Circuit board nut reinforcement device

A reinforcement device and circuit board technology, applied to nuts, printed circuits, printed circuits, etc., can solve problems such as unusable, circuit board sliding, etc., to achieve the effect of increasing firmness, increasing reliability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

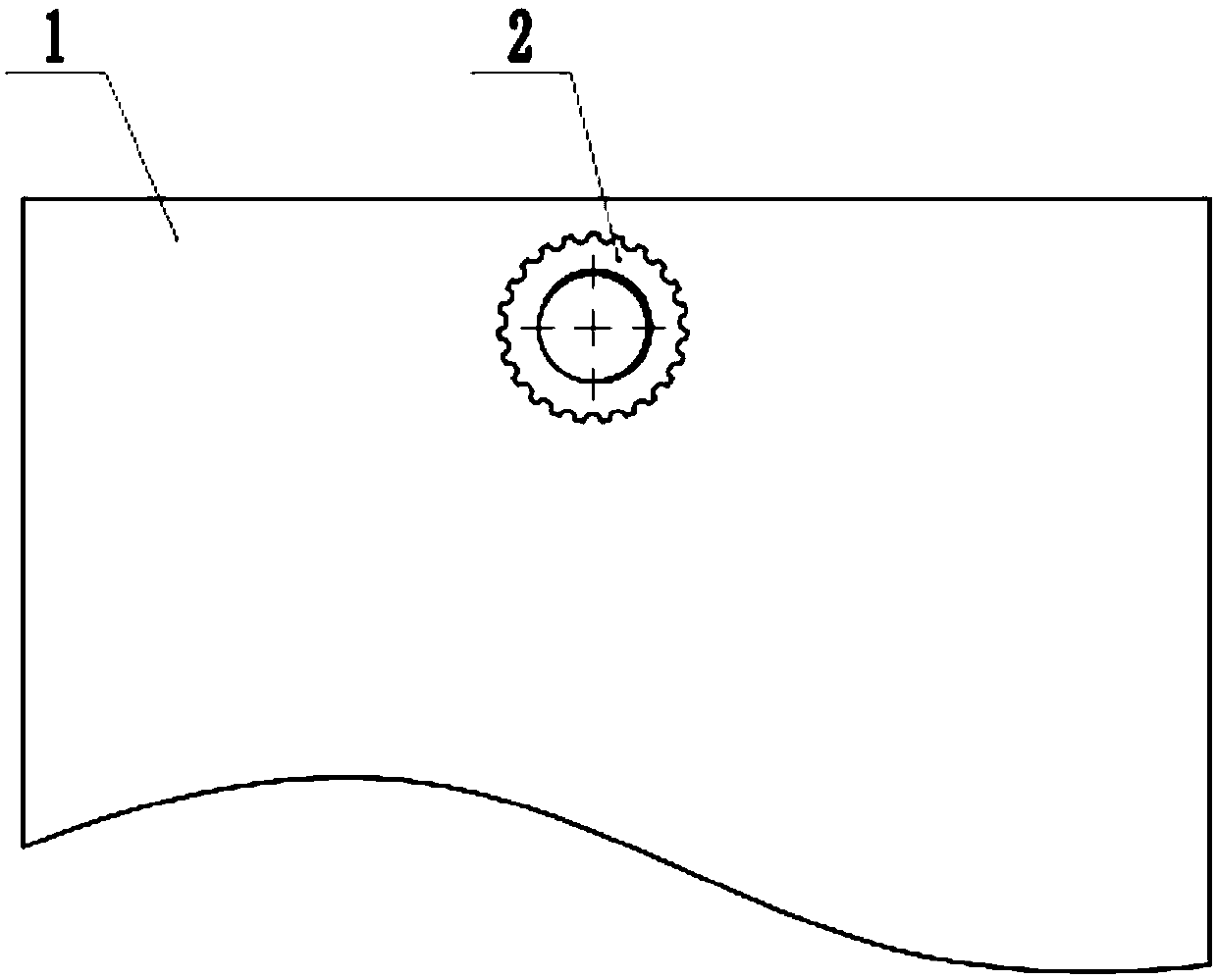

[0032] Such as figure 1 As shown, a circuit board nut reinforcement device includes a circuit board 1 and a nut 2, the nut 2 is connected to the circuit board 1, the lower end of the nut 2 is provided with a positioning post 3, and the circuit wrench 1 is provided with a positioning hole 101, the positioning post 3 is matched with the positioning hole 101, and the lower end surface of the nut 2 is connected with the circuit board 1 by soldering. In order to prevent the positioning post 3 from rotating in the positioning hole 101, resulting in weak welding, the positioning post 3 is designed It is a prism structure, and the shape of the positioning hole 101 matches the positioning column 3 .

