Seal Member and electrical connector

A technology for sealing members and electrical connectors, which is applied in the direction of vehicle connectors, connections, and parts of connecting devices, etc., to achieve the effects of suppressing manufacturing costs, reducing the number of parts, and suppressing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

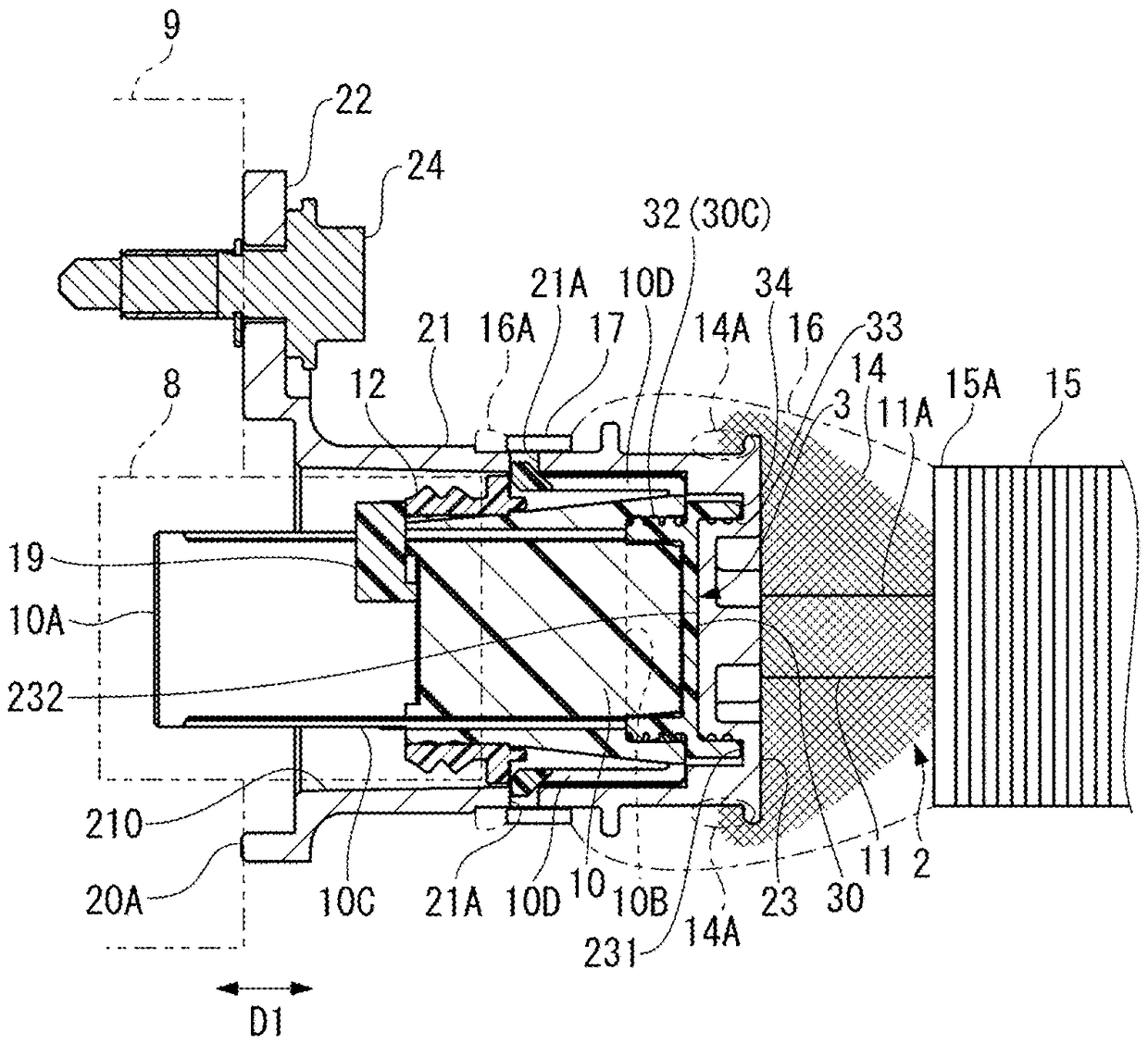

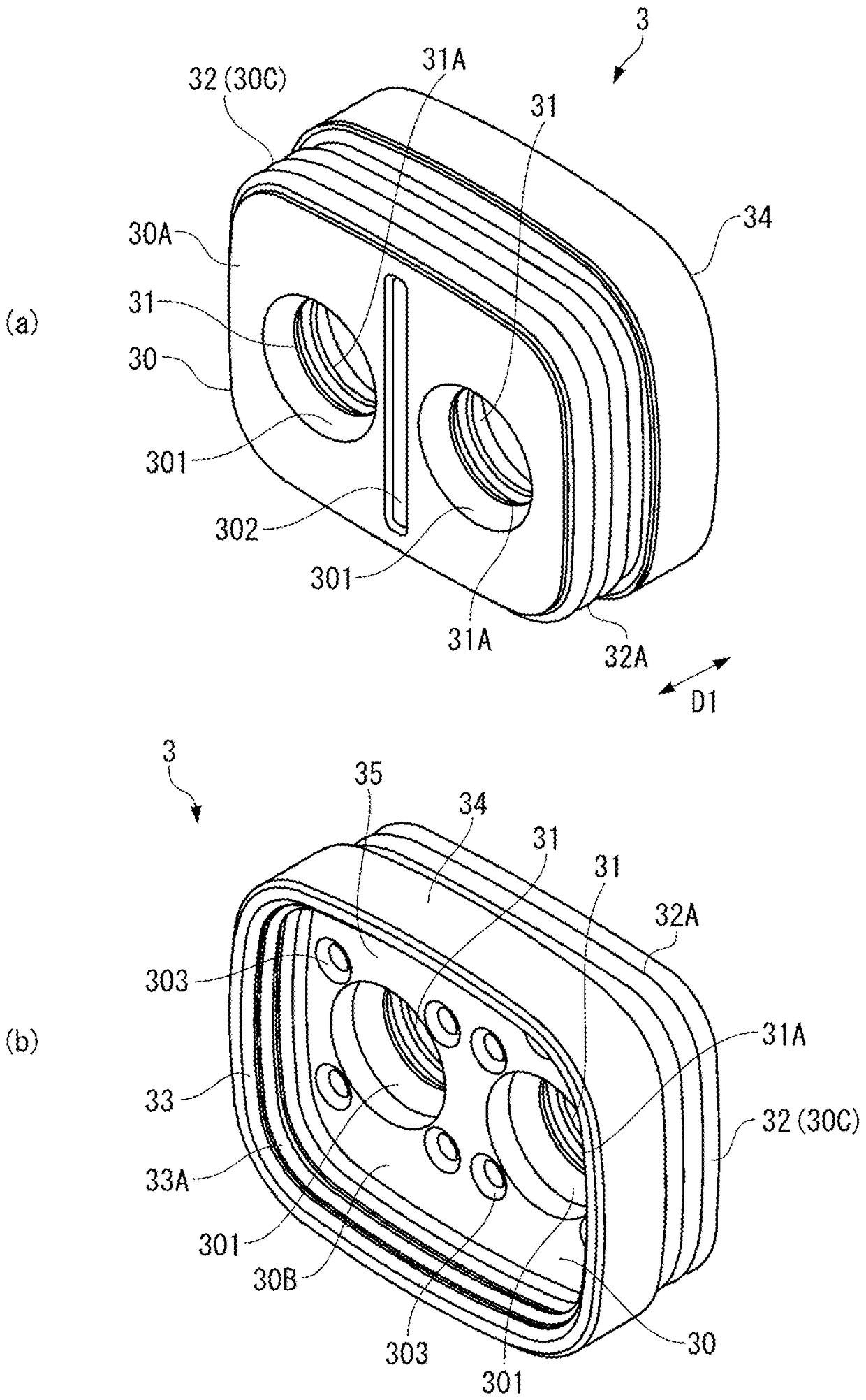

