A double-coil charging coil and its manufacturing method

A technology for charging coils and manufacturing methods, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., and can solve problems such as large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Attached below Figures 1 to 12 The present invention is described in further detail.

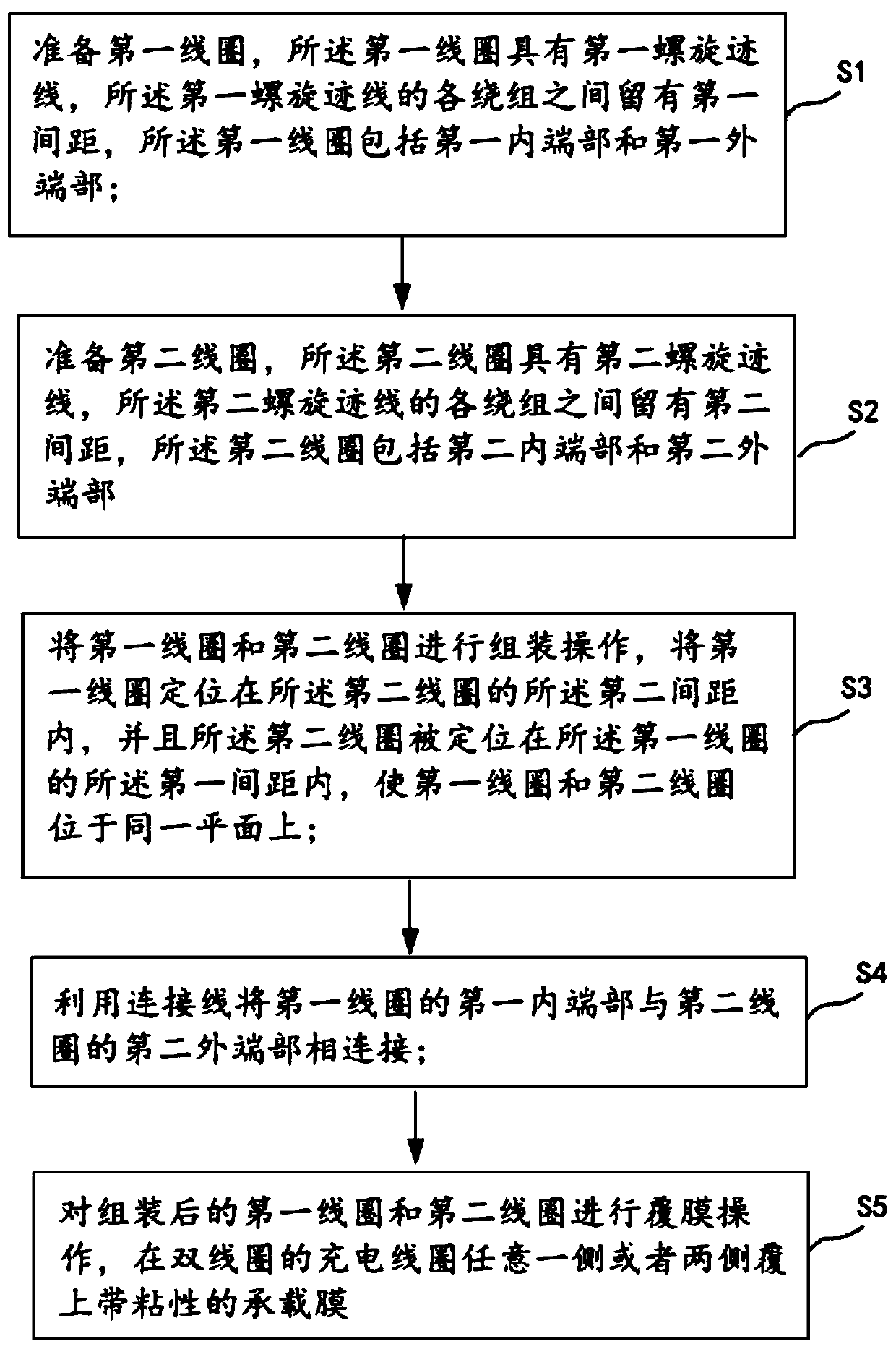

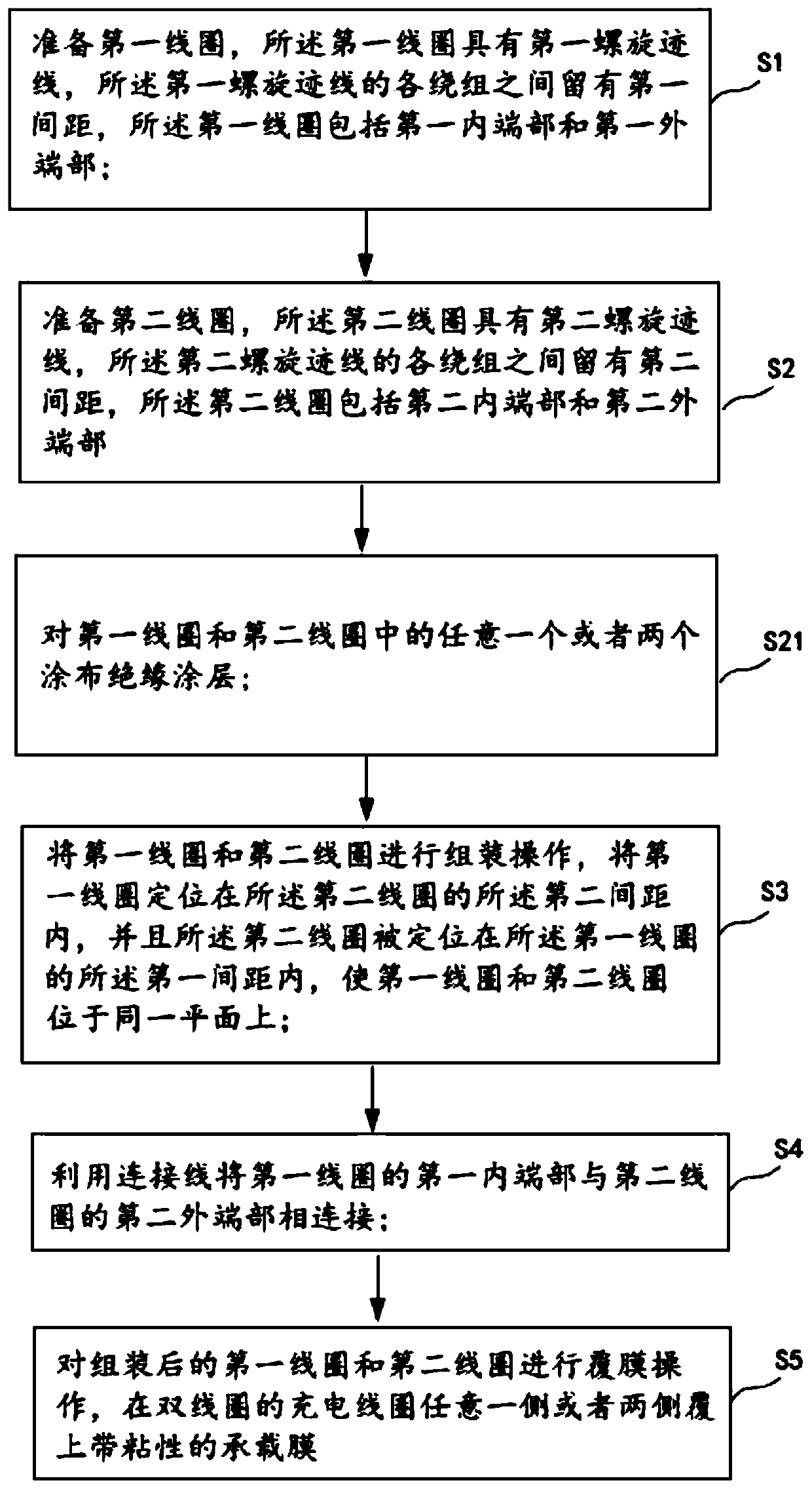

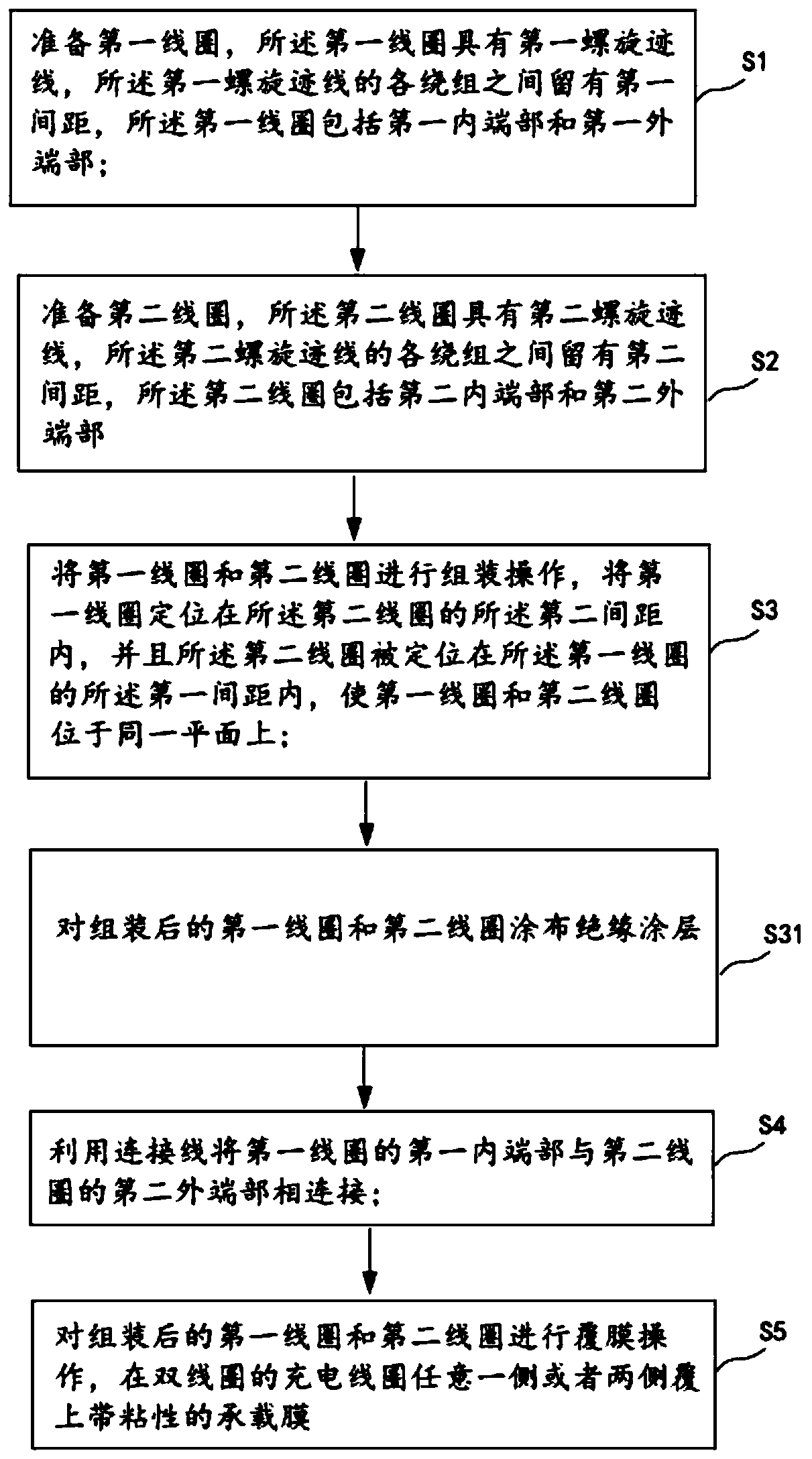

[0055] According to one aspect of the present invention, a method for manufacturing a double-coil charging coil is provided, such as figure 1 As shown, it includes the following steps;

[0056] Step S1: Prepare a first coil 1, the first coil 1 has a first helical trace 2, a first spacing 3 is left between the windings of the first helical trace 2, the first coil 1 comprises a first inner end 4 and the first outer end portion 5;

[0057] Step S2: Prepare the second coil 6, the second coil 6 has a second helical trace 7, a second spacing 8 is left between the windings of the second helical trace 7, the second coil 6 includes a second inner end 9 and the second outer end portion 10;

[0058] Step S3: The first coil 1 and the second coil 6 are assembled, the first coil 1 is positioned within the second interval 8 of the second coil 6 , and the second coil 6 is positioned within the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com