Grinding protecting and dust gathering device

A dust, together technology, used in the field of grinding protection and dust capture devices, can solve the problems of large dust particles, large space occupation, high energy consumption, etc., to reduce the pollution area, improve work efficiency, and improve the sanitation environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The patent will be further described in detail below with reference to the drawings and specific embodiments.

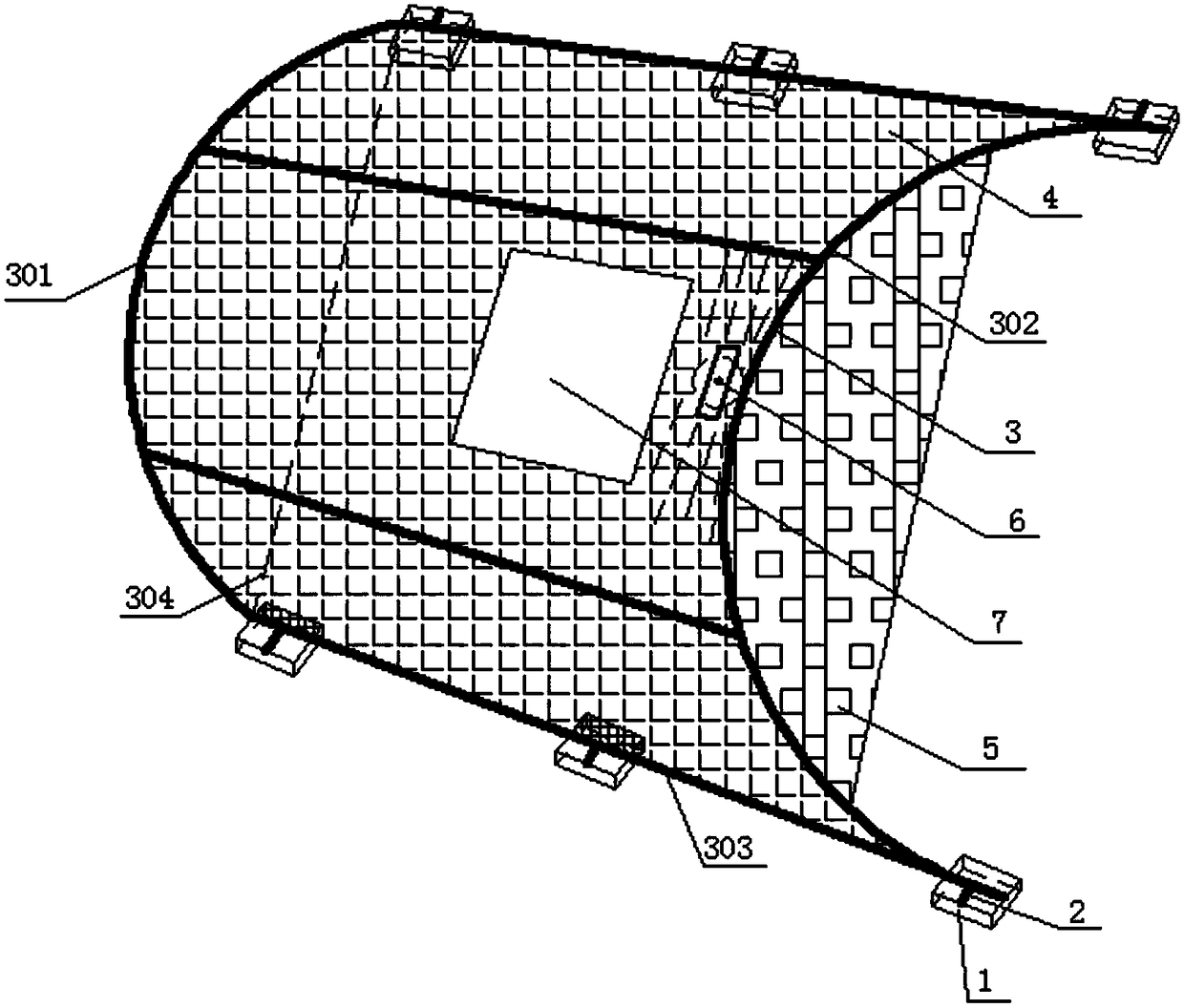

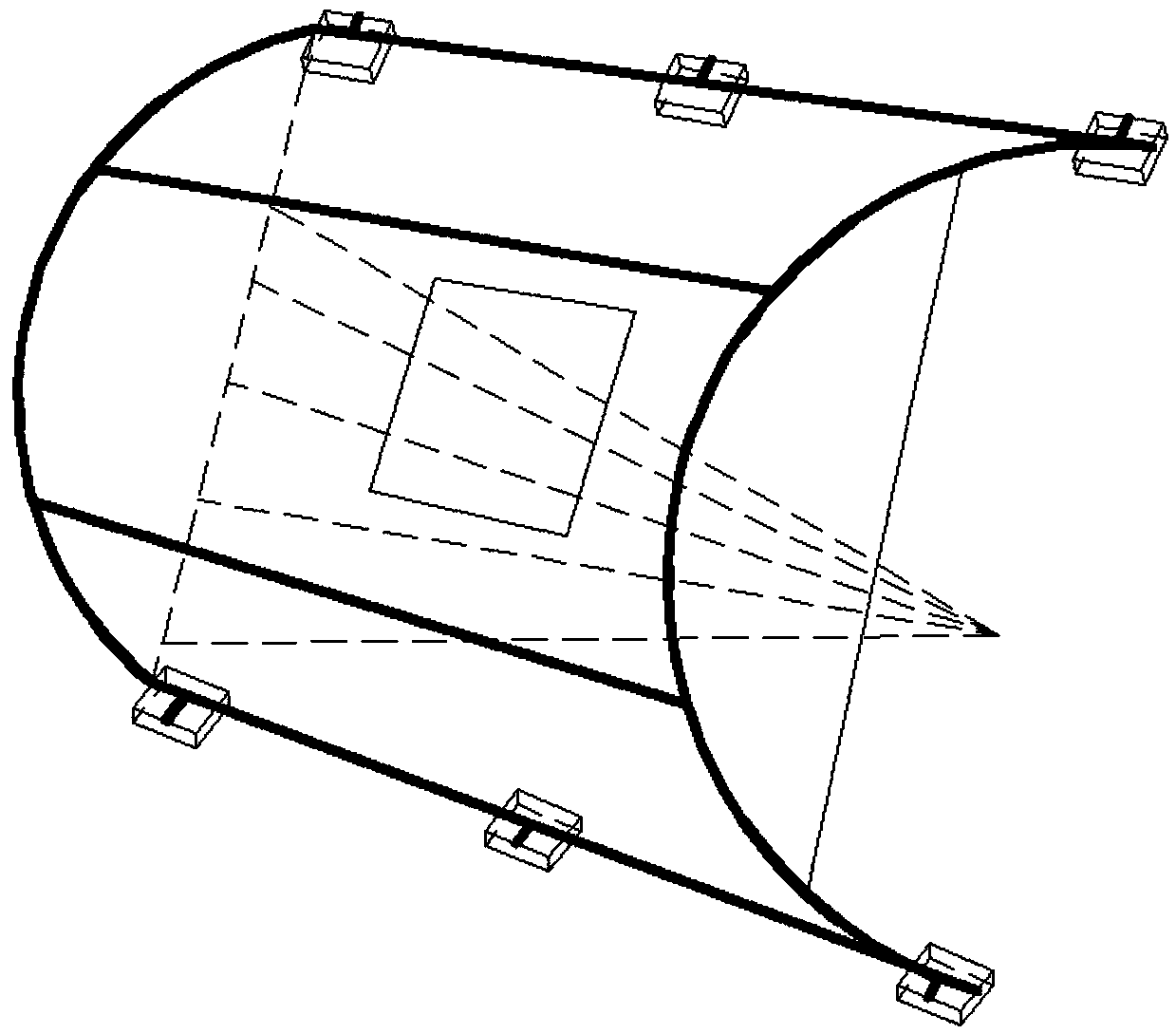

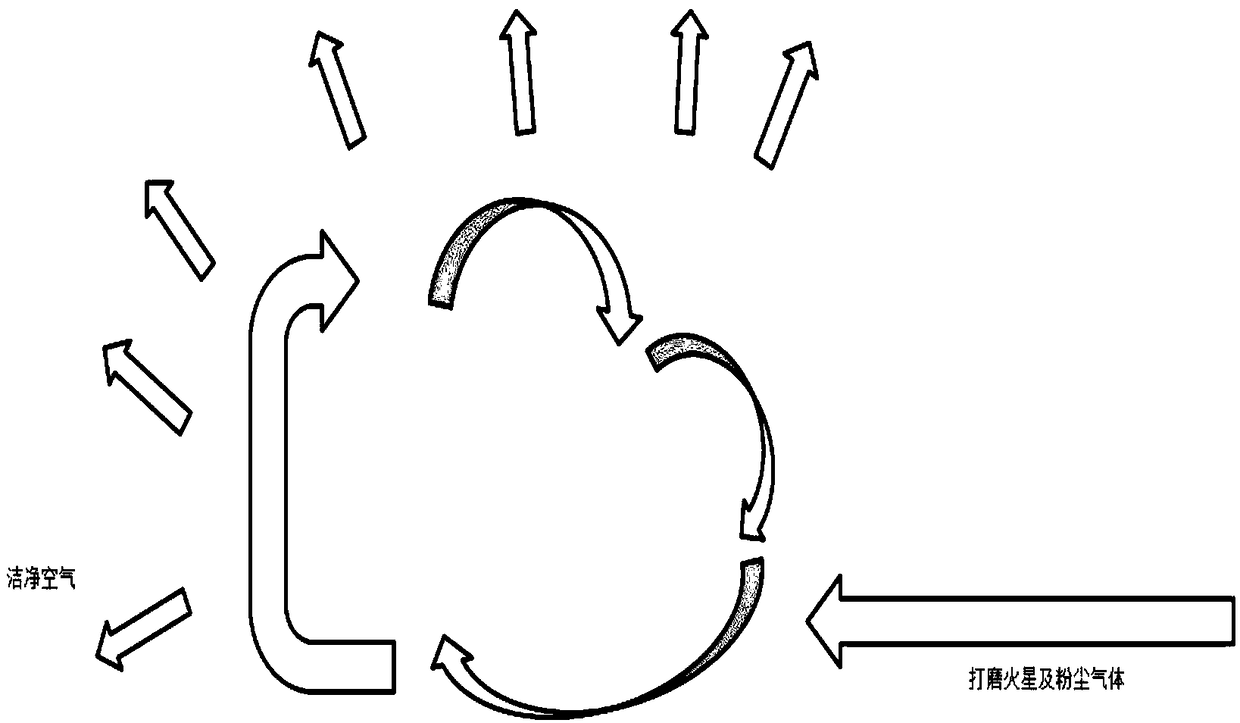

[0018] A polishing protection and dust collection device, such as figure 1 As shown, it includes a magnet 1, a magnet skeleton link buckle 2, a support skeleton 3; the magnet skeleton link buckle 2 connects the support skeleton 3 and several magnets 1 together. The magnetism of the magnet 1 can be realized during the grinding operation according to actual production requirements Any angle of adsorption on the surface of the casting. The supporting frame 3 is welded into an arched structure by a semicircular frame 301 and a semicircular frame 302 through four cross bars 303, and the two ends of the semicircular frame 301 are welded with braces 304; the arched surface of the supporting frame 3 The semicircular surface of the semicircular bracket 301 is wrapped with a filter covering cloth 4 and tied with iron wire to ensure sealing and filter dust; the filter cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com