Military heat dissipation device with auxiliary heat dissipation function

A technology to assist heat dissipation and radiator, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., to prevent offset and crush injury, improve stability, and improve heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

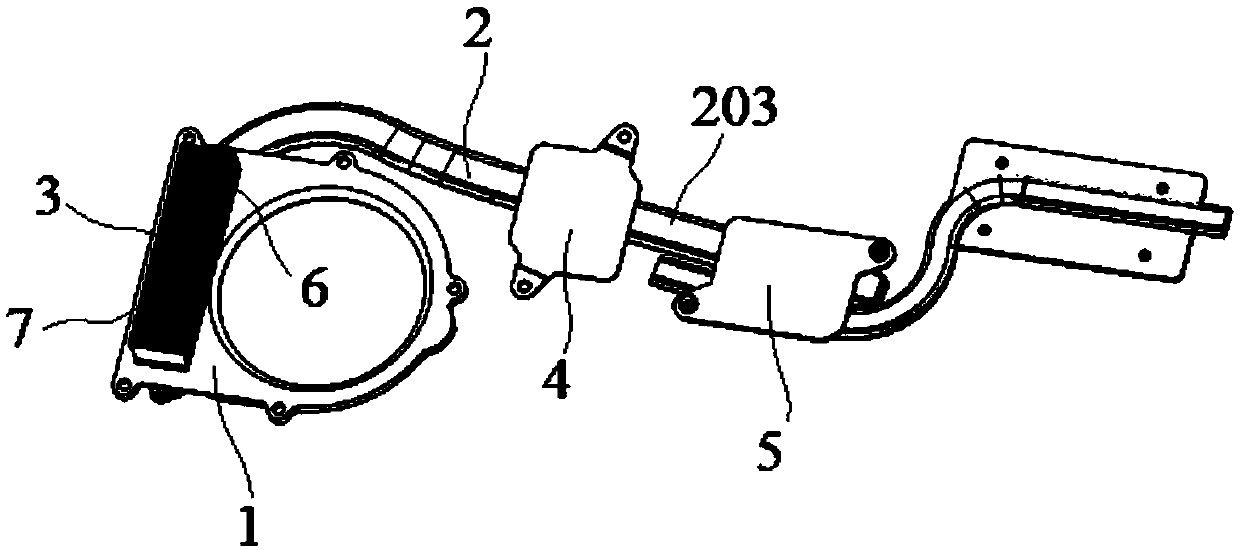

[0025] Embodiment 1: A military radiator with auxiliary heat dissipation function, including a mounting seat 1 for installing a fan, a main heat pipe 2, a heat dissipation fin group 3, a first heat absorbing fin 4 and a second heat absorbing fin 5, so The heat dissipation fin group 3 is arranged on one side surface of the installation base 1, and the other side surface of the installation base 1 is connected to the heat dissipation end 201 of the main heat pipe 2. The first heat absorption fin 4 and the second heat absorption fin 5 They are respectively connected to the heat-absorbing end 202 of the main heat pipe 2, and the second heat-absorbing sheet 5 is located on the side of the first heat-absorbing sheet 4 opposite to the mounting seat 1;

[0026] The heat dissipation fin group 3 is formed by sequentially buckling fins arranged in parallel, thereby forming several air ducts arranged in parallel. One side of the air duct is the air inlet 6, and the other side is the air ou...

Embodiment 2

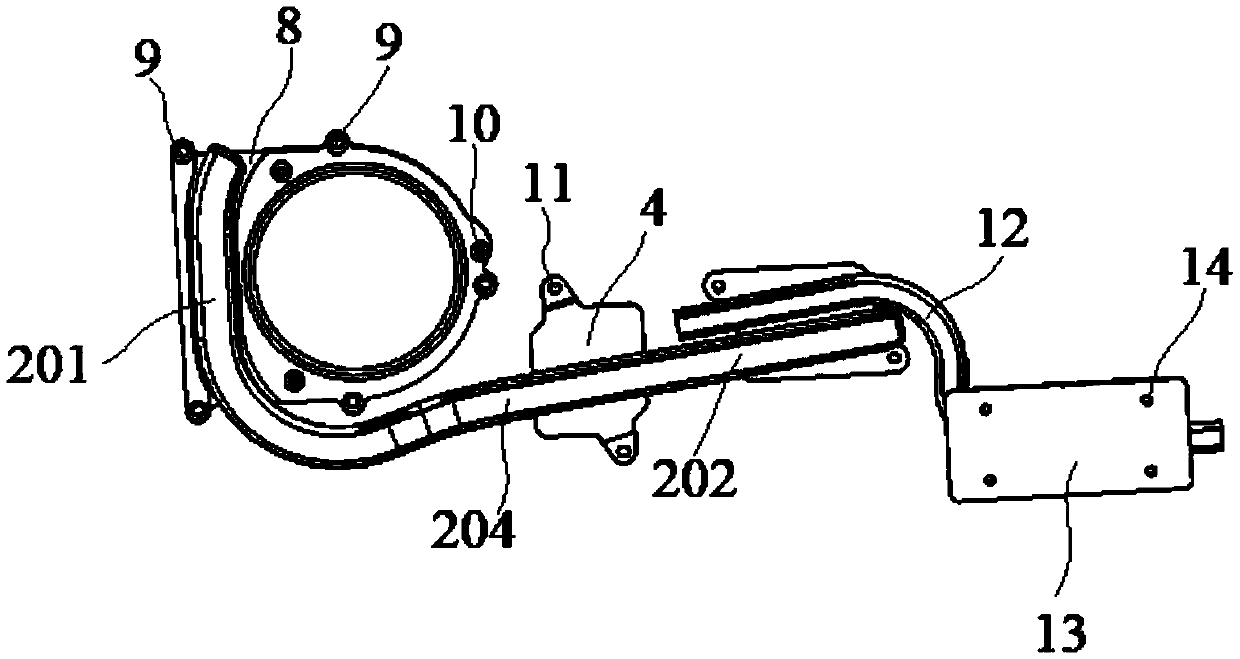

[0030] Embodiment 2: A military radiator with auxiliary heat dissipation function, including a mounting base 1 for installing a fan, a main heat pipe 2, a heat dissipation fin group 3, a first heat absorbing fin 4 and a second heat absorbing fin 5, the The heat dissipation fin group 3 is arranged on one side surface of the installation base 1, and the other side surface of the installation base 1 is connected to the heat dissipation end 201 of the main heat pipe 2. The first heat absorption fin 4 and the second heat absorption fin 5 They are respectively connected to the heat-absorbing end 202 of the main heat pipe 2, and the second heat-absorbing sheet 5 is located on the side of the first heat-absorbing sheet 4 opposite to the mounting seat 1;

[0031] The heat dissipation fin group 3 is formed by sequentially buckling fins arranged in parallel, thereby forming several air ducts arranged in parallel. One side of the air duct is the air inlet 6, and the other side is the air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com