Automatic collection and transfer device for aluminum ash particles

A technology of automatic collection and transfer device, applied in packaging and other directions, can solve the problems of high labor intensity, inability to quantitatively pack, labor-intensive and other problems, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

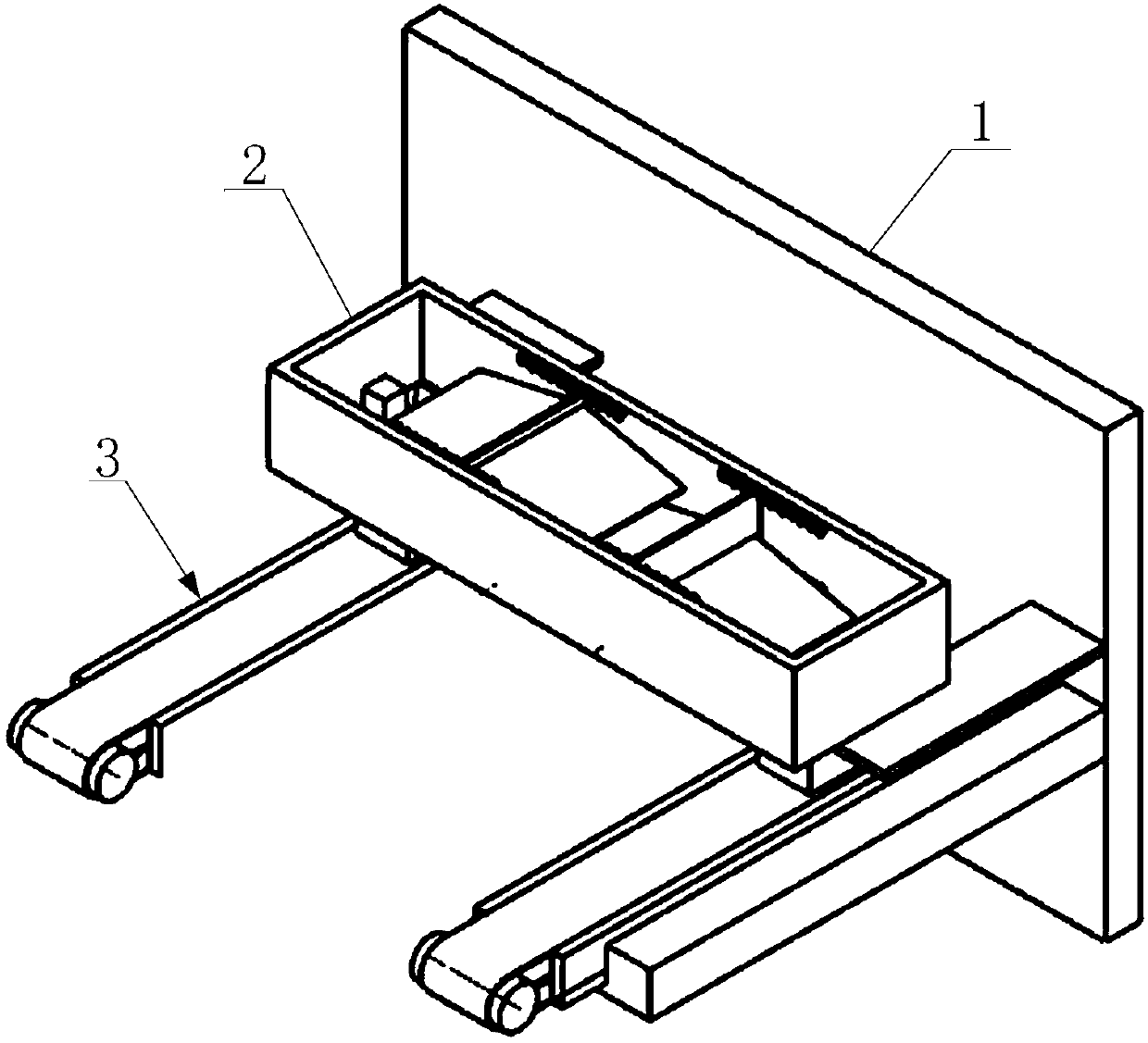

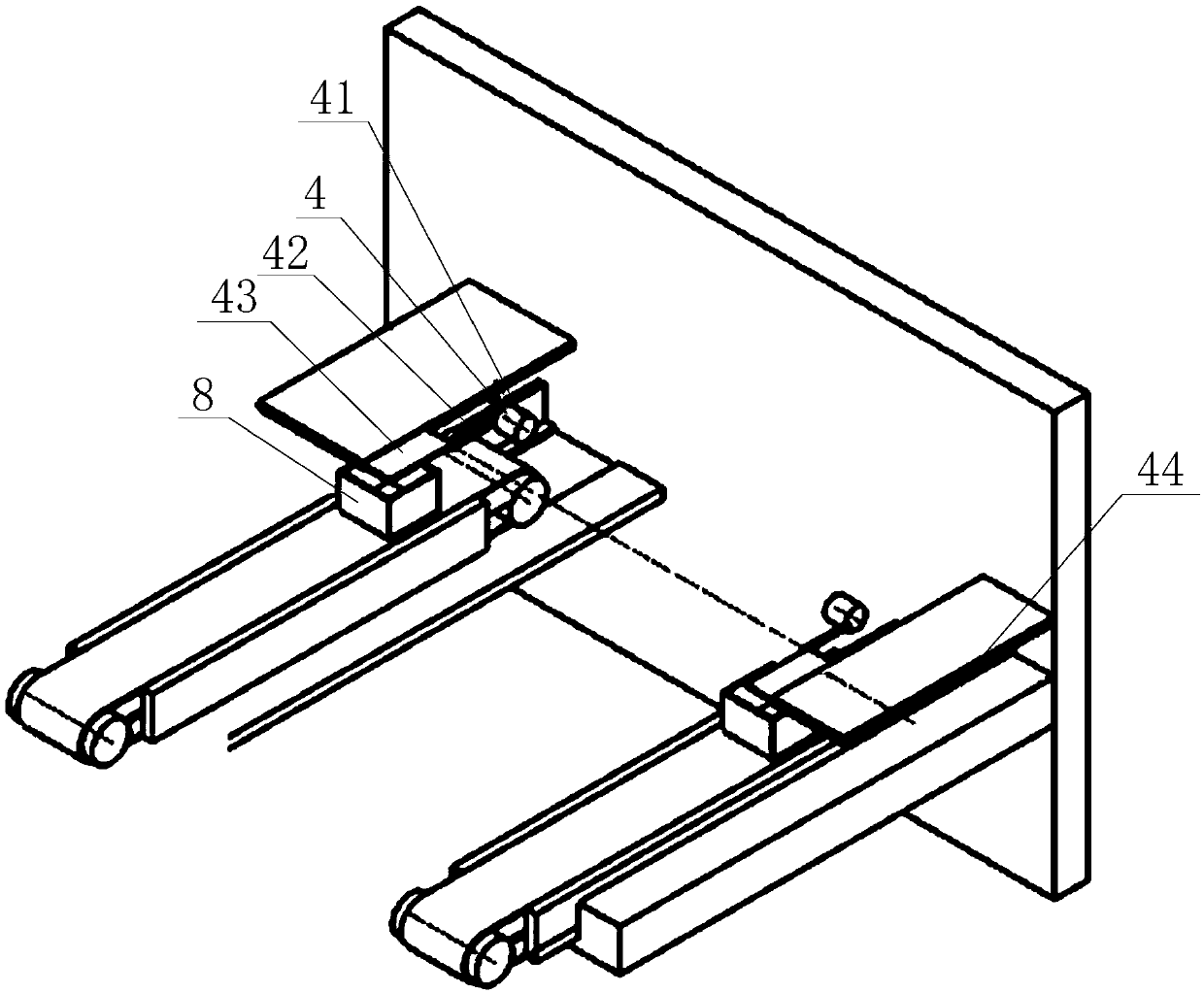

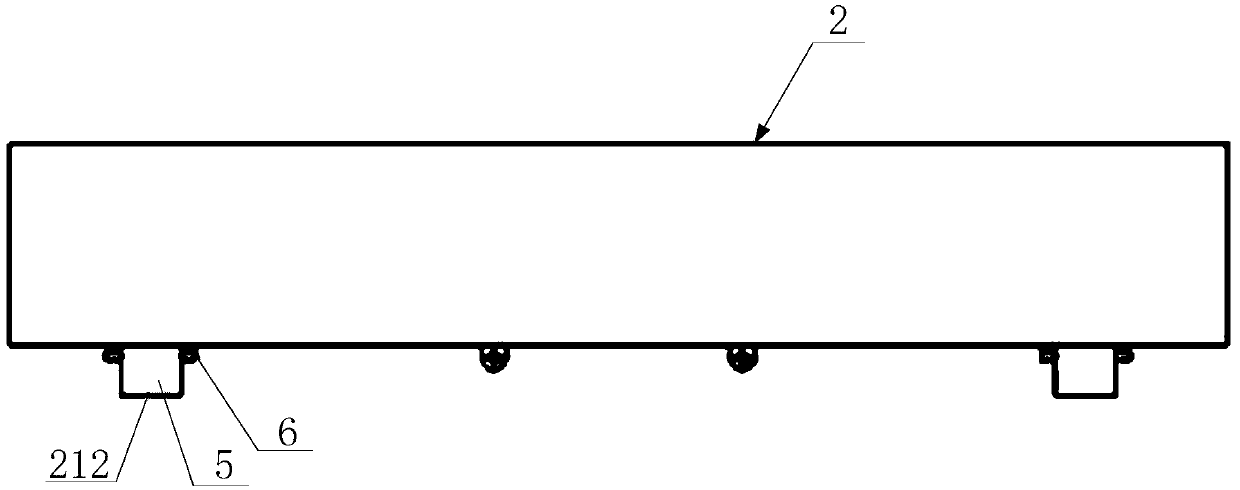

[0021] According to the attached Figure 1 to Figure 5 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0022] see Figure 1 to Figure 5 , an automatic collection and transfer device for aluminum ash particles according to an embodiment of the present invention, comprising a frame 1, a trough 2, two transmission mechanisms 3 and two blanking control mechanisms 4, in this embodiment, the transmission mechanism 3 adopts a conveyor belt; The trough 2 and the blanking control mechanism 4 are fixed on the frame 1; the trough 2 includes a trough body 21 and two guides 22, and two lower hoppers 211 are formed inside the trough body 21, the top of the trough body 21 is open and the top of the trough body 21 The bottom forms a discharge port 212 corresponding to and connected to the position of the discharge hopper 211; the discharge control mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com