Anti-collision type car charging pile

A technology for car charging and charging piles, which is applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of easy opening of the cover and reducing the anti-collision effect of the display interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

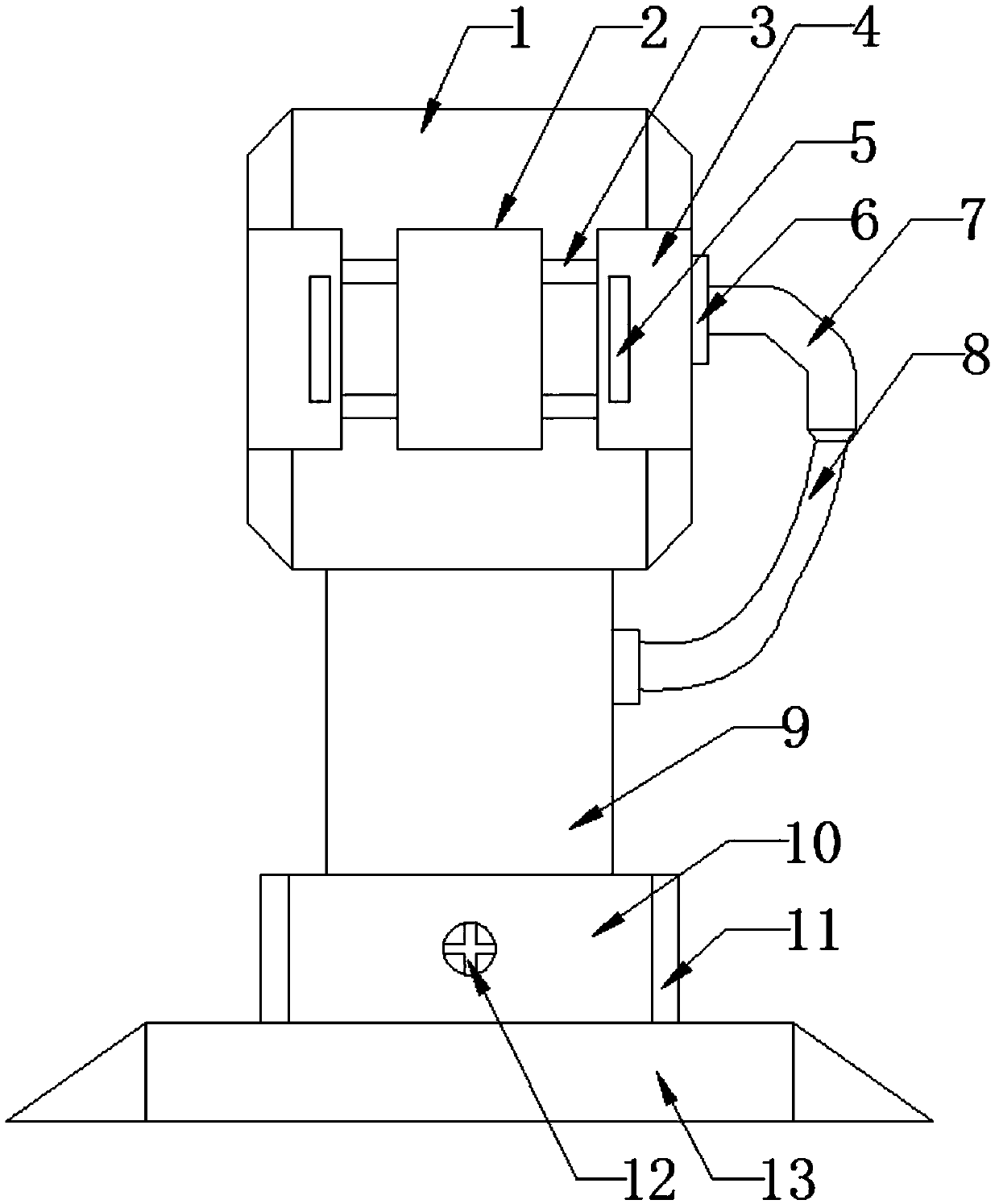

[0025] see Figure 1-4 , this embodiment provides an anti-collision vehicle charging pile, including a charging pile main body 1; a display interface 2 is provided on the outer surface of the charging pile main body 1, and sliding rails 3 are arranged on the left and right sides of the display interface 2 The left and right sides of the sliding track 3 are provided with a cover body 4, and the outer surface of the cover body 4 is fixed with a handle 5, two cover bodies 4 are provided, and the cover body 4 is symmetrically distributed on the outside of the display interface 2, The sum of the lengths of the cover 4 is greater than the length of the display interface 2, and the sum of the widths of the cover 4 is greater than the width of the display interface 2, ensuring that the cover 4 can completely cover the display interface 2, and the gap between the cover 4 and the sliding track 3 It is a sliding connection structure; the connection between the handle 5 and the cover 4 is...

