Control method for reducing current fluctuation of switched reluctance motor in current chopping control mode

A switched reluctance motor, current chopping technology, applied in the direction of AC motor control, control system, general control strategy, etc., to achieve the effect of strong versatility, improving rapidity and accuracy, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

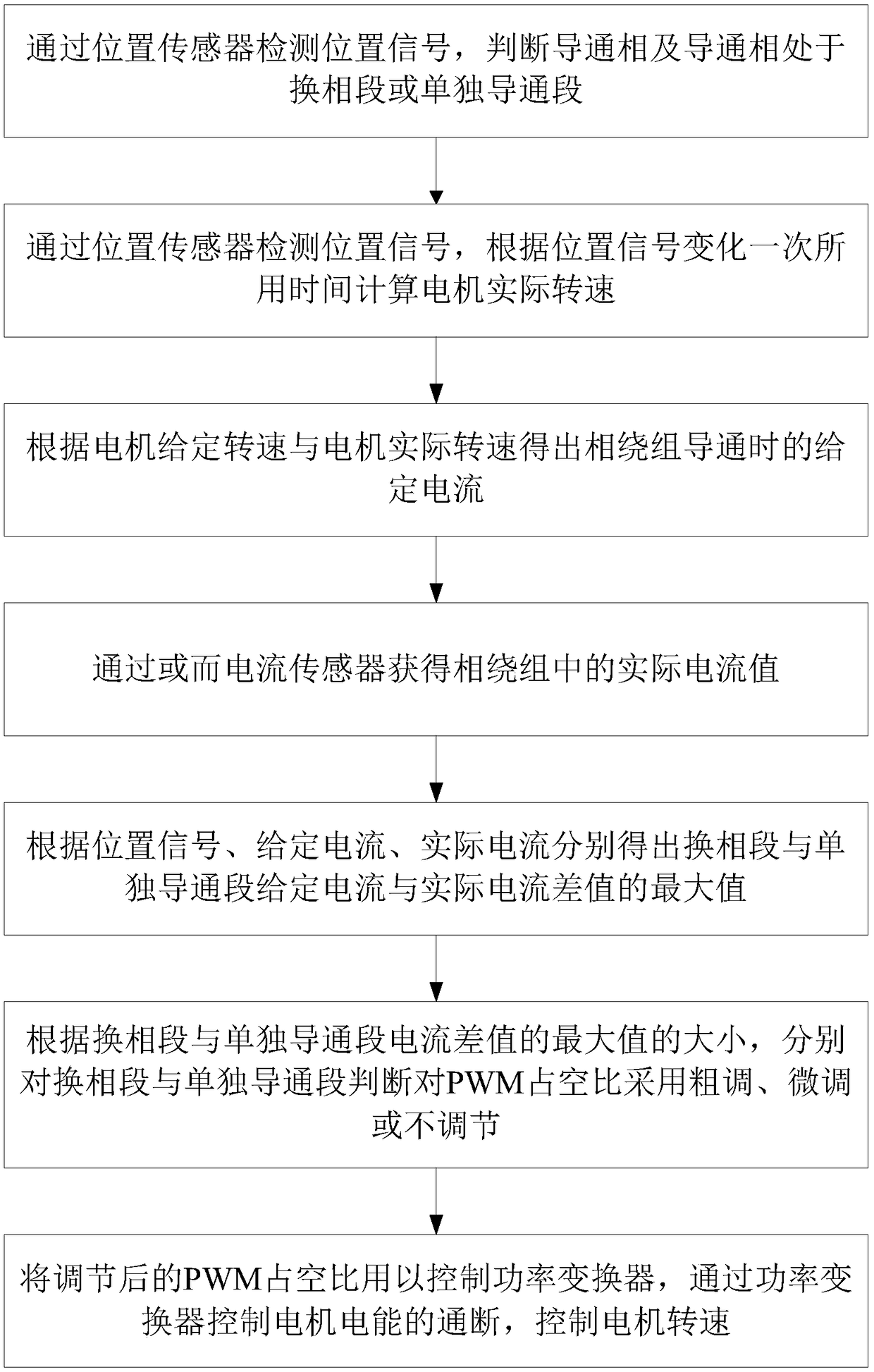

[0048] Step 1: Detect the position signal of the rotor of the switched reluctance motor through the position sensor, distinguish the commutation section and the separate conduction section according to the position signal, and calculate the actual speed of the motor by the time it takes to rotate through a fixed angle;

[0049] Step 2, setting the reference current according to the difference between the actual speed of the motor and the target speed;

[0050] Step 3, collect the actual current value of the phase winding through the Hall current sensor;

[0051] Step 4, according to the difference between the actual current of the winding and the given current, determine the PWM duty cycle when the winding is turned on next time.

