Automatic die waterway cleaning mechanism

An automatic mold and cleaning mechanism technology, applied in the field of molds, can solve problems such as affecting the circulation of cooling water, losing cooling efficiency of molds, affecting product quality, etc., and achieve the effect of improving cooling effect, smooth and effective waterway operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

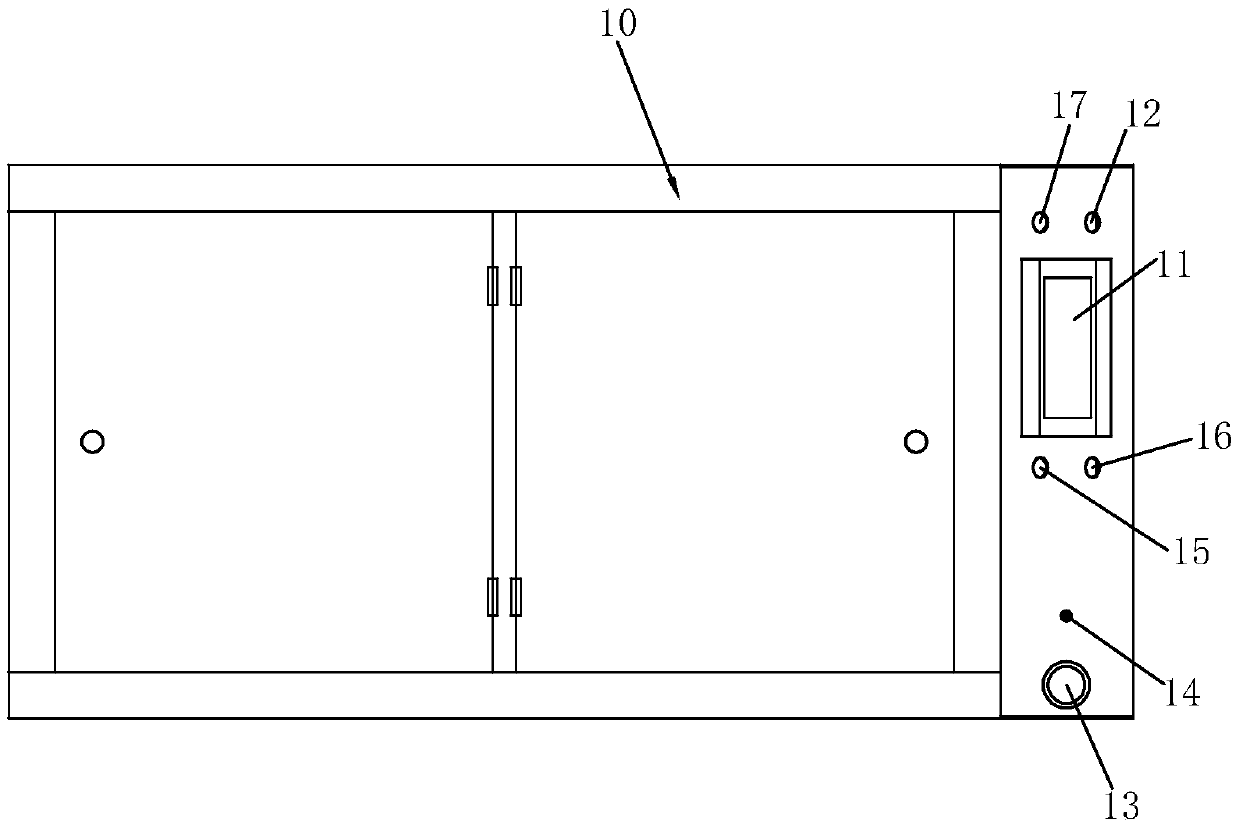

[0026] like figure 1 and figure 2 As shown, the automatic mold waterway cleaning mechanism of the present invention includes a control electric cabinet 10, on which an intelligent operation interface 11, a power switch 12, a barometer 13, an eddy current flow regulator 14, and a power indicator light 15 are arranged. And running indicator light 16 and buzzer 17. The intelligent operation interface 11 is used to control the operation of the whole equipment, the vortex washing flow regulator 14 is used to adjust the intake air quantity during quantitative compressed air vortex washing, and the buzzer 17 is used for alarm and warning after cleaning effect.

