Wheel for a commercial vehicle, and use thereof

A technology for commercial vehicles and wheels, which is applied in the direction of wheels, wheel manufacturing, web-type wheels, etc., can solve the problems of wheel weight burden, achieve high alternating bending fatigue limit, and optimize the design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

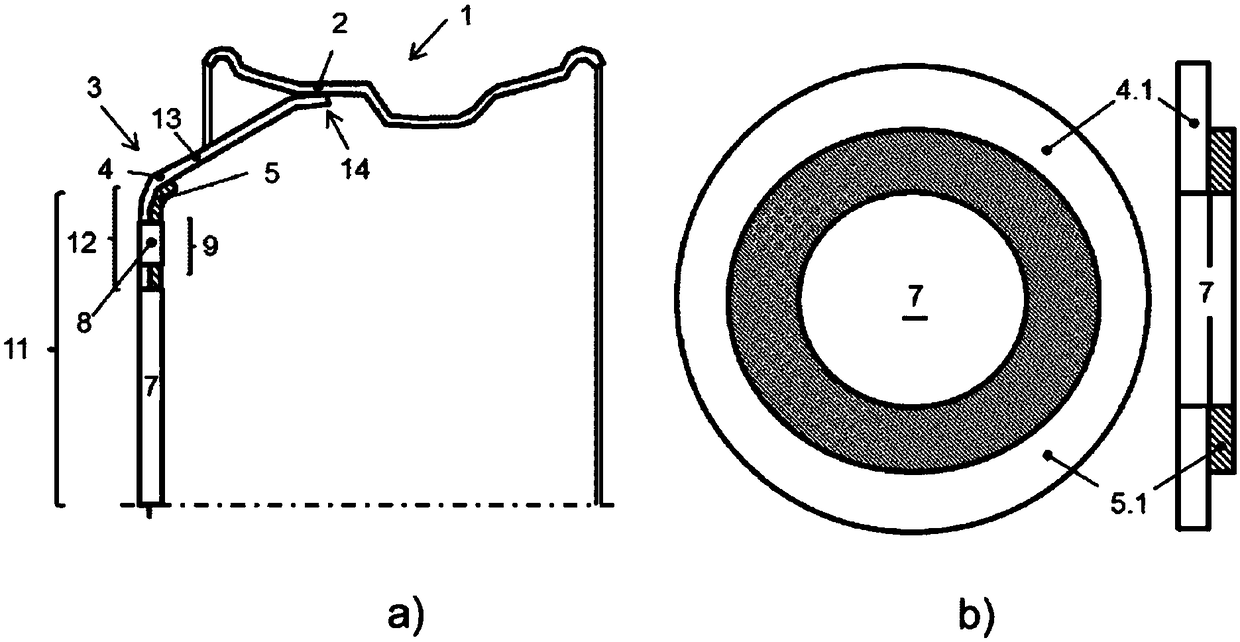

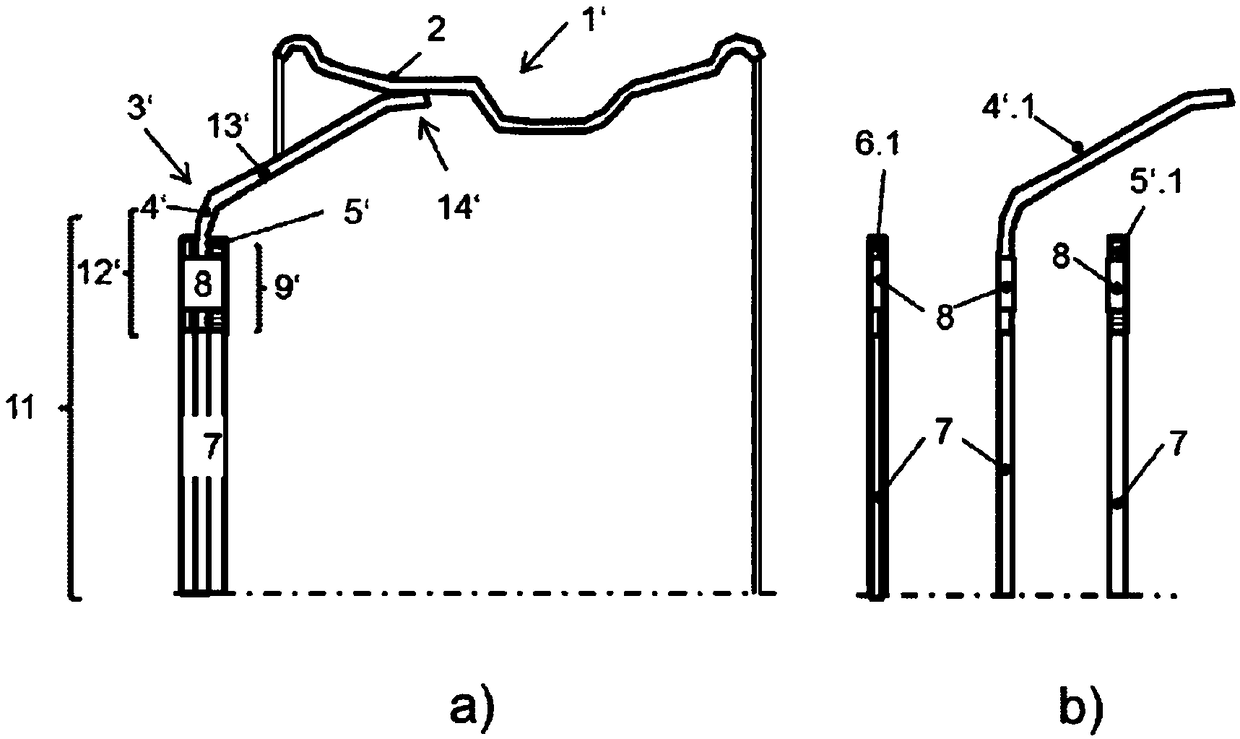

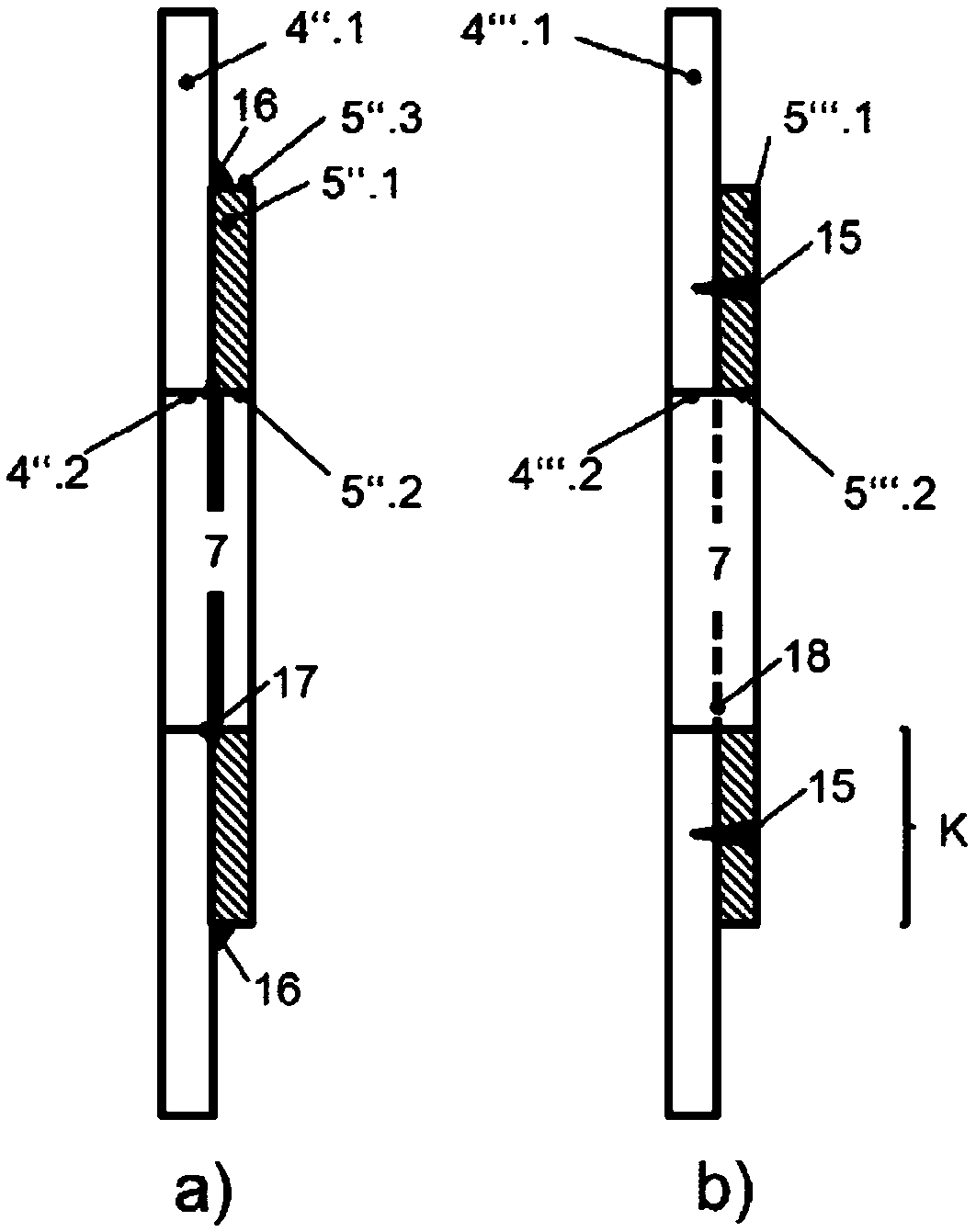

[0025] figure 1 a) shows a schematic sectional view of a first embodiment of a commercial vehicle wheel (1) according to the invention, wherein only the axis of symmetry (10) of the commercial vehicle wheel (1) is shown due to the rotationally symmetrical design on the upper area. The commercial vehicle wheel (1) comprises a rim (2) for accommodating a tire, not shown, and a disc (3) connected to the rim (2). The wheel (3) consists of two parts (4,5) connected to each other. The mutual connection can be material fit, form fit and / or force fit. The wheel disk (3) is substantially shell-shaped. The wheel comprises a central region (11) with a central opening (7) and a surrounding web region (12), in which a seat for accommodating, not shown, surrounding the central opening (7) is arranged. Multiple openings for connecting devices such as pins and / or bolts. At least a part of the web region (12) forms a connection region (9) for detachable connection to the wheel carrier. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com