A kind of controllable grouting fluid for coal mining and tunnel engineering and preparation method thereof

A technology for tunnel engineering and coal mines, applied in the field of controllable grouting fluid for coal mining and tunnel engineering and its preparation, can solve the problems of poor fluidity, poor pumpability, polluted groundwater environment, unfavorable plugging of cracks, etc., and achieves later strength No shrinkage, high working efficiency, saving construction time and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

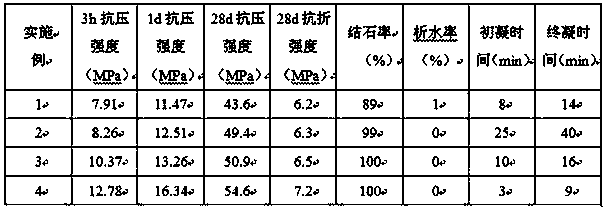

Embodiment 1

[0021] Embodiment 1: A controllable grouting fluid for coal mining and tunnel engineering, made of the following raw materials: 100kg of superfine sulfate cement, 0.5kg of nano silicon dioxide, 6kg of calcined gypsum, 6kg of alum stone powder, lithium carbonate 0.05kg, wood calcium 0.3kg and water 80kg.

[0022] The method for preparing the controllable grouting fluid for a kind of coal mining and tunnel engineering, the steps are as follows:

[0023] (1) Add water to superfine sulfate cement to make a slurry with a water-cement ratio of 0.8 for later use;

[0024] (2) Add nano-silica, calcined gypsum and alunite powder into the slurry in step (1) and stir until completely dissolved;

[0025] (3) Add lithium carbonate and wood calcium into the mixture in step (2) and stir until completely dissolved.

Embodiment 2

[0026] Embodiment 2: A controllable grouting fluid for coal mining and tunnel engineering, made of the following raw materials: 100kg of superfine sulfate cement, 3kg of redispersible latex powder, 0.4kg of high-efficiency water reducer FDN, nanometer two Silicon oxide 0.5kg, calcined gypsum 6kg, alum stone powder 6kg, lithium carbonate 0.05kg, wood calcium 0.3kg and water 80kg.

[0027] The method for preparing the controllable grouting fluid for a kind of coal mining and tunnel engineering, the steps are as follows:

[0028] (1) Add water to superfine sulfate cement to make a slurry with a water-cement ratio of 0.8 for later use;

[0029] (2) Add dispersible latex powder, high-efficiency water reducer FDN, nano-silica, calcined gypsum and alunite powder into the slurry in step (1) and stir until completely dissolved;

[0030] (3) Add lithium carbonate and wood calcium into the mixture in step (2) and stir until completely dissolved.

Embodiment 3

[0031] Embodiment 3: A controllable grouting fluid for coal mining and tunnel engineering, made of the following raw materials: 100kg of superfine sulfate cement, 3kg of redispersible latