A wind turbine generator winding fault intelligent diagnosis system and method

A wind turbine, intelligent diagnosis technology, applied in the direction of electrical winding testing, etc., can solve problems such as long fault recovery period, broken rotor lead wire, and inability to real-time monitoring, etc., to achieve accurate diagnosis results, shorten downtime, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

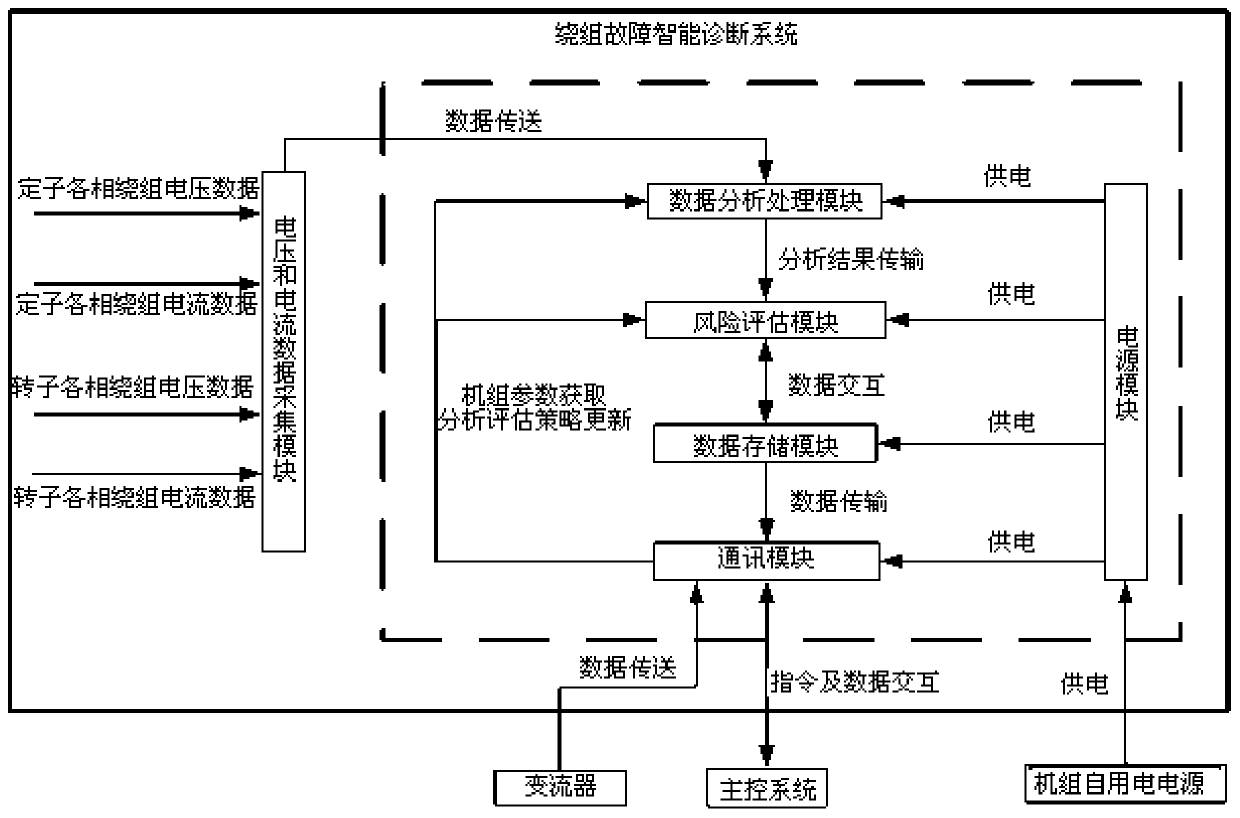

[0034] Refer to attached figure 1 As shown, the wind turbine generator winding fault intelligent diagnosis system of the present invention includes a data acquisition module, a data analysis and processing module, a risk assessment module, a data storage module, a communication module and a power supply module.

[0035] The data acquisition module is used to collect the voltage and current data of each phase winding of the stator and rotor of the wind turbine generator in real time, and transmit the collected data to the data analysis and processing module.

[0036] Wherein, the data acquisition module in this embodiment is a voltage and current data acquisition device. The voltage and current data acquisition device uses induction coils installed on the phase cables connecting the generator and the whole machine to measure the voltage and current data of each phase winding of the stator and rotor in real time. Of course, the communication module can also be connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com