Gas exhausting device for injection mold

An exhaust device and injection mold technology, applied in the field of injection mold exhaust device, can solve problems such as inability to close, discharge of molding materials, and unsmooth return of falling chips, and achieve the effect of improving durability and life, and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, an embodiment according to the present invention will be described in more detail with reference to the accompanying drawings.

[0047] The description with reference to the drawings is for easier understanding of the present invention, and the scope of the present invention is not limited thereto. Also, when describing the present invention, detailed descriptions related to known technologies will be omitted if they may obscure the gist of the present invention.

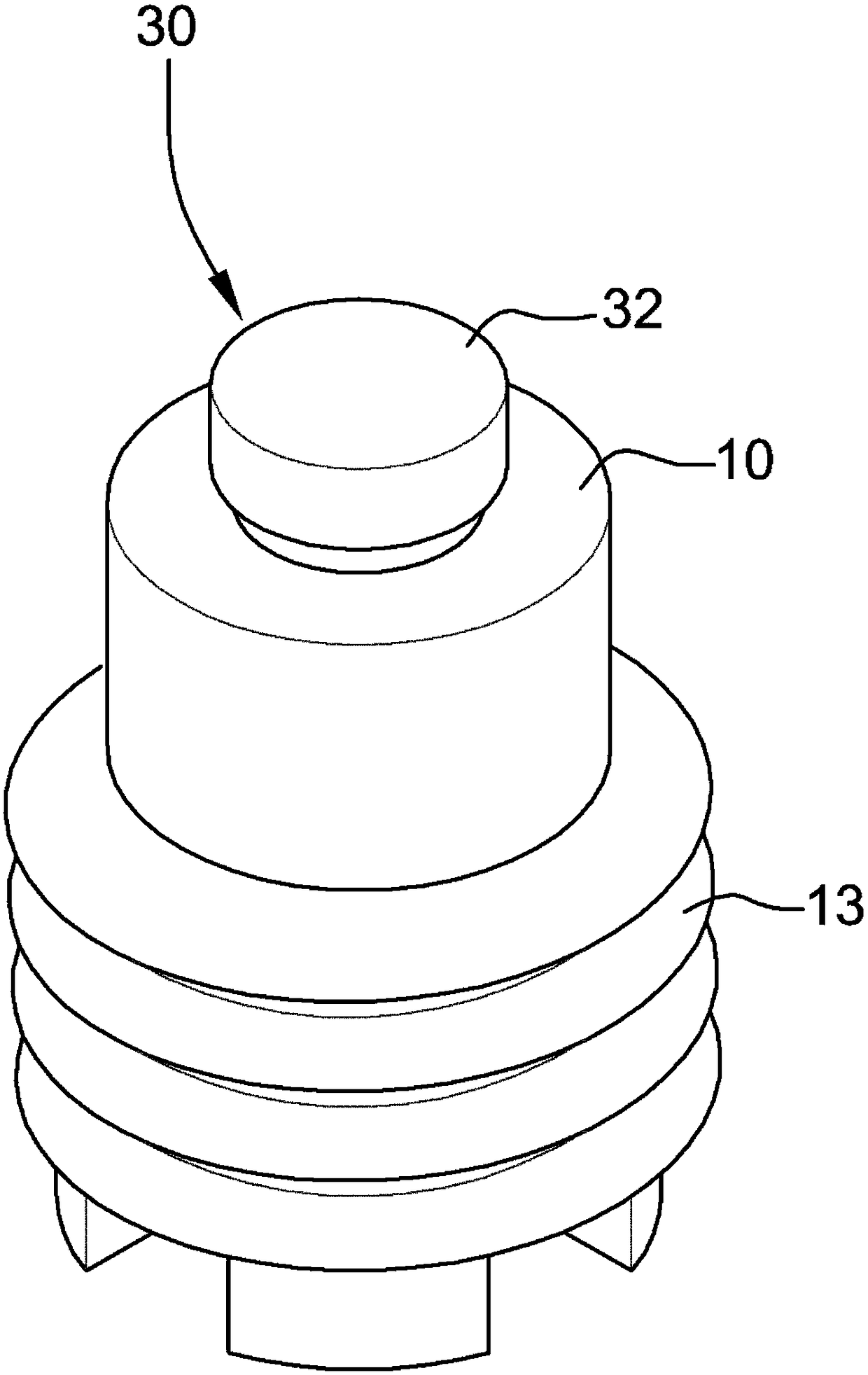

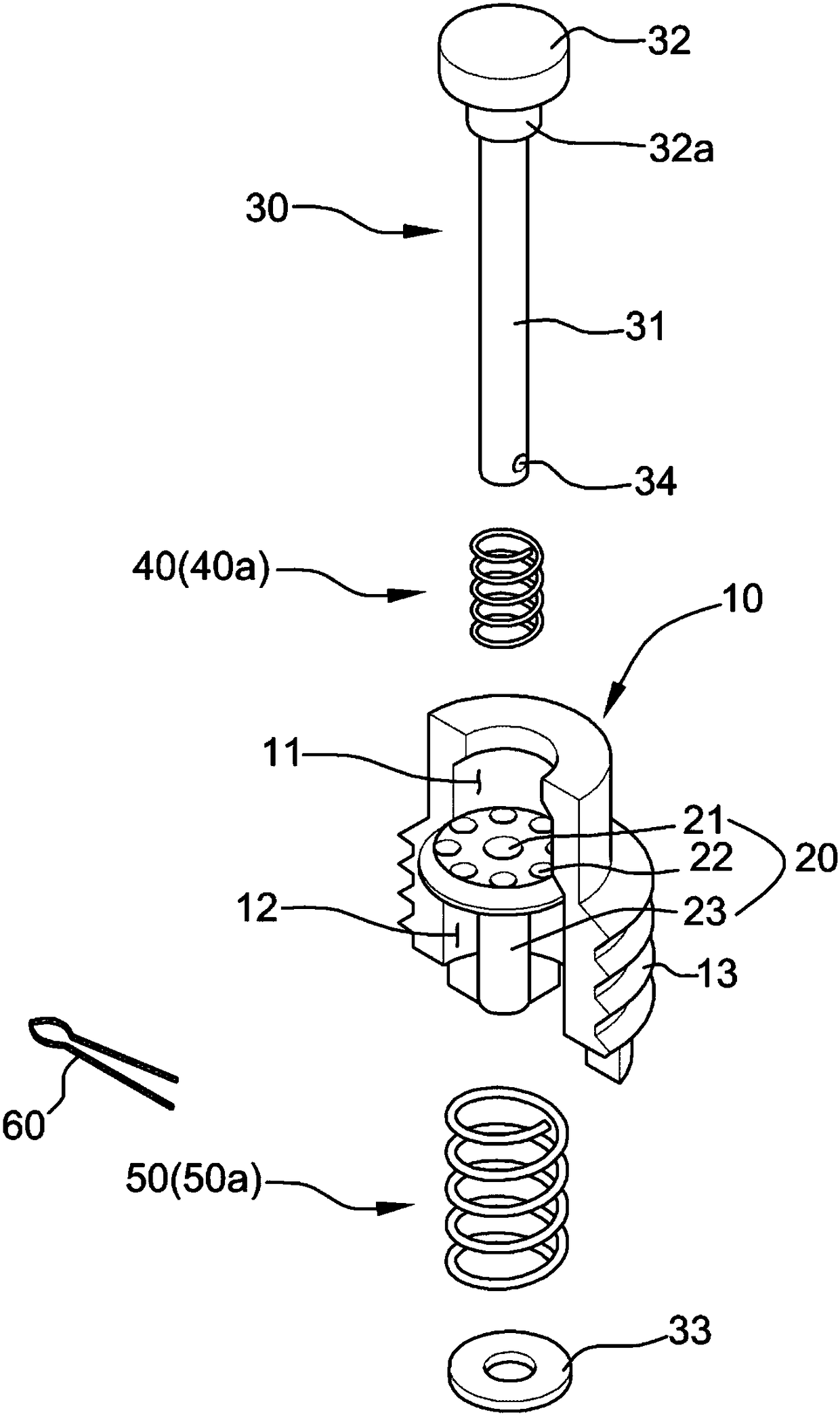

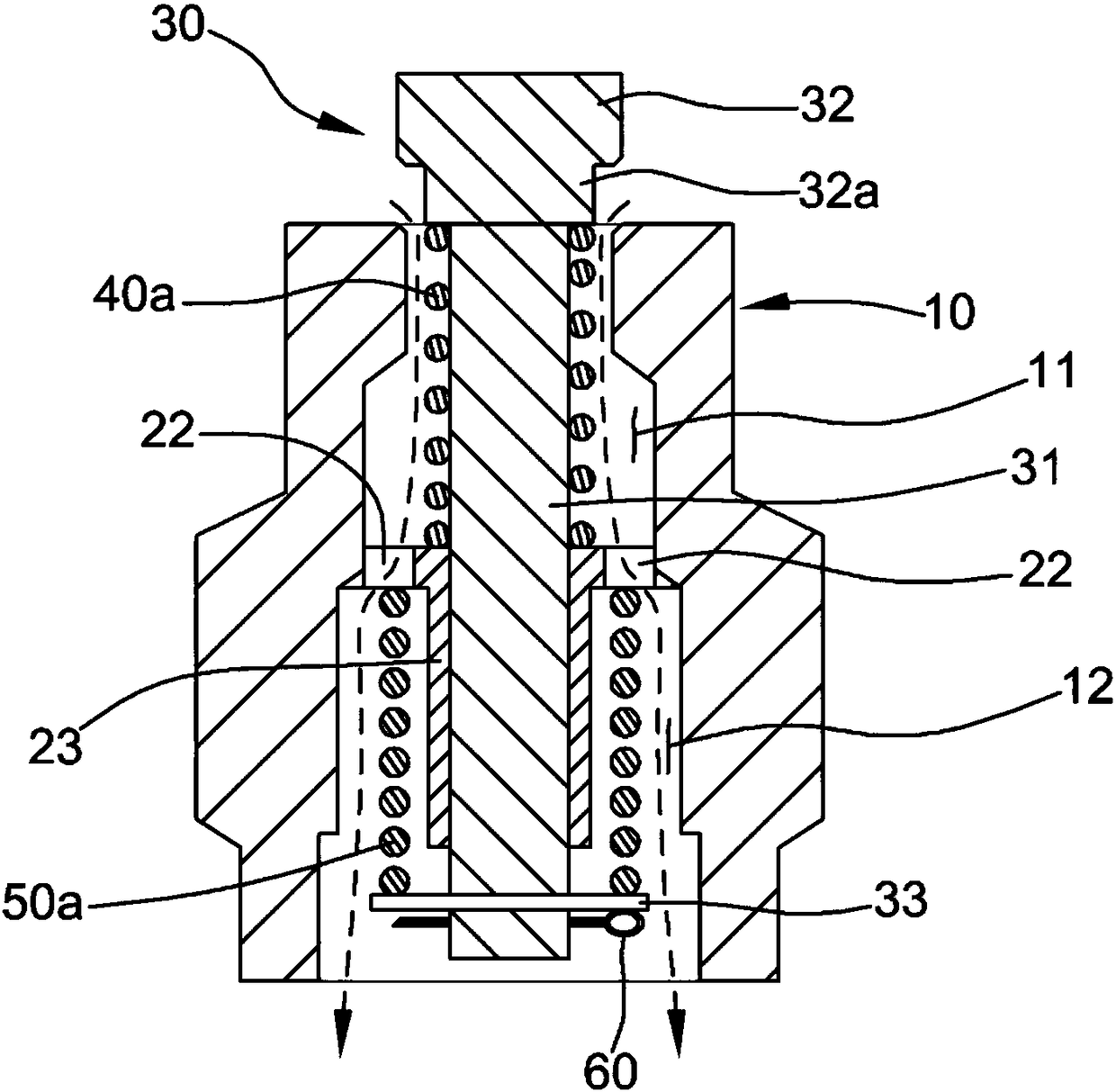

[0048] figure 1 is a perspective view of an injection mold exhaust device according to an embodiment of the present invention; figure 2 for in figure 1 The exploded perspective view of the present invention illustrated in; image 3 for in figure 1 A cross-sectional view of the invention illustrated in .

[0049] As shown in the figure, the injection mold exhaust device according to the present invention is to discharge the air or gas remaining in the cavity of the injection mold, and genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com