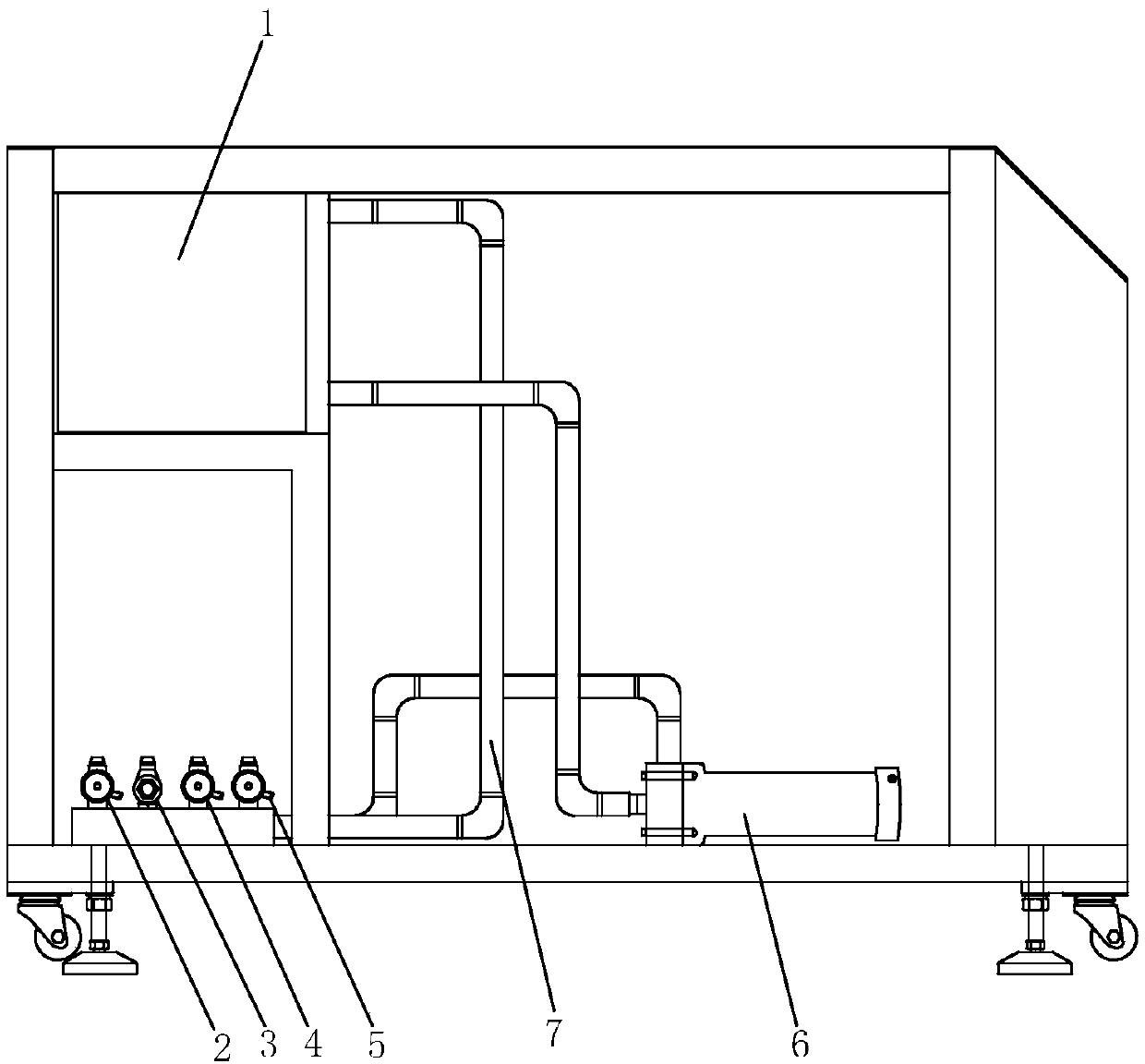

[0027] like figure 1 and figure 2 Shown, be provided with tank 1, solenoid valve 2, one-way valve 3, solenoid valve 4, solenoid valve 5, water pump 6 and cleaning machine inlet and outlet water pipe 7 in control electric cabinet 10. The inside of the water inlet and outlet pipe 7 of the washing machine is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com