Constructed wetland system for sewage treatment

A technology for constructed wetland system and sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of shortened operating life, reduced wetland water conservancy load, easy blockage of subsurface wetlands, etc. problems, to achieve the effect of reducing clogging problems, high processing load, and eliminating clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

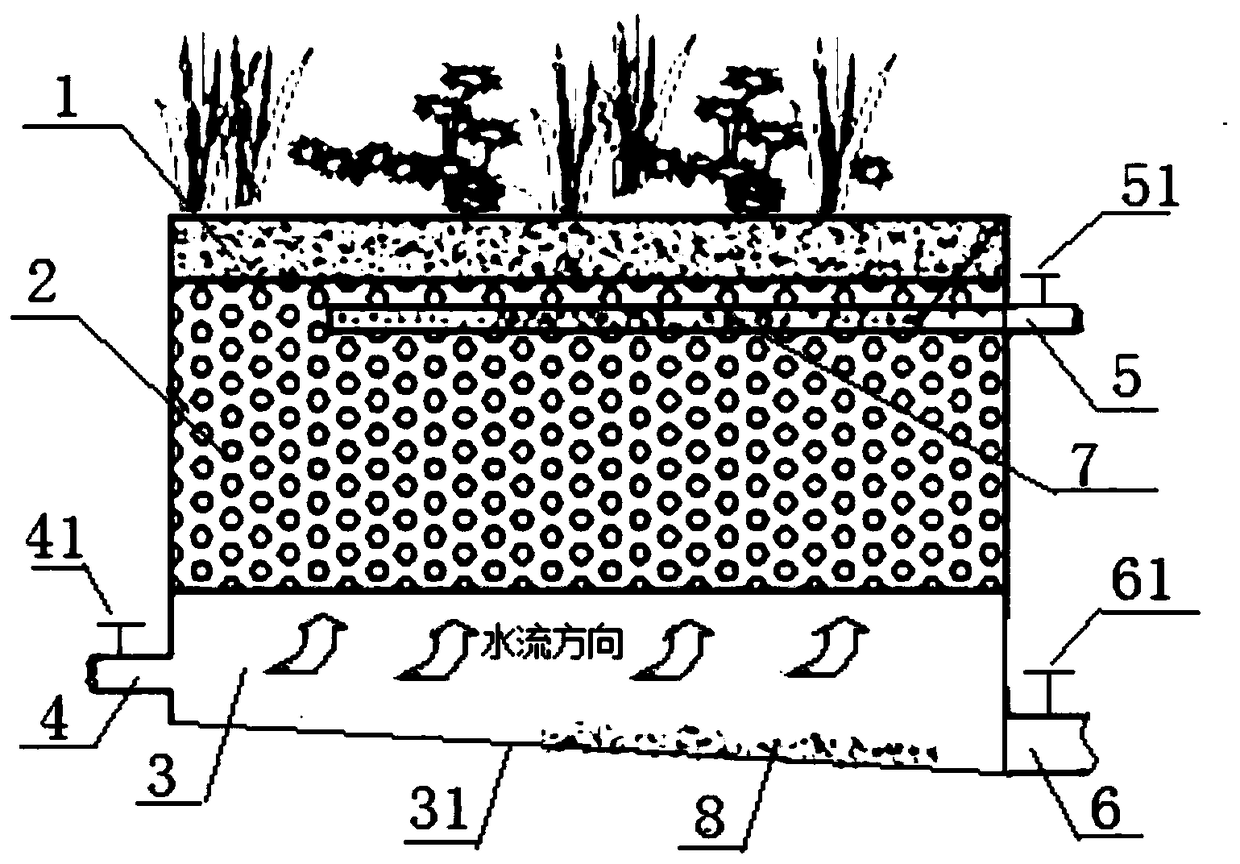

[0024] A constructed wetland system for sewage treatment, such as figure 1 As shown, it includes a vertical subsurface wetland and a reservoir 3 arranged below the vertical subsurface wetland; the bottom surface of the reservoir 3 is an inclined bottom surface 31, and the side wall of the reservoir connected to the higher end of the inclined bottom surface 31 is provided with an inlet. The water pipe 4 is provided with a recoil outlet pipe 6 on the side of the reservoir connected to the lower end of the inclined bottom surface 31, and an outlet water collection pipe 7 is provided in the vertical subsurface flow wetland, and the water outlet collection pipe 7 is connected with an outlet pipe 5.

[0025] In this embodiment, a water inlet valve 41 is provided on the water inlet pipe 4, a water outlet valve 51 is provided on the water outlet pipe 5, and a recoil outlet valve 61 is provided on the recoil outlet pipe 6, all of which can be switched independently. The lowest point of...

Embodiment 2

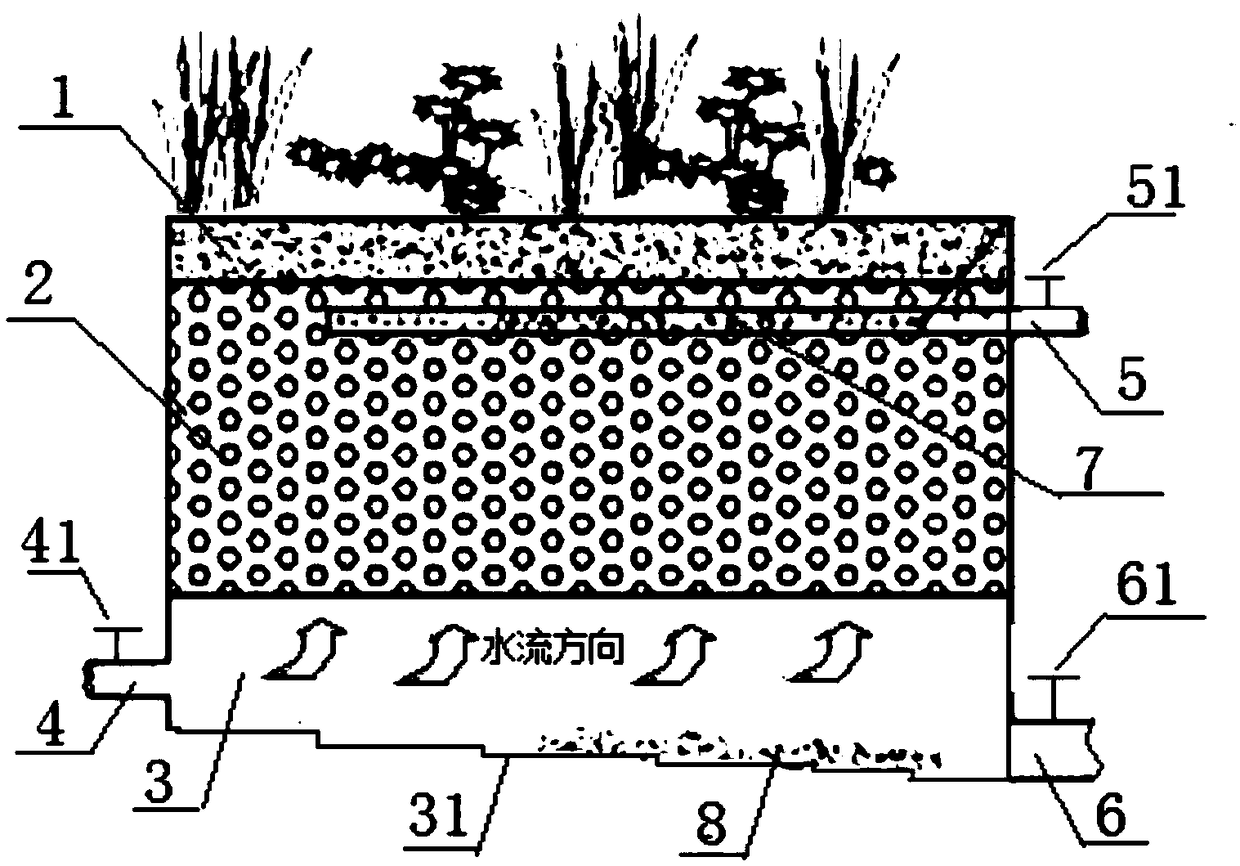

[0029] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the inclined bottom surface 31 is a stepped inclined bottom surface, such as figure 2 shown. The design of the stepped and inclined bottom surface avoids the accumulation of deposited solid impurities in the backwash water pipe during the sewage treatment process, thereby causing blockage of the backwash water pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com