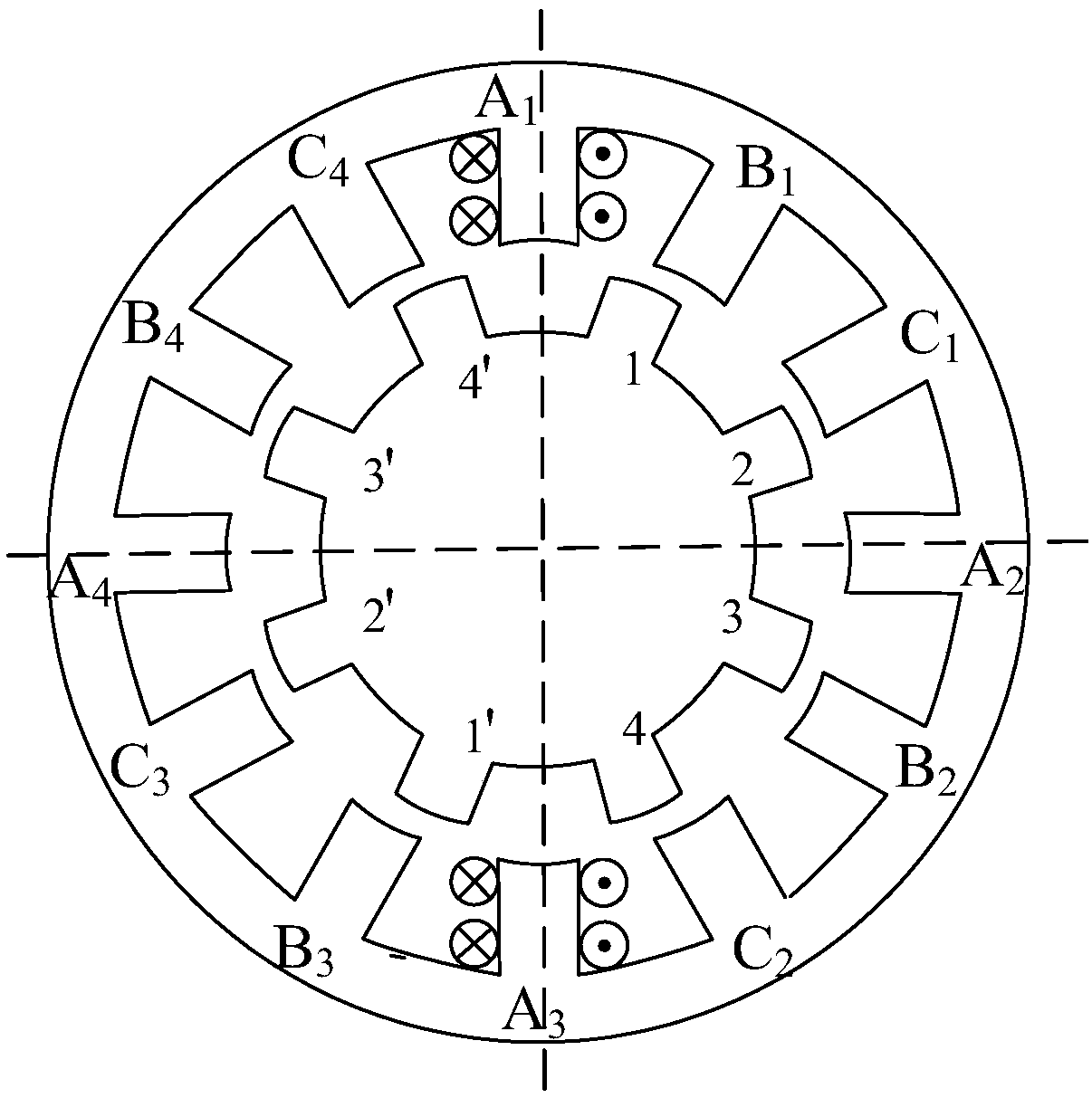

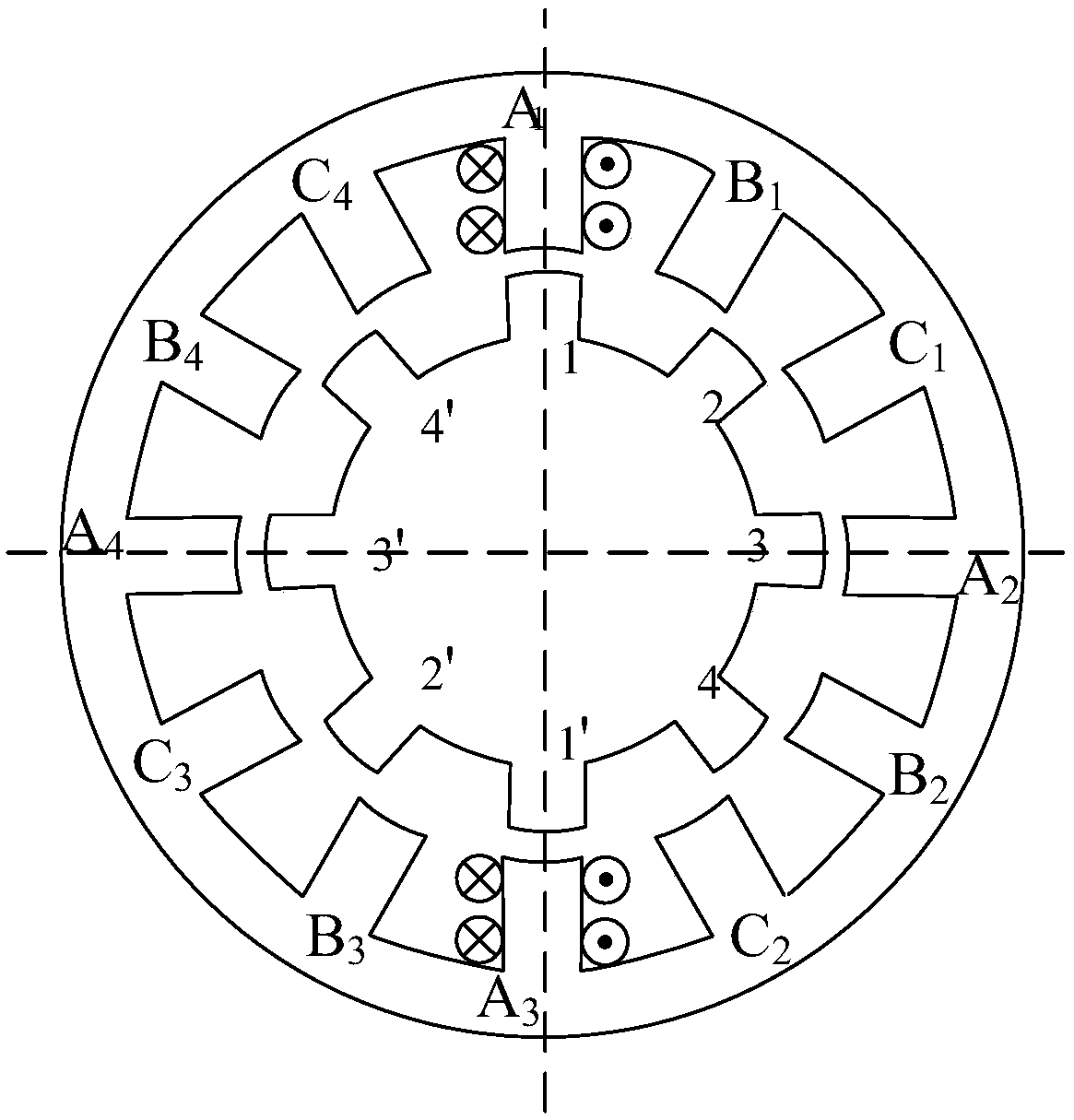

[0052] In step 1 of this embodiment, a three-phase 12 / 8-pole switched reluctance motor is used as a specific embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com