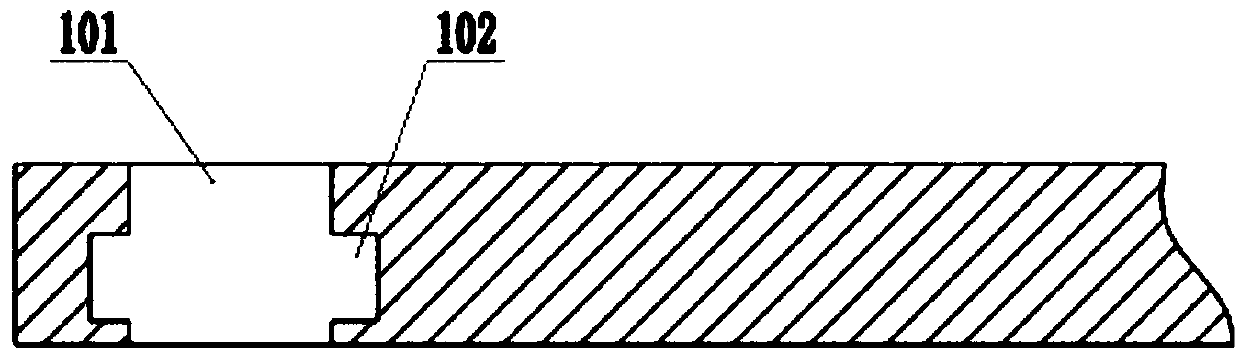

[0033] In order to avoid long-term use, the welding place becomes loose, and the positioning column 3 falls off from the positioning hole 101, such as figure 2 As shown, the inner wall of the positioning hole 101 is provided with an anti-off groove 102, and the number of the anti-off gr...

Embodiment 2

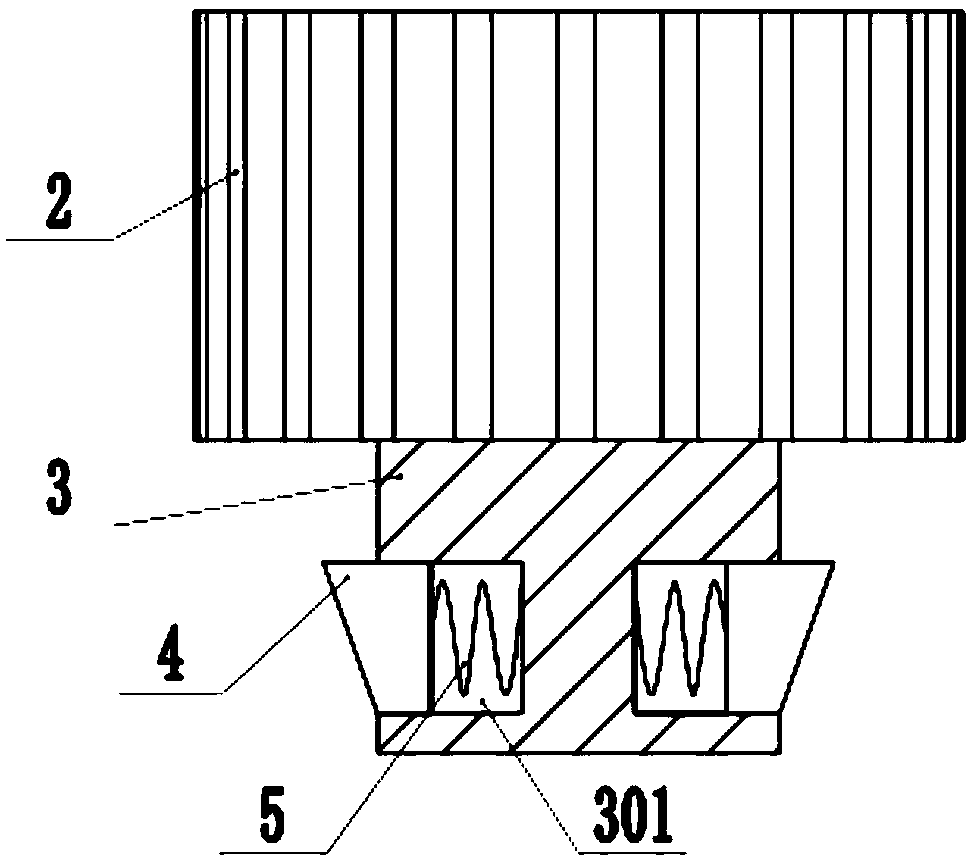

[0037] This embodiment is compared with the first embodiment, the difference lies in the difference between the anti-off block 4 and the anti-off hole 301 .

[0038] Such as Figure 5 As shown, the anti-off hole 301 is a through hole, the number of anti-off grooves 102 is two, the two ends of the anti-off hole 301 are provided with inner flanges 302, and the number of the anti-off blocks 4 is two. One, two springs 8 are arranged between the two anti-off blocks 4, such as Figure 6 As shown, the anti-off block 4 includes a slide block 6 and an insert block 7, the slide block 6 cooperates with the inner wall of the anti-off hole 301, the side wall of the insert block 7 cooperates with the inner flange 302, and one end of the slide block 6 matches with the inner wall of the anti-off hole 301 The plug 7 is connected, the other end of the slider 6 is provided with a spring groove 601, and the end of the spring 2 8 is arranged in the spring groove 601 and connected with the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com