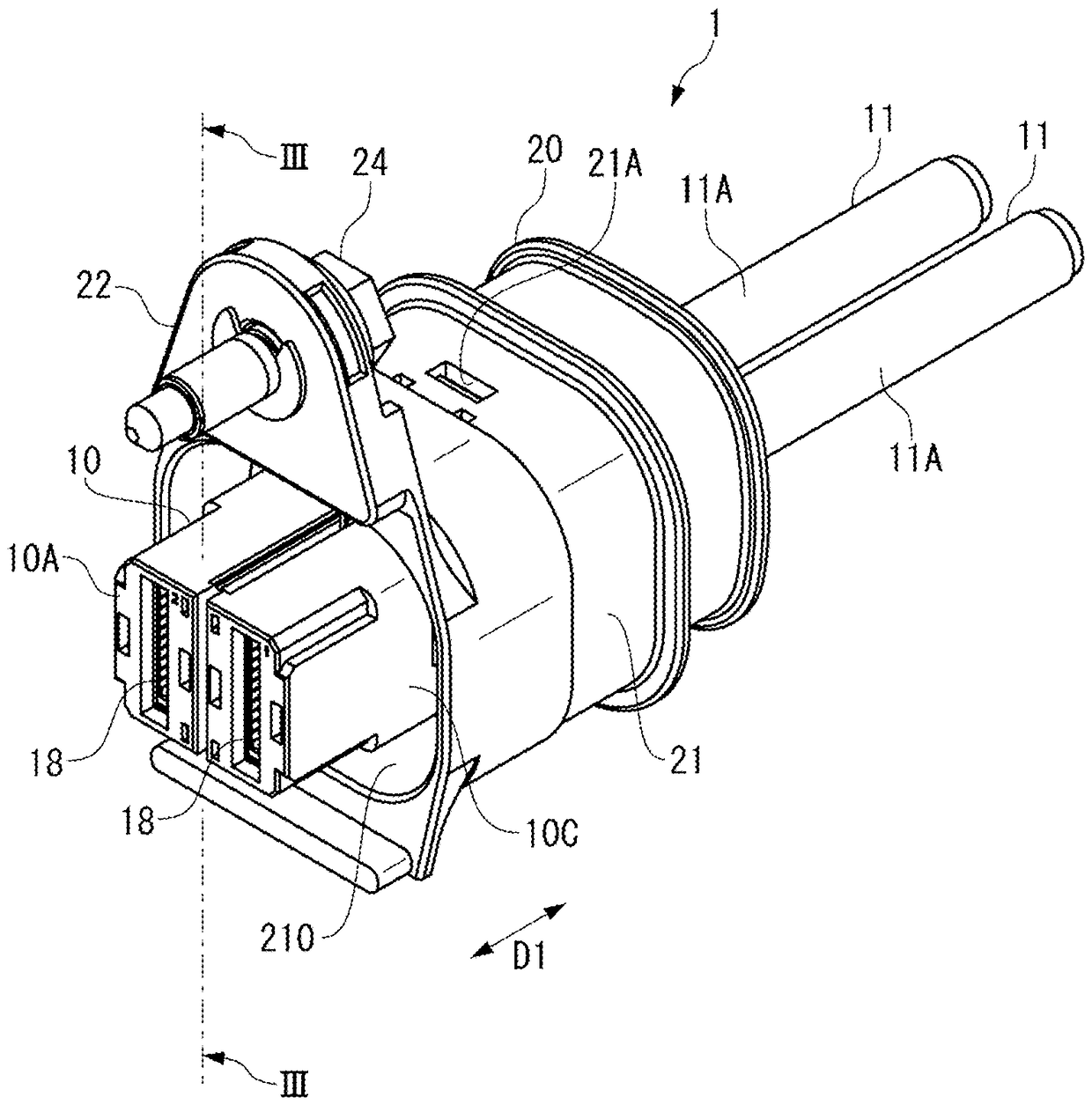

[0030] figure 1 and figure 2 The shown electrical connector 1 (plug connector) includes: a housing 10 from which two electric wires 11 are drawn; a shell 20 for electromagnetic shielding; a sealing member 3 ( image 3 and Figure 4 ); and the fitting part seal 12 ( image 3 ).

[0031] In this specification, the side where the electric wire 11 is drawn out of the electrical connector 1 is defined as "rear", and the opposite side, that is, the side that is mated with the mating connector (cover connector) along the mating direction D1 is defined as "front". . With respect to mating connectors, typically part of the device housing ( image 3 The metal components 9) are assembled.

[0032] The electrical connector 1 and the mating connector are suitable for electrical connection of high-voltage equipment such as a PCU (Power Control Unit) mounted on a vehicle. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com