Outline camera, superlarge-diameter rotary workpiece noncontact diameter measuring instrument and noncontact rotary workpieece measuring method

A camera and profile technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of large measurement errors, measurement speed reduction, etc., and achieve high precision, good effect, and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

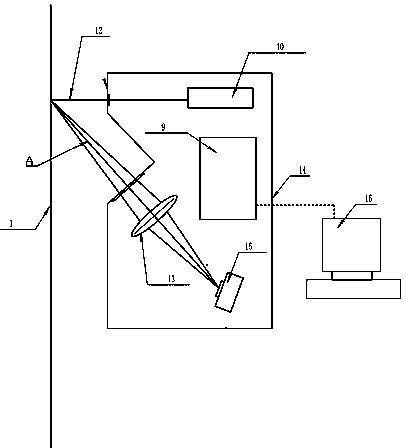

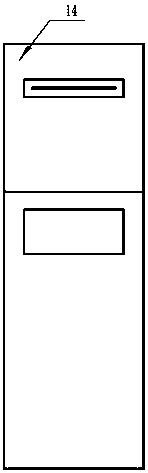

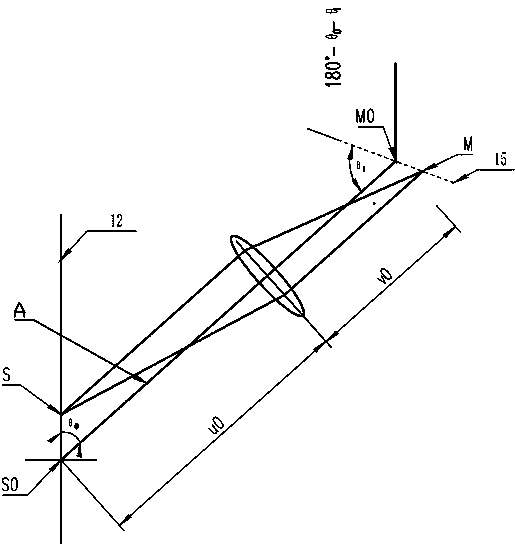

[0049] A profile camera, see Figure 1 to Figure 11 , the profile camera includes a parallel light source generator 10 installed in the housing, a profile camera mounted on the housing and a control processor for photoelectric signal conversion, the profile camera includes an imaging lens group 13 installed on the housing 14, an image Sensor 15, the input end of the control processor is connected to the image sensor 15, and its output end is connected to the image processor and the display to realize data processing and display of the surface profile of the workpiece to be measured; Intersect to form high-brightness arcs, so that the arcs pass through the imaging lens group and focus on the rectangular photosensitive surface of the image sensor to form a real image. The rectangular photosensitive surface of the image sensor is provided with a center line as a measurement reference line. circuit connection.

[0050] The optical axis of the imaging lens group is the A line, the...

Embodiment 2

[0075] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that the contour camera and its measurement method can be applied to the field of side measurement of lathe parts. The parallel light source is projected onto the cylindrical surface of the workpiece, and the contour camera measures the workpiece Whether the outer diameter of the workpiece is qualified.

Embodiment 3

[0076] Embodiment 3: The principle of this embodiment is the same as that of Embodiment 1, except that the specific difference lies in that the workpiece to be measured does not move while the measuring frame moves during measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com