High-frequency transformer laser peeling machine

A technology of high-frequency transformers and stripping machines, which is applied in the direction of cable installation devices, electrical components, and equipment for dismantling/armouring cables, etc., which can solve the problems of braiding layer or inner conductor damage, low efficiency of manual stripping, etc., and improve stripping efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

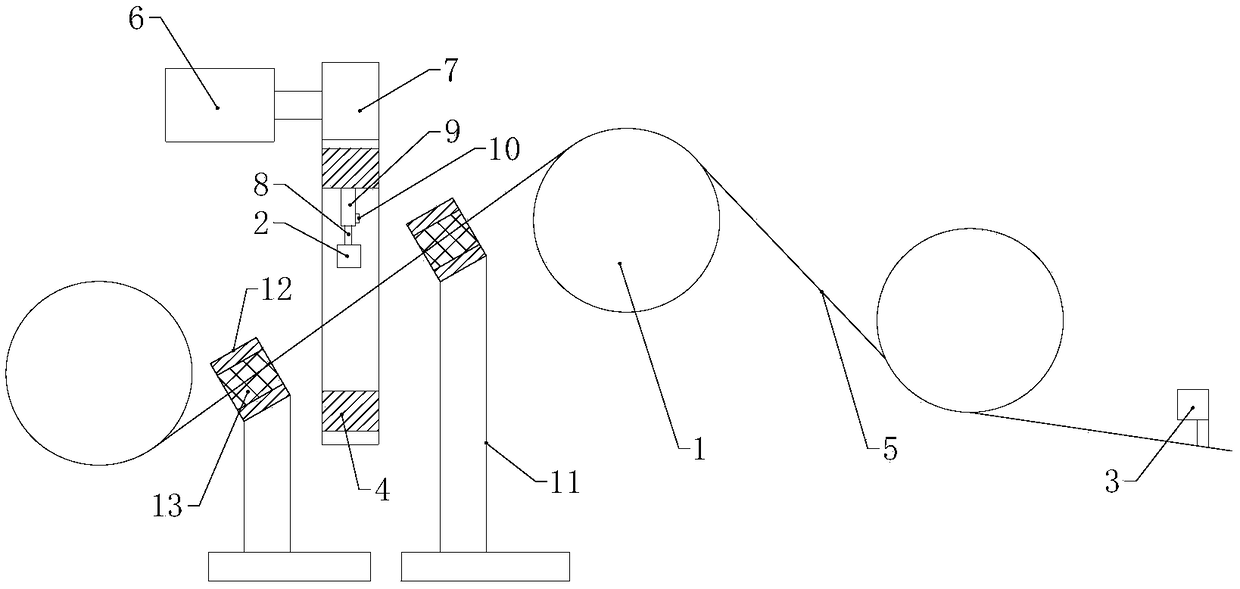

[0012] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: the high-frequency transformer laser peeling machine of the present embodiment includes a cable conveying roller 1, a laser generator 2 and a skin scraper 3, and also includes a placement ring 4 driven by a driving structure, and the laser generator is arranged on a placement The inner wall of the ring, the cable 5 passes through the set ring, the driving structure includes a motor 6 and a gear 7 fixedly sleeved on the output shaft of the motor, the outer wall of the set ring is provided with a ring gear, and the gear is meshed with the ring gear for transmission, and the motor and the placement circle are all supported by corresponding supporting structures, which is prior art and will not be introduced in detail. In the laser stripping machine with this structure, the laser generator emits laser light to cut the cable cortex. During the cutting process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com