Punching die and punching method for rectangular tube

A technology for punching rectangular tubes, applied in the direction of perforating tools, manufacturing tools, feeding devices, etc., can solve the problems of rectangular tube side wall deformation, affecting punching quality, and inability to punch holes, so as to improve quality and improve punching The effect of positioning accuracy and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

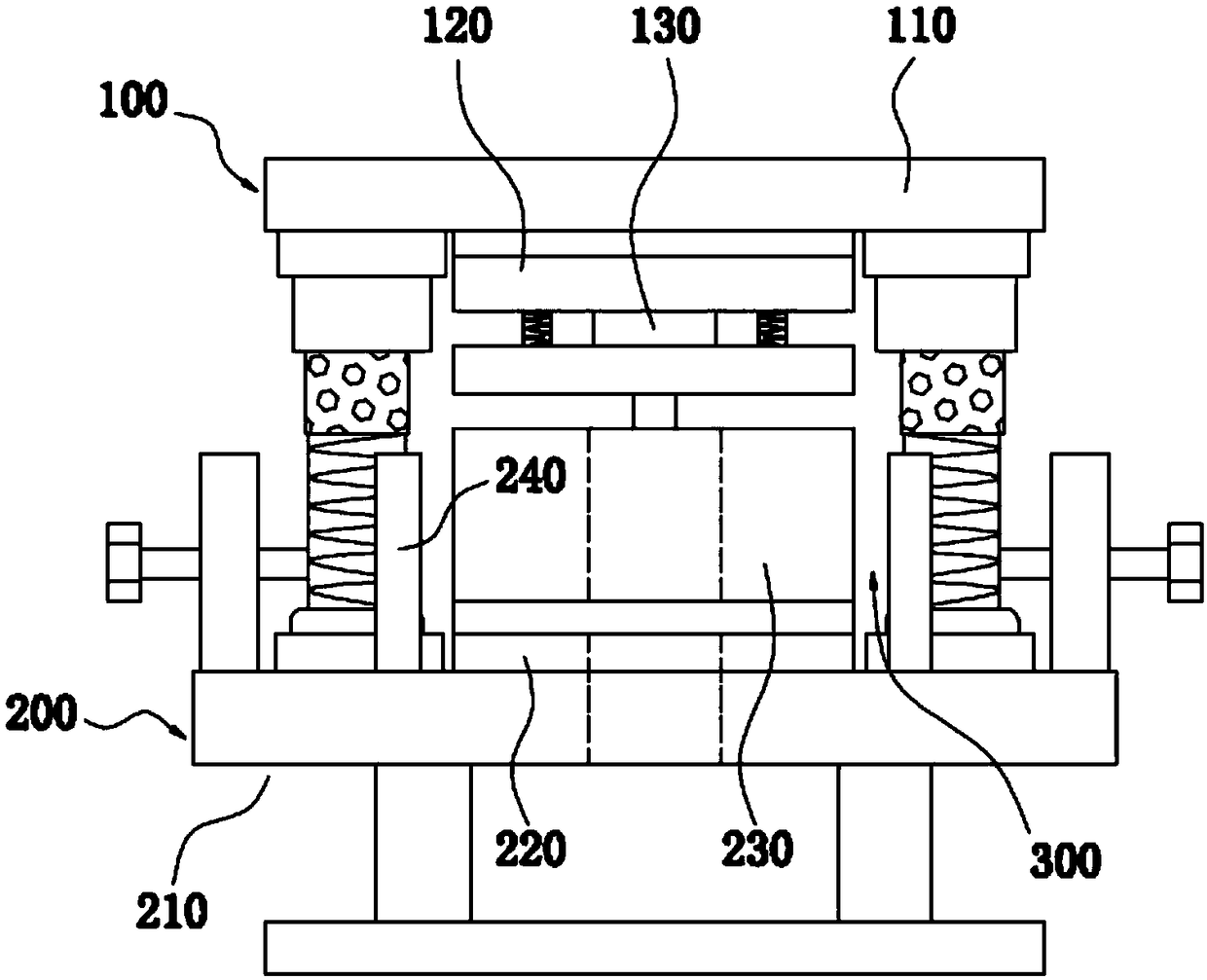

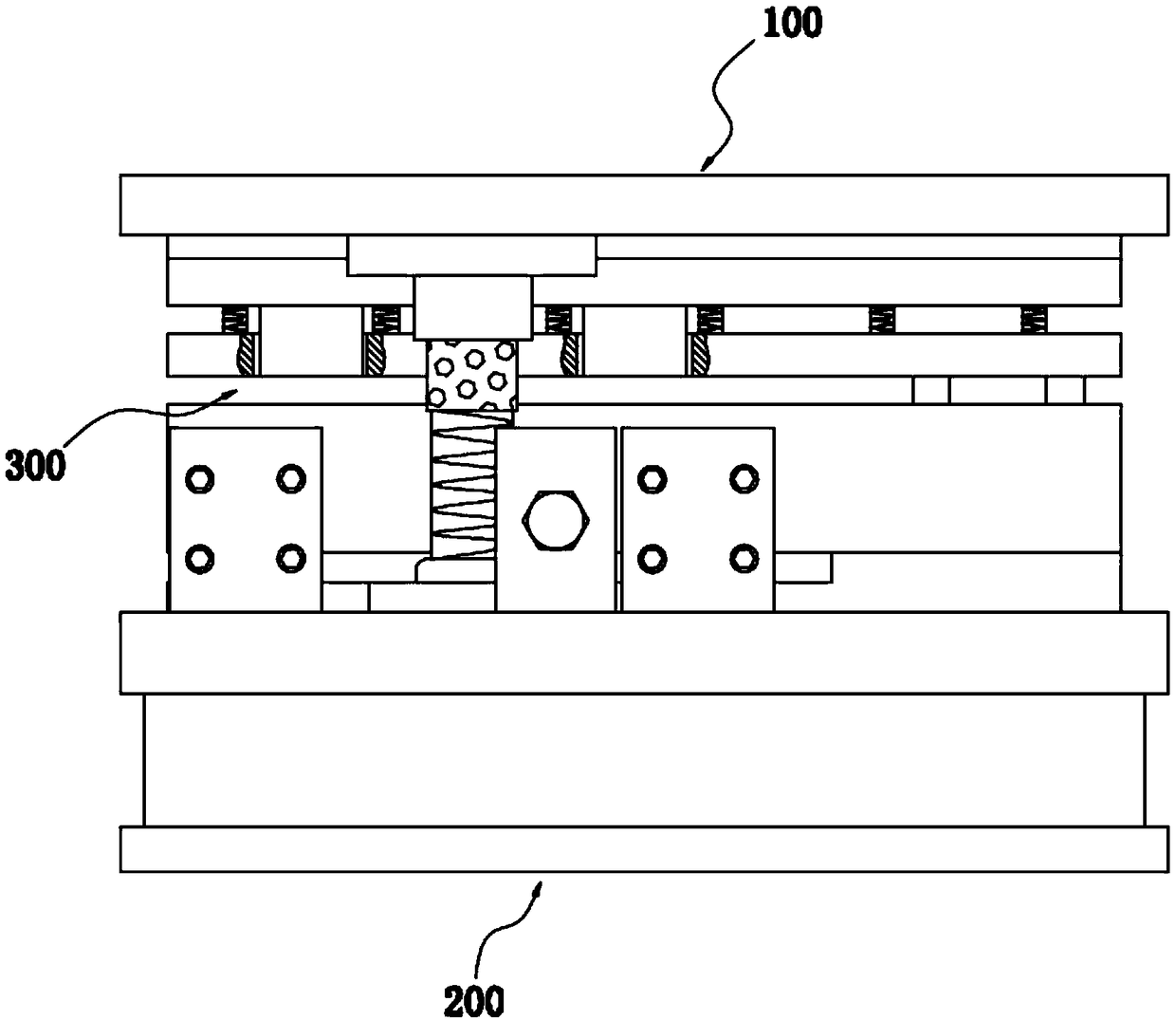

[0050] A rectangular tube punching die, such as figure 1 , 2 As shown, an upper mold assembly 100 and a lower mold assembly 200 are included.

[0051] Such as figure 1 , 2 As shown, the upper mold assembly 100 includes an upper mold plate 110, an upper mold core seat 120 and several upper mold cores 130, the upper mold core base 120 is fixed on the bottom of the upper mold plate 110, and the upper mold core 130 is fixed At the lower end of the upper mold core base 120; the upper mold plate 110 and the upper mold core base 120 are both flat plates; the upper mold core 130 can be cylindrical or polygonal, or other Cylindrical shape with irregular cross-section, such as figure 1 , 2 As shown, the upper mold core 130 is cylindrical and is used to process circular holes; the number and arrangement of the upper mold core 130 are set according to the number and position of the processed holes, which can be one or two or three Above, when there are more than two upper mold cores...

