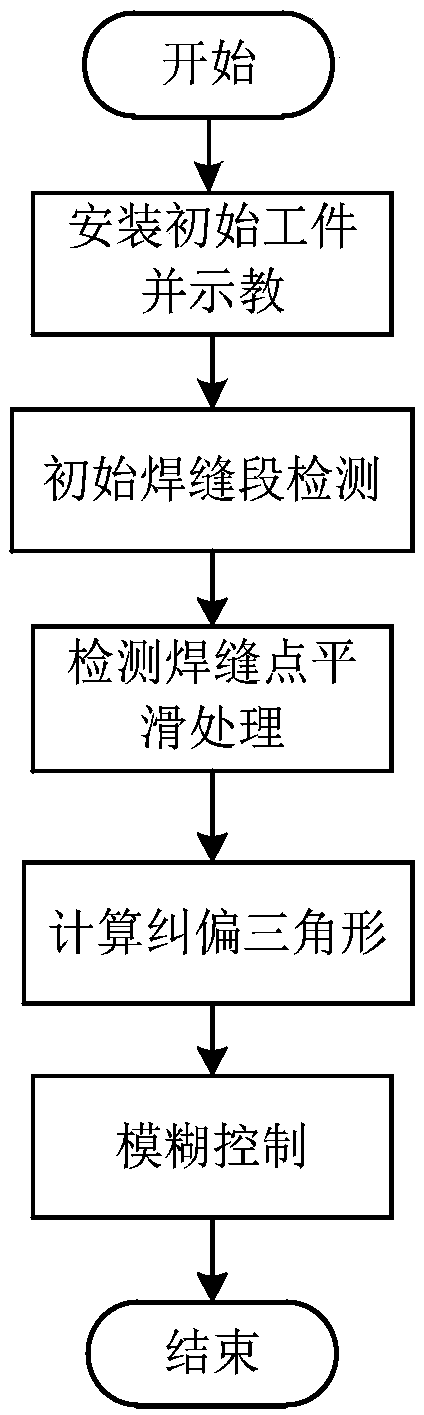

[0067] Such as figure 1 As shown, an arc welding robot weld seam online correction method based on structured light vision sensing is characterized in that it includes the steps:

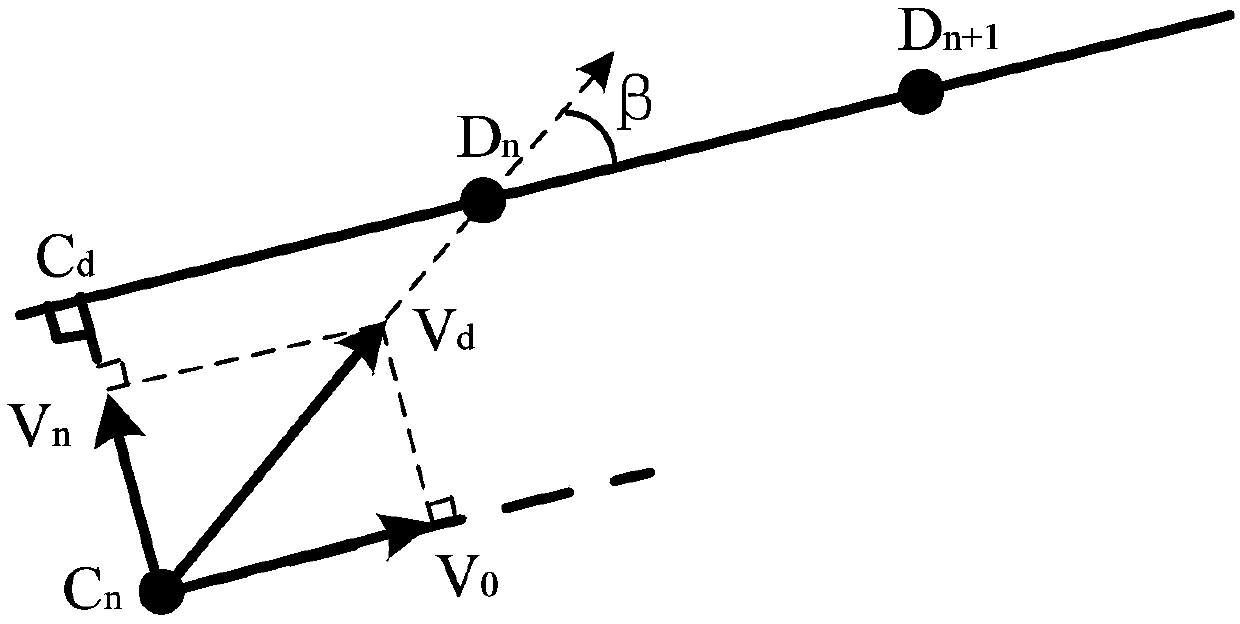

[0068] Step 1. Teach the first workpiece to obtain the posture of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap