Concrete block curtain wall and manufacture and installation method thereof

A technology of concrete blocks and concrete, which is applied in the direction of walls, building structures, building components, etc., can solve the problems of difficult design and construction, high installation precision, and difficult construction, so as to solve dry hanging, ensure construction quality, meet Effect of Safety Performance Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

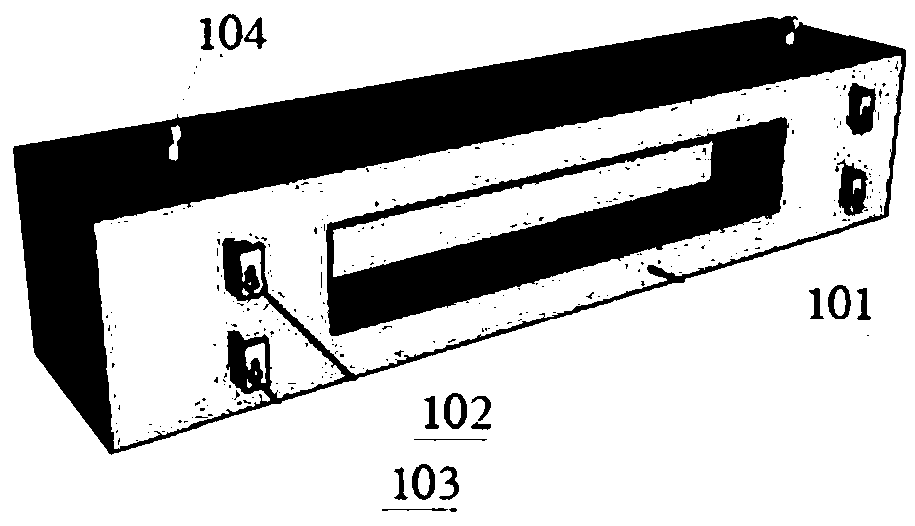

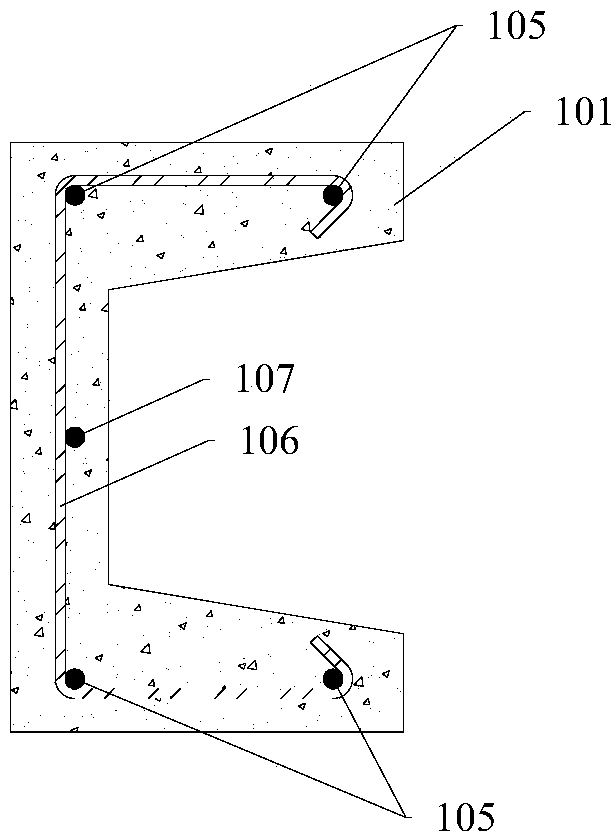

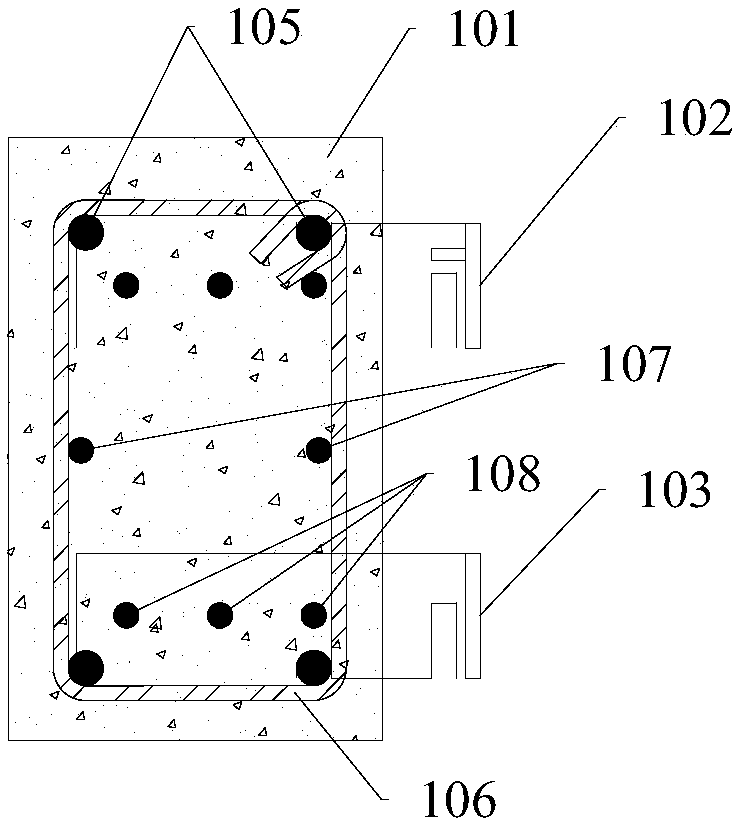

[0051] In this embodiment, the large surface of the engineering curtain wall is made of concrete blocks, and the concrete curtain wall blocks 1 are dry-hanged on the wall through the embedded system to form a curtain wall. The size of the concrete block is mostly 3000*240*150mm, 2000*240*150mm, the largest component is 3000*670*240mm at the top of the top, and the smallest component is the corner component (245+245)*240*150mm, when the block is installed It adopts dry hanging form and misplaced installation. For this reason, in this embodiment, both the concrete curtain wall block 1 and the embedded parts system are optimally designed.

[0052] In this example, if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com