Embodiment 2

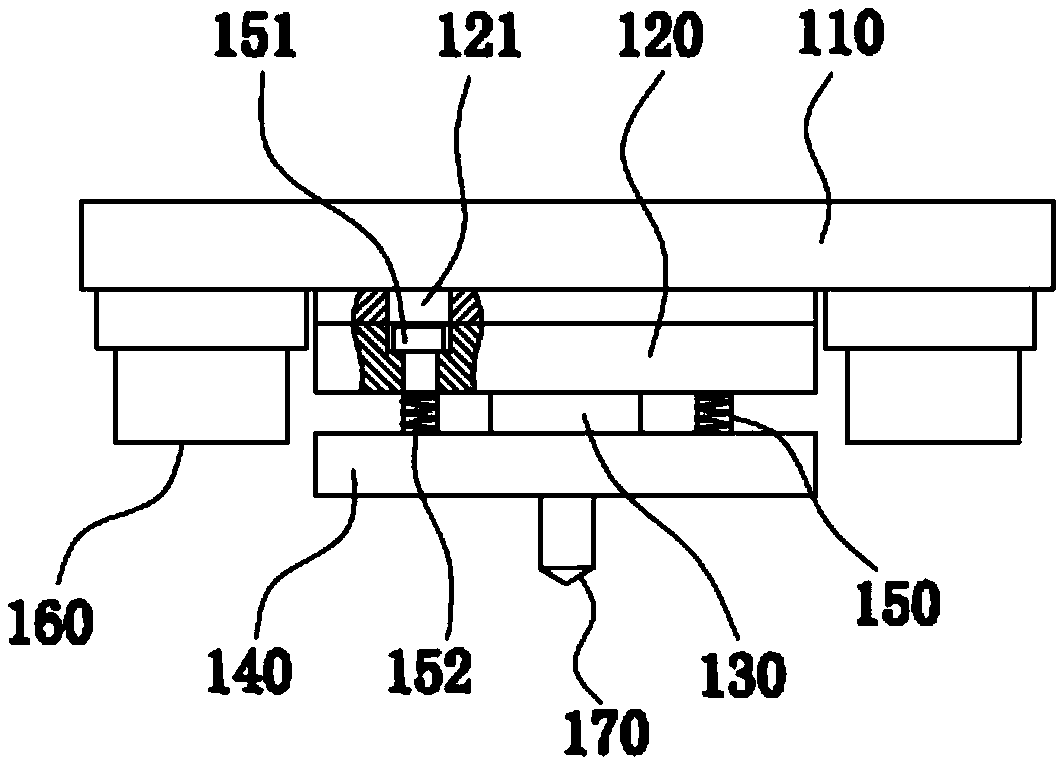

[0057] A kind of rectangular pipe punching die of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are, as image 3 , 4 , 5, the lower mold assembly 200 is provided with a guide column 260, and the guide column 260 is fixed on the support seat 210; as Figure 6 , 7 As shown in , 8 , the upper mold assembly 100 is provided with a guide sleeve 160 matched with the guide column 260 , and the guide sleeve 160 is fixed on the bottom of the upper mold 110 . The number of the guide post 260 and the guide sleeve 160 is more than one. In this embodiment, there are two guide posts 260 and the guide sleeve 160, and they are arranged symmetrically, so that the positioning and guidance are more stable.

[0058] A kind of rectangular pipe punching die of this embodiment, by setting the guide sleeve 160 and the guide post 260 that cooperate with each other between the upper die assembly 100 and the lower die assembly 200, can play the mold cla...

Embodiment 3

[0060] A kind of rectangular pipe punching die of the present embodiment, basic structure is the same as embodiment 1 or 2, and difference and improvement are, as Figure 6 , 7 As shown in . The positioning mechanism 250 can be a manually adjusted positioning mechanism, or a hydraulically driven automatic positioning mechanism, or other feasible positioning mechanisms. In this embodiment, it is a manually adjusted positioning mechanism, which has a simple structure and low cost;

[0061] The number of the positioning mechanism 250 is more than one; in this embodiment, as Figure 6 , 7 , 8, there are two manually adjustable positioning mechanisms 250, which are symmetrically arranged on the left and right sides of the lower core seat 220, and are located between the front and rear core holes 231. When only a single hole needs to be punched, By adjusting the position limit of the positioning mechanism 250, the insertion depth of the end of the rectangular tube to be processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com