Embodiment 2

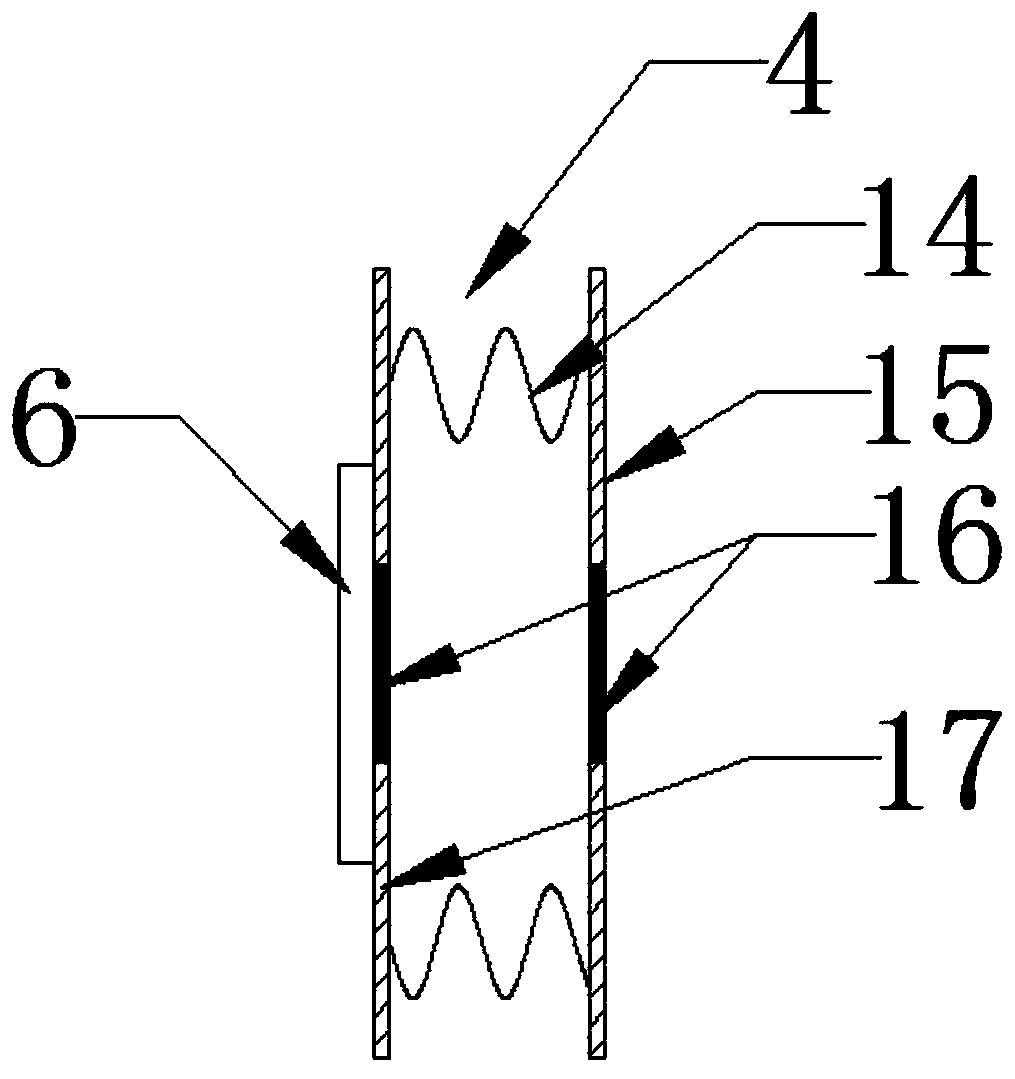

[0029] see image 3 , in this embodiment, the cover plate 17 and the middle part of the side of the rubber plate 15 are provided with a magnet 16, through the magnet 16, the two covers 4 can attract each other when sliding and closing, thereby fixing the two covers 4.

