Method for calculating energy consumption of numerical control machine tool in cutting stage

A CNC machine tool and cutting specific energy technology, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problem of not considering the impact of tool wear on the energy consumption of CNC machine tools, and not considering the no-load of the CNC machine tool spindle Energy consumption and other issues, to achieve the effect of high calculation accuracy and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

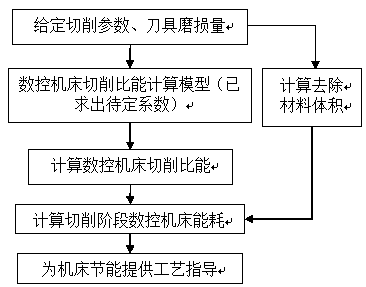

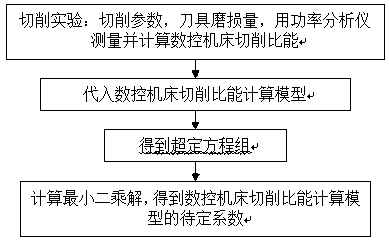

[0025] Combine below figure 1 figure 2 The present invention is further described in detail.

[0026] In step 1), according to the relationship between CNC machine tool cutting parameters and energy consumption, and considering the impact of tool wear on machine tool energy consumption, a calculation model of CNC machine tool cutting specific energy is established:

[0027] Sec=k 0 *(1+VB)+k 1 *n / MRR+k 2 / MRR (5)

[0028] Among them, Sec is the cutting specific energy of CNC machine tool; VB is the amount of tool wear; n is the spindle speed of CNC machine tool; MRR is the material removal rate; k 0 、k 1 and k 2 is the undetermined coefficient.

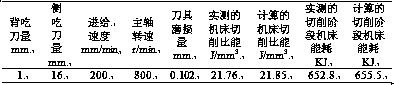

[0029] In step 2), measure and calculate the undetermined coefficients in the cutting specific energy calculation model of the CNC machine tool with the help of a power analyzer. After the tool material, workpiece material, and processing method are determined, the CNC cutting experiment is carried out:

[0030] For each cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com