Full-automatic assembling system of LED glass modulator tubes

A technology of LED glass and assembly system, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc. It can solve the problems of less automated assembly systems, fragility, and short service life, so as to improve positioning accuracy and assembly accuracy, and replace The tooling is simple and easy, and the effect of reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

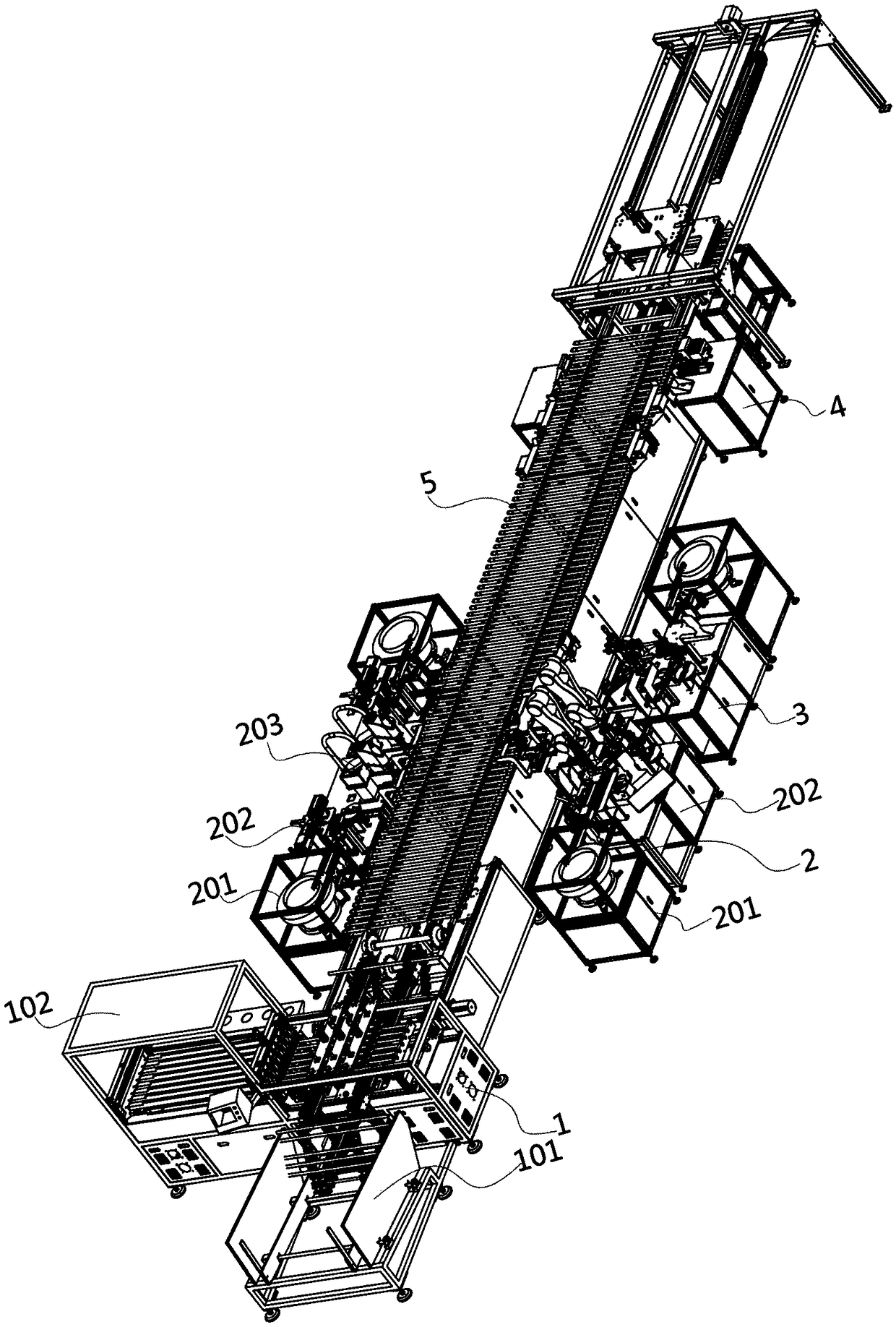

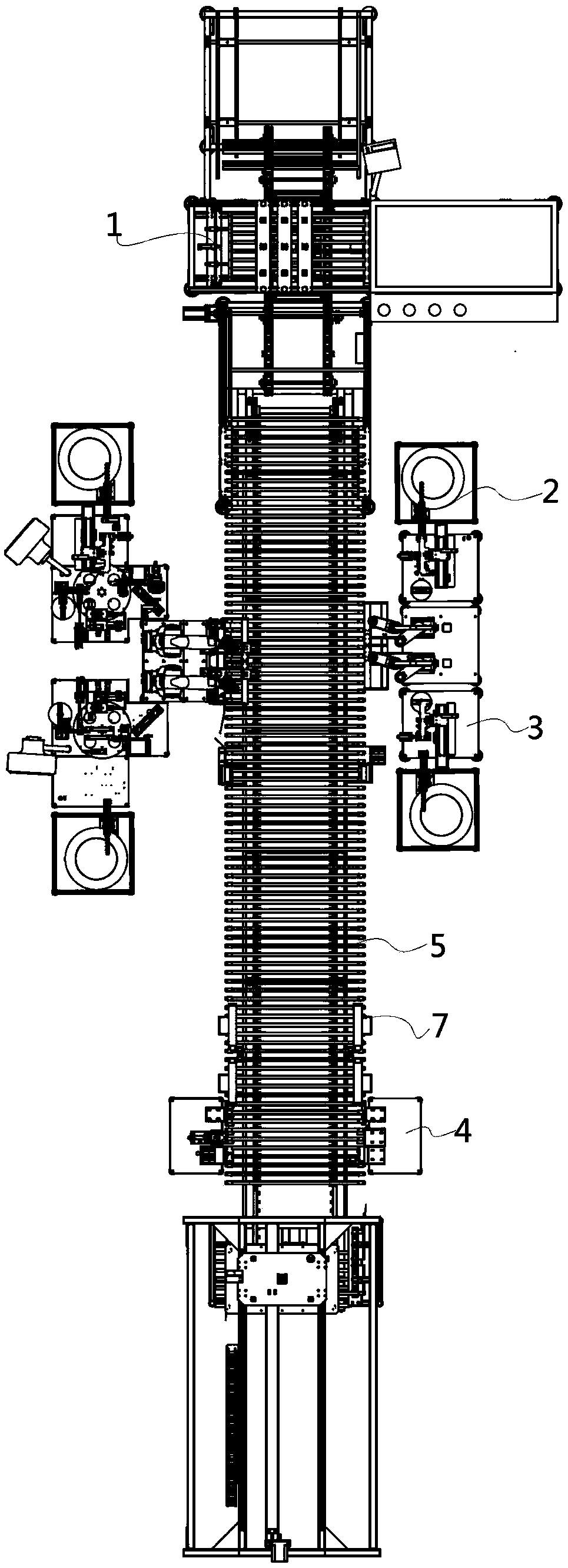

[0022] Such as Figure 1-8 As shown, the specific embodiment of the present invention is a fully automatic assembly system for LED glass lamp tubes, including a feeding module 1, a lamp cap assembly module 2, a power board assembly module 3, and a testing module 4. The feeding module 1 includes a lamp tube feeding mechanism 101 and a light strip pushing mechanism 102; the feeding module 1 is provided with a transportation module 5, and the two sides of the transportation module 5 are sequentially provided with a lamp head assembly module 2, a power board assembly module 3 and Test Module 4;

