Measuring device and method for minimum technical output force of extraction condensing-type steamer generator set

A technology of steam turbine generator set and technical contribution, which is applied in the direction of steam engine devices, safety devices, engine components, etc., which can solve the problems of poor accuracy and long time consumption, and achieve the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

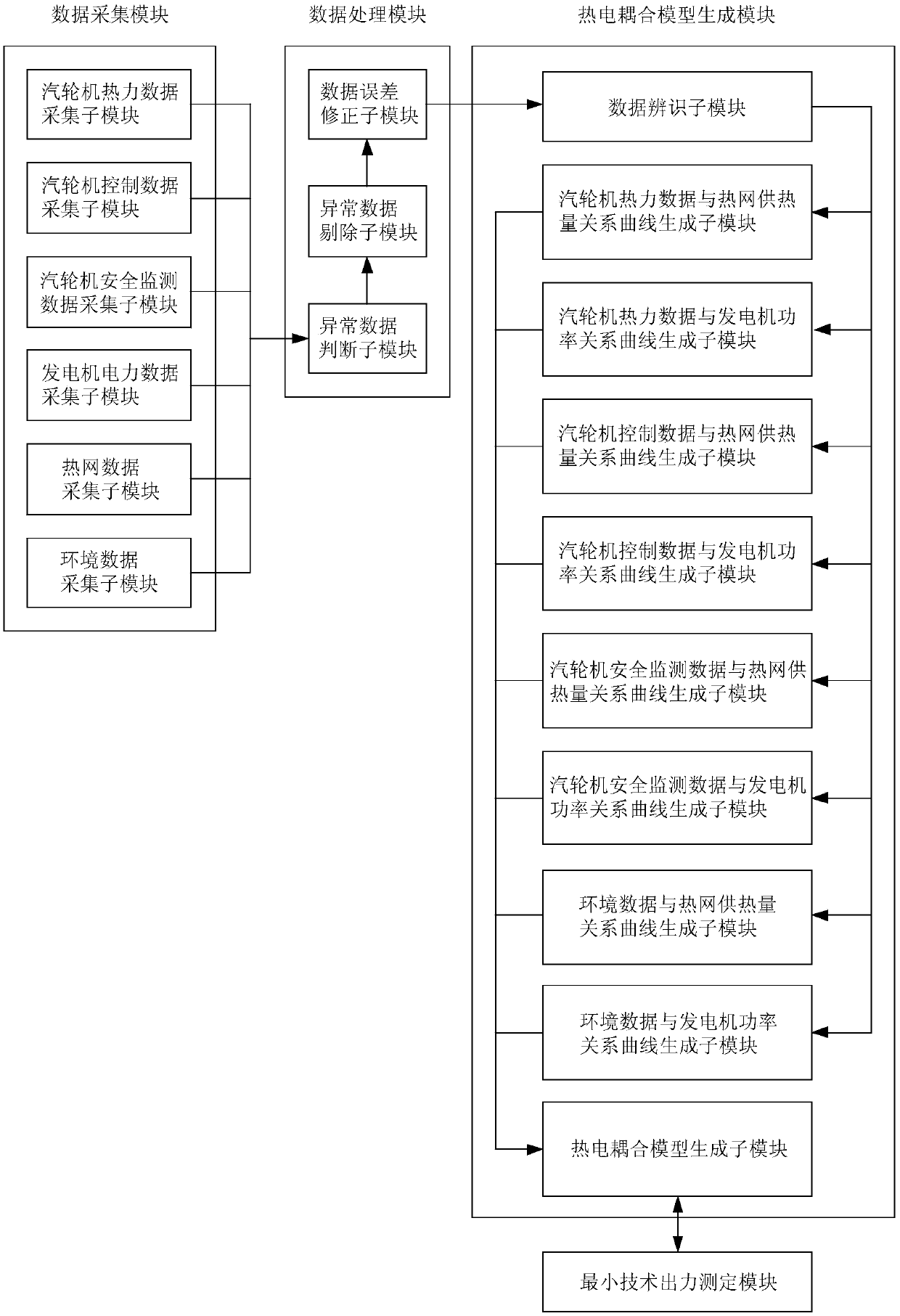

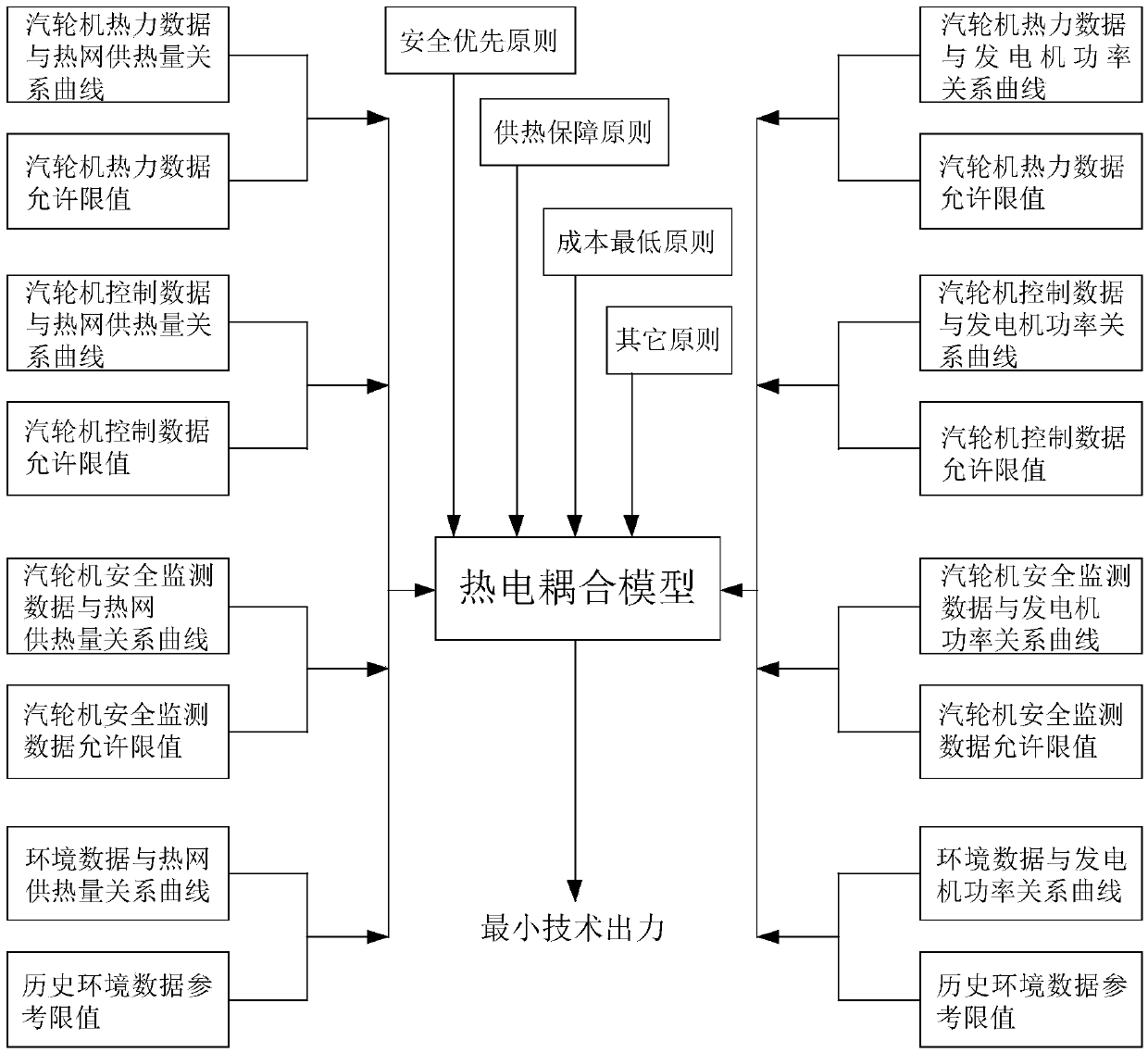

[0072] Embodiment one: combine below figure 1 with figure 2 This embodiment will be described in detail.

[0073] The minimum technical output measuring device of the extraction condensing type turbogenerator set described in this embodiment, the extraction condensing type turbogenerator set includes an extraction condensing type steam turbine and a generator, both of which realize cogeneration of electricity and heat together, the minimum technical output measurement Devices include:

[0074] The data acquisition module is used to collect the thermal data of the steam turbine, the control data of the steam turbine, the safety monitoring data of the steam turbine, the power data of the generator, the heating network data and the environmental data;

[0075] The data processing module is used to judge whether each data group collected by the data acquisition module contains abnormal data. Error correction is performed on the data set;

[0076] The thermoelectric coupling m...

Embodiment 2

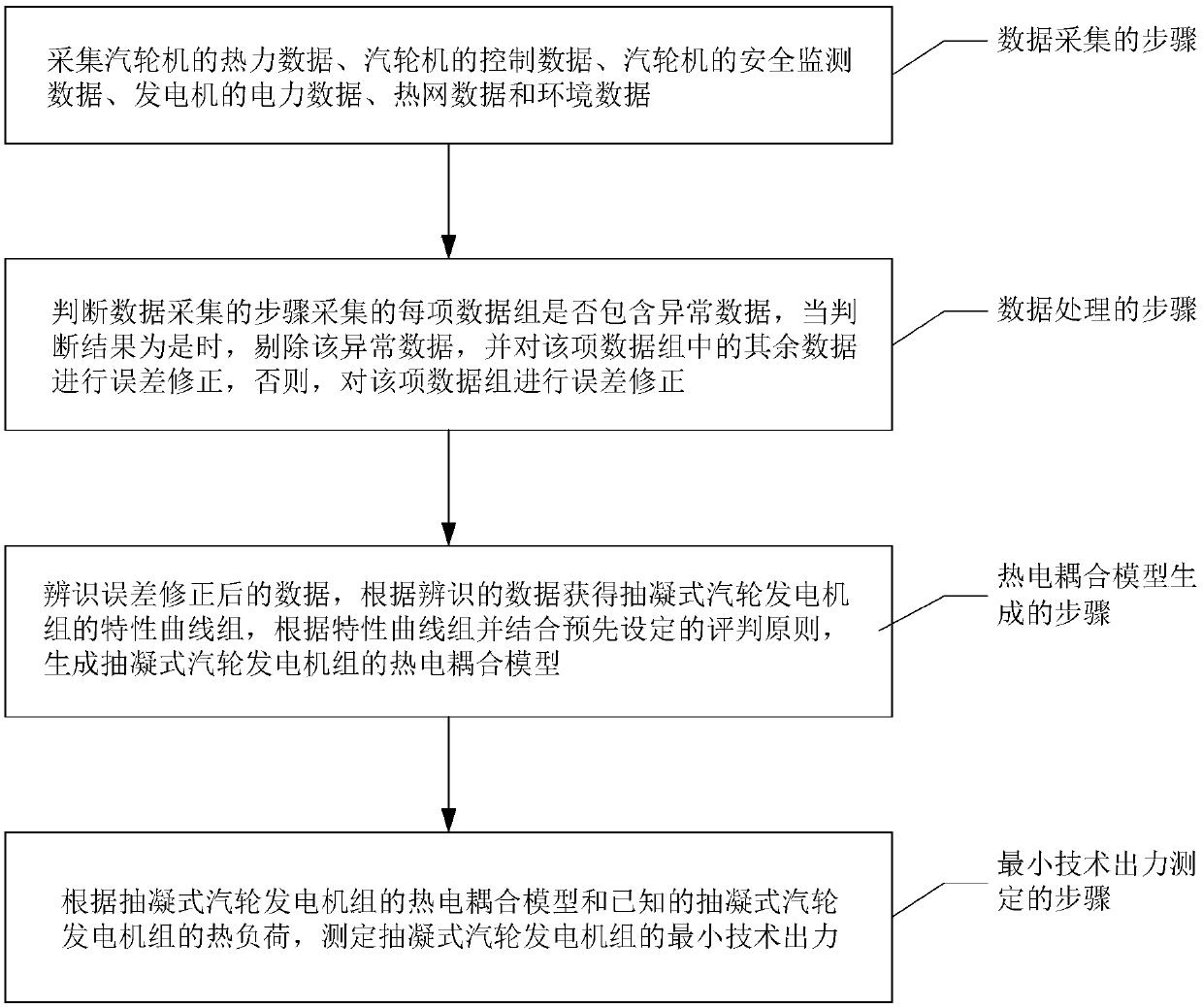

[0126] Embodiment two: combine below image 3 This embodiment will be described in detail.

[0127] The method for measuring the minimum technical output of the extractive condensing turbo-generator set described in this embodiment, the extractive condensing turbo-generator set includes an extractive condensing steam turbine and a generator, both of which jointly realize cogeneration of electricity and heat, and the minimum technical output is measured Methods include:

[0128] The step of data collection is to collect the thermal data of the steam turbine, the control data of the steam turbine, the safety monitoring data of the steam turbine, the electric power data of the generator, the heating network data and the environmental data;

[0129] The step of data processing is to judge whether each data group collected in the step of data collection contains abnormal data. Error correction is performed on the data set;

[0130] The steps of thermoelectric coupling model gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com