Welding method of steel pipe and joint of steel pipe structure

A welding method and technology for steel pipes, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as improper position relationship between steel pipes and joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

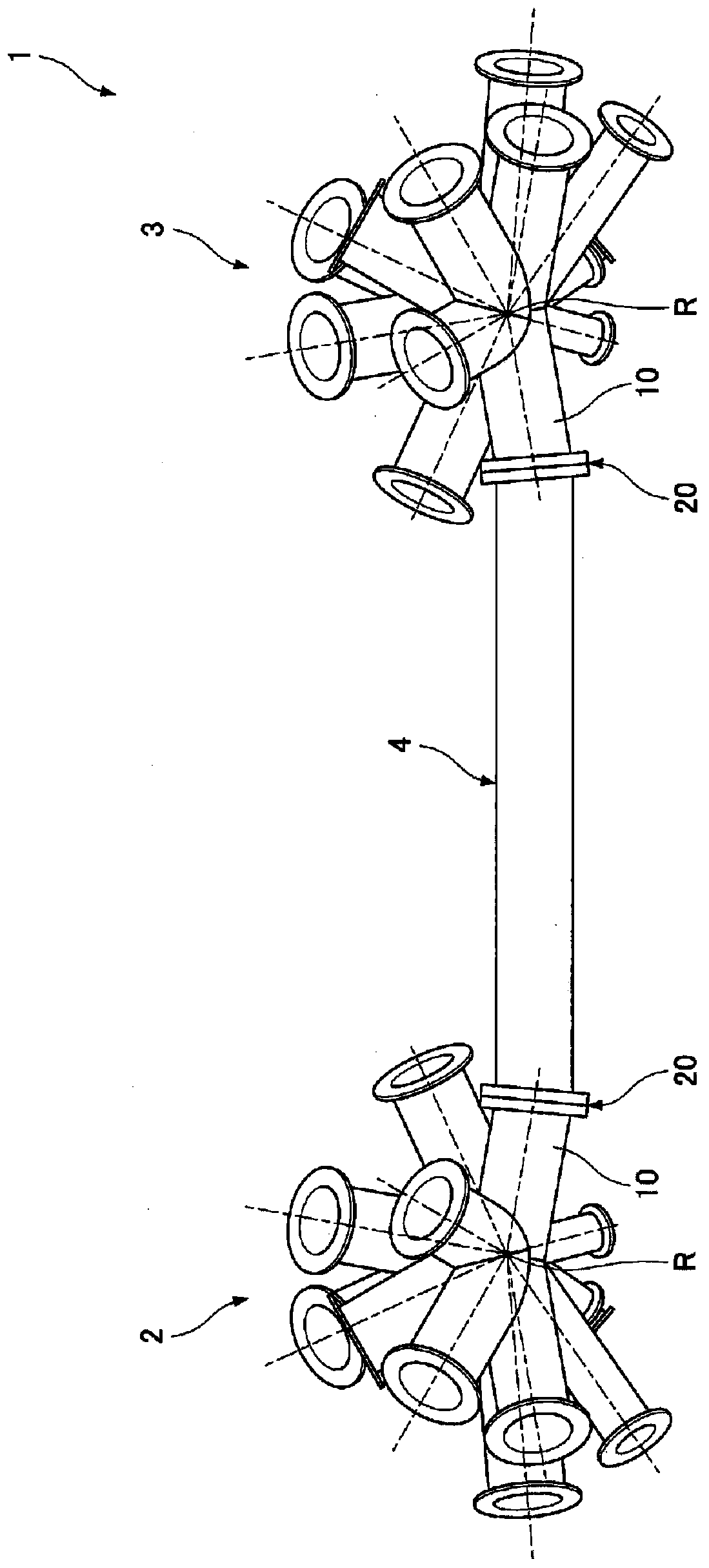

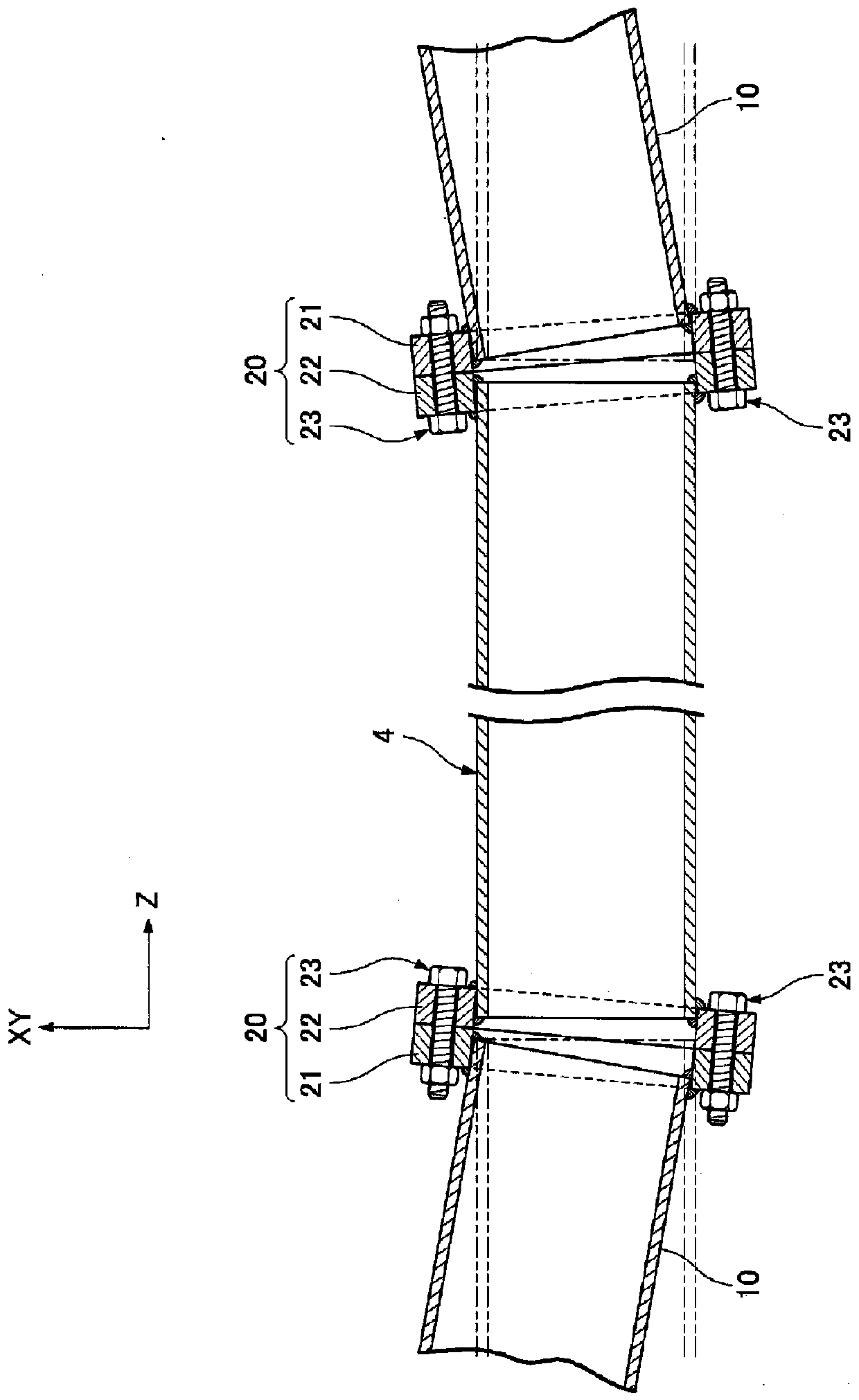

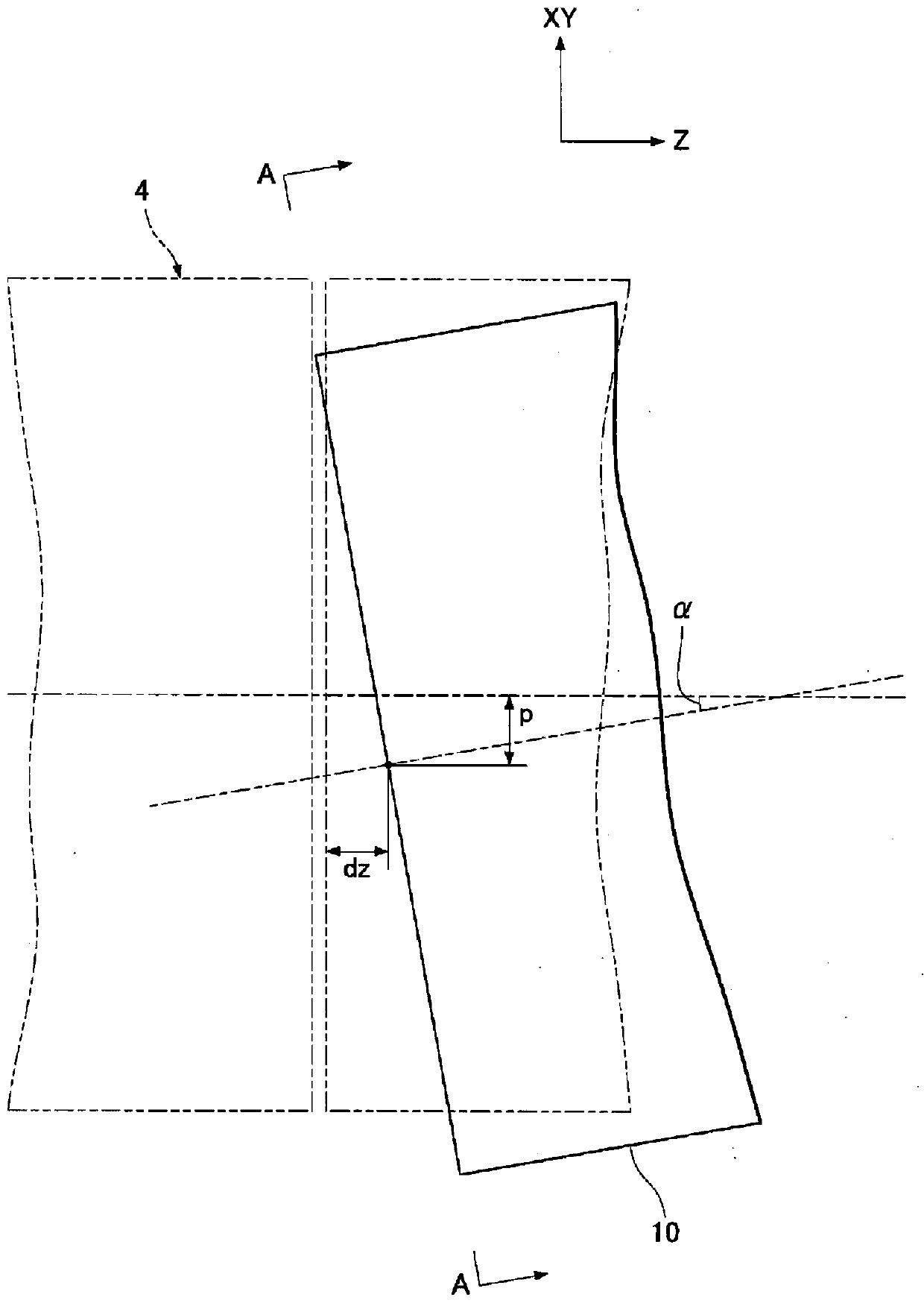

[0020] Hereinafter, the method of welding the steel pipe and the joint of the steel pipe structure according to the embodiment of the present invention will be described. Such as figure 1 As shown, the purpose of welding the steel pipes and joints of the steel pipe structure is to manufacture the connected steel pipe structure 1, and the connected steel pipe structure 1 is made by combining multiple ( figure 1 Two steel pipe structures 2 and 3 are formed by connecting steel pipe structures 2 and 3 different from these steel pipe structures 2 and 3 (hereinafter referred to as steel pipes 4 for connection).

[0021] First, the outline of the above-mentioned connected steel pipe structure 1 will be described with reference to the drawings.

[0022] Such as figure 1 As shown, the connecting steel pipe structure 1 has: a plurality of ( figure 1 As an example, two) steel pipe structures 2, 3; a connecting steel pipe 4 connecting these steel pipe structures 2, 3;

[0023] The abo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap