Processing technology for wire glass handicraft

A processing technology and a technology for wired glass, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient processing flow of glass products, lack of inspection, control, and product qualification rate of glass products, etc. Achieve the effect of improving transparency and melting speed, ensuring glass quality, and improving internal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

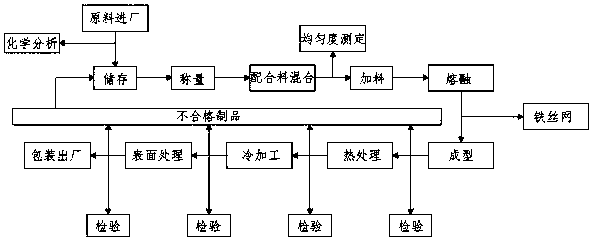

[0018] see figure 1 Shown, a kind of wired glass handicraft processing technology comprises the following steps:

[0019] Step 1: The raw materials are transported into the factory and subjected to chemical analysis, and then stored in the factory building;

[0020] Step 2: Weigh a certain amount of main raw materials and auxiliary raw materials, and then uniformly mix them together and accurately detect the uniformity; add the uniformly mixed raw materials into the injection mold, and then heat to high temperature to melt; the main raw materials are mainly Including quartz sand, soda ash, limestone, feldspar, etc., the main raw materials should be iron-removed before production; auxiliary raw materials mainly include clarifiers, colorants, decolorizers, opacifiers and fluxes, and iron removal of raw materials Treatment can effectively remove iron impurities in the raw materials to ensure the quality of the glass. By adding a variety of auxiliary raw materials, the transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com