Method for testing residual intensity of bituminous mixture

A technology of asphalt mixture and testing method, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., and can solve problems such as accelerated damage of pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

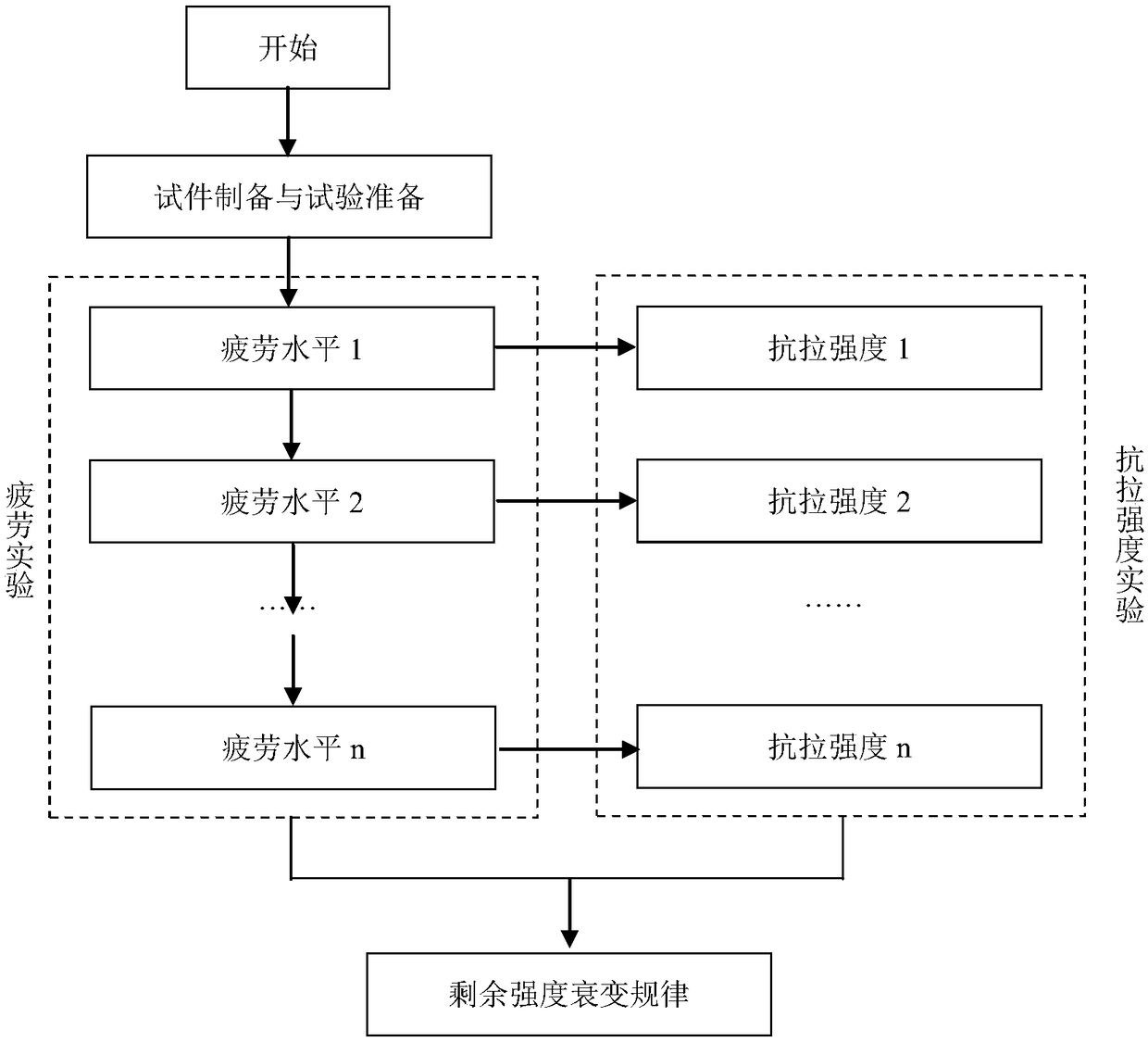

[0025] Embodiment 1: as figure 1 As shown, a method for decay law of residual strength of asphalt mixture includes the following steps:

[0026] 1) Prepare matrix 70# asphalt AC-20 mixture according to T 0739-2011 four-point bending fatigue life test requirements of asphalt mixture in JTG E20-2011 highway engineering asphalt and asphalt mixture test regulations. The test temperature was 15°C, the loading frequency was 10 Hz, the controlled strain loading mode was adopted, and the loading level was 800 με. Carry out the first set of fatigue tests to obtain the fatigue life N of the current mixture f = 2400 times.

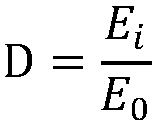

[0027] The fatigue damage of the material is characterized by the stiffness of the specimen, which takes the following form:

[0028]

[0029] In the formula: D is the fatigue damage variable characterized by stiffness, E i is the stiffness of the specimen when it is loaded in the i-th cycle, E 0 is the initial stiffness of the specimen before loading.

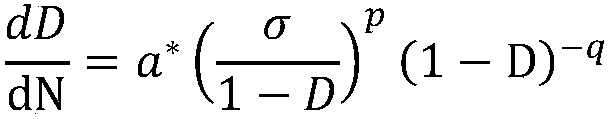

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com