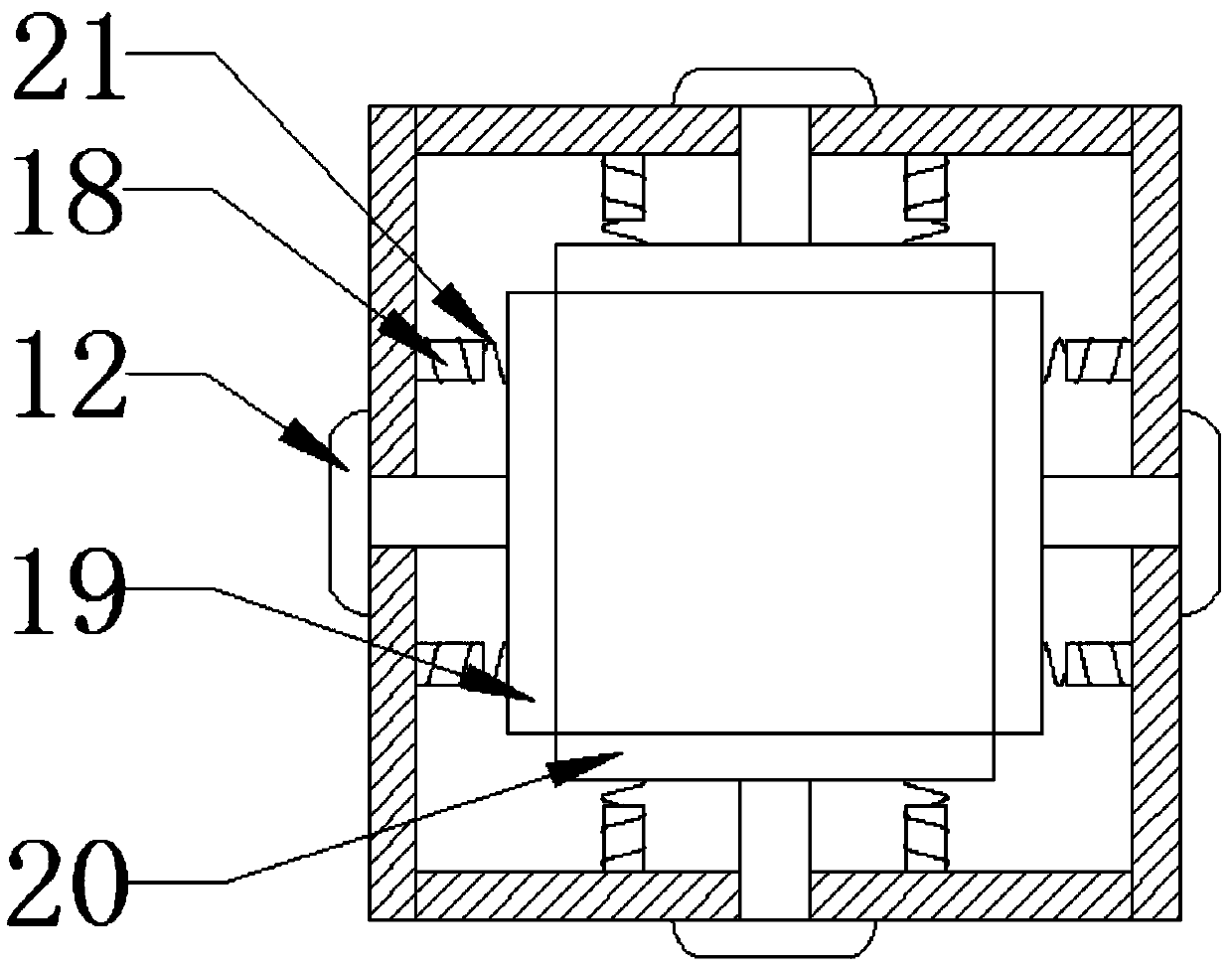

[0030]The working principle of the present invention is: by tightening the fastening bolt 12, the third fixed plate 19 and the fourth fixed plate 20 are clamped and fixed to the connecting strut 9, and the fixed connecting strut 9 is protected against collision; at the same time, the second spring 21 is used to It is supported between the first fixed plate 10 and the third fixed plate 19 to further counteract the impact force. In addition, when the fixed connection pillar 9 is subjected to a huge impact, in order to prevent the failure of both the third fixed plate 19 and the second spring 21, it is located at The protective rod 18 inside the second spring 21 can play a final protective role; the display interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com