Intelligent quantitative injection system and intelligent quantitative injection method thereof

A quantitative filling and intelligent technology, applied in the field of filling systems, can solve the problems of troublesome filling machines, inability to automatically determine, and low efficiency, so as to improve filling efficiency, save filling costs, and improve filling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

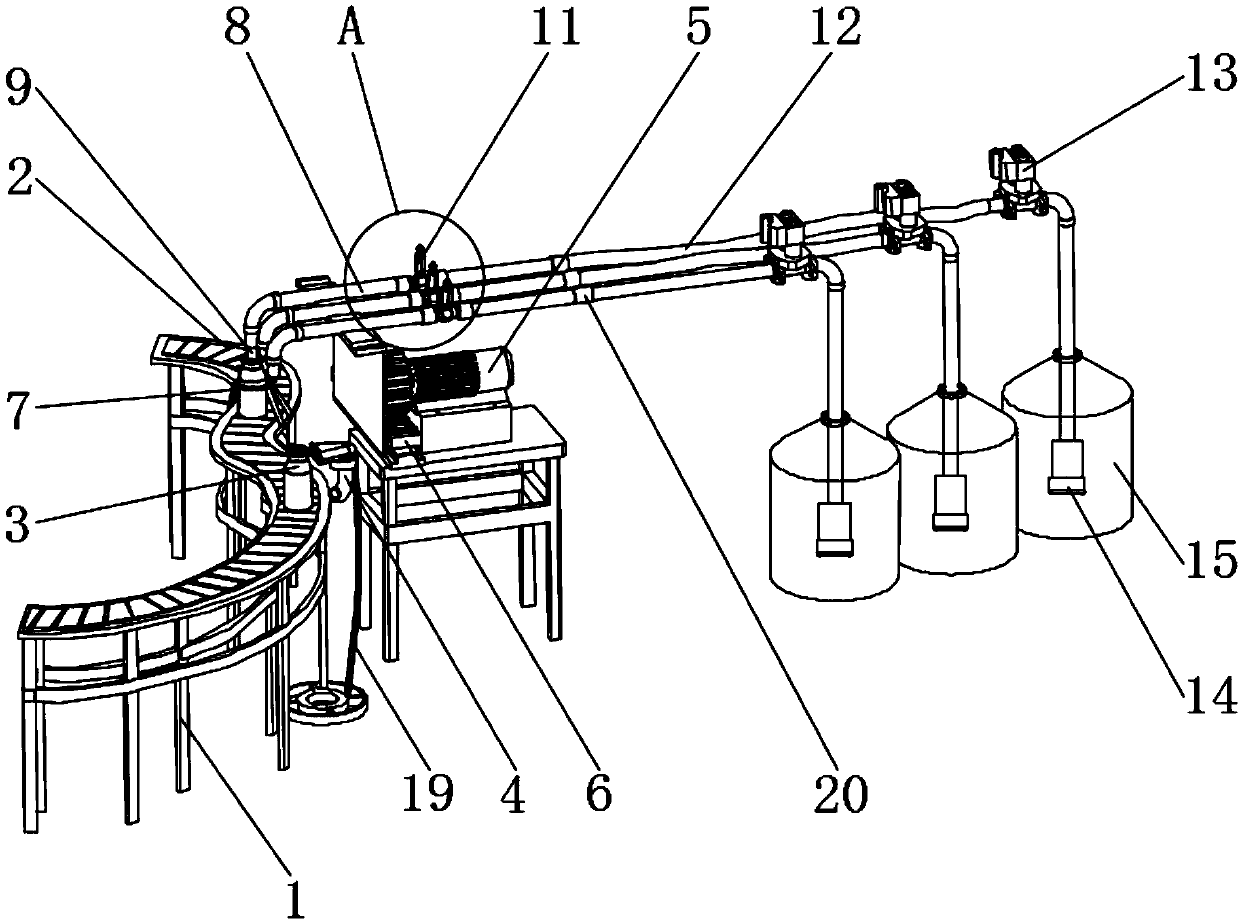

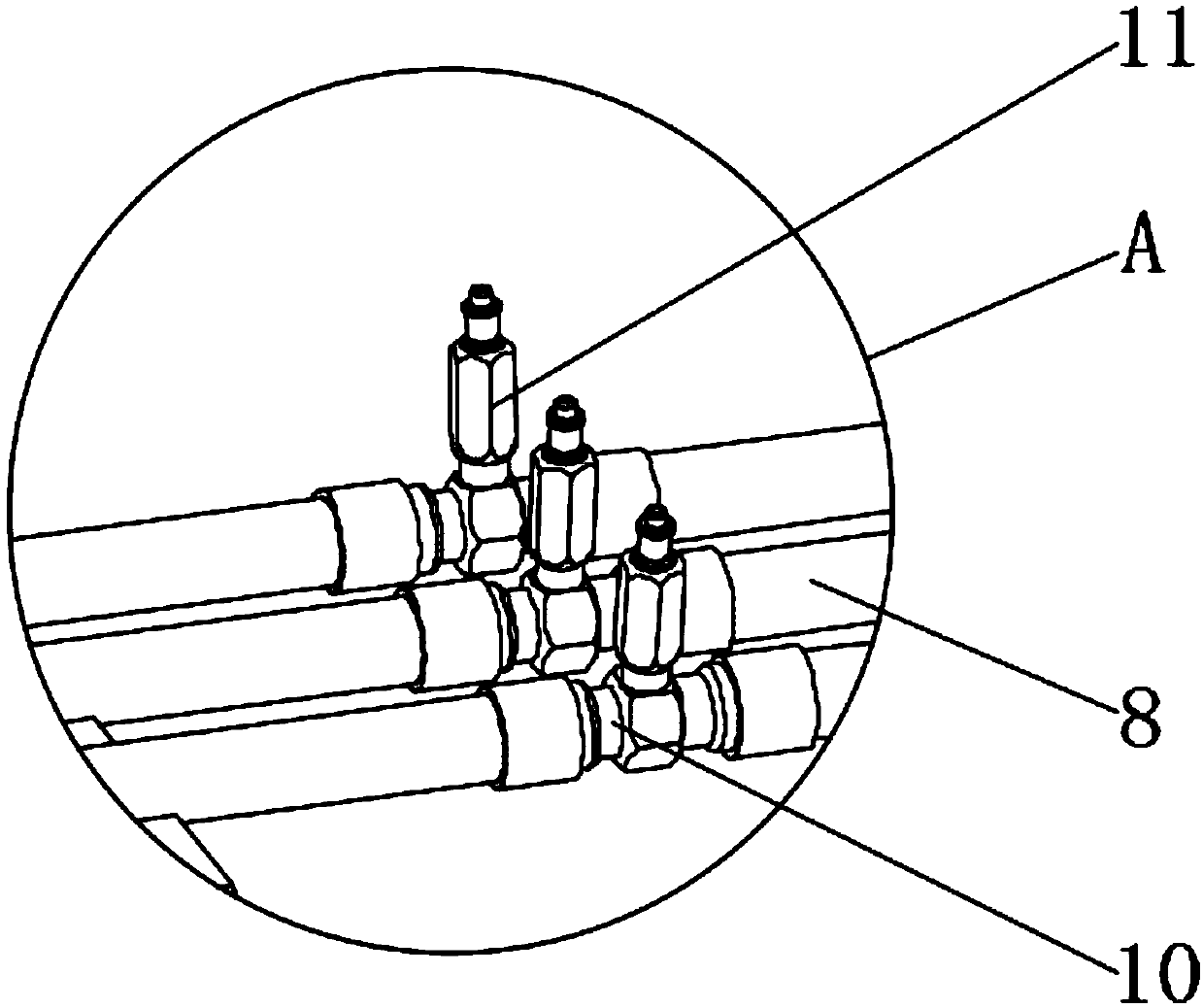

[0062] see Figure 1-3 , the intelligent quantitative filling system of this embodiment includes a transmission device, a code scanning gun 4, a controller, a transposition mechanism, a clamping device 7, a plurality of liquid storage tanks 15, and pipelines corresponding to a plurality of liquid storage tanks 15 mechanism.

[0063] The conveying device includes a supporting platform 1 and a conveying belt 2 . The conveyor belt 2 arranged in a wave shape is installed on the support platform 1 and transmits the container 3 to be filled on the conveyor belt 2. The clamping device 7 is installed on the support platform 1 and clamps the container 3 when receiving the container 3. In this implementation In an example, the clamping device 7 can work by manual fixing. Wherein, the distances between the containers 3 are all the same, so that it is convenient to control the delivery time of the delivery device. The clamping device 7 can be arranged outside the conveyor belt 2, and t...

Embodiment 2

[0091] see Figure 7 The intelligent quantitative filling system of this embodiment is similar to the intelligent quantitative filling system of Embodiment 1, and the only difference is that the intelligent quantitative filling system of this embodiment also includes a code scanning positioning mechanism. The code scanning and positioning mechanism includes a turntable 21 and a driving motor. The turntable 21 is set at the code scanning position and separates the conveyor belt 2 into two parts that operate independently; when the controller controls the front part of the conveyor belt 2 to transfer the container 3 to the turntable 21, the controller controls the conveyor belt 2 to stop, and Control the drive motor to drive the turntable 21 to rotate, and the turntable 21 drives the container 3 to rotate, so that the scanning gun 4 scans the container 3 in a 360-degree circular code, and starts the conveyor belt 2 to transfer the container 3 after obtaining the scanning informati...

Embodiment 3

[0094] see Figure 8-10 The intelligent quantitative filling system of this embodiment is similar to the intelligent quantitative filling system of Embodiment 1, and the only difference is that the intelligent quantitative filling system of this embodiment also includes a code scanning positioning mechanism. The code scanning and positioning mechanism here is different from the code scanning and positioning mechanism in Embodiment 2. The code scanning positioning mechanism of the present embodiment includes an air pump, a telescoping rod 22, a rotating motor 23, and a protective cover 24; The telescopic rod 22 is driven and expanded by the air pump; when the controller controls the conveyor belt 2 to transport the container 3 to the code scanning position, the controller also controls the air pump to drive the telescopic rod 22 so that the telescopic end of the telescopic rod 22 is downward Extend to drive the protective cover 24 to surround the container 3, and the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com