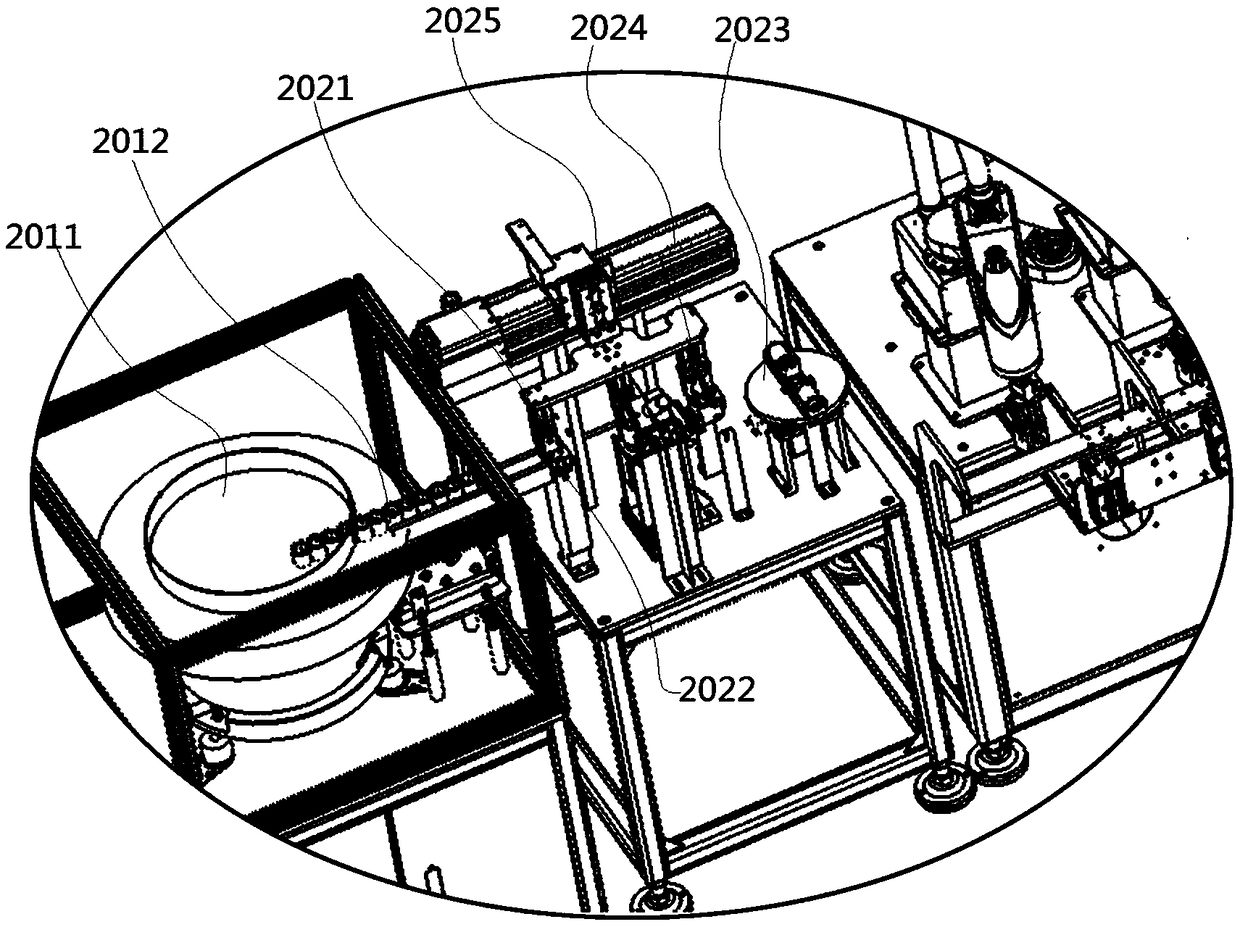

[0023] The lamp cap assembly module 2 includes a lamp cap feeding mechanism 201, a lamp cap conveying mechanism 202, and a lamp cap manipulator assembly mechanism 203. The power board assembly module 3 includes a turntable 301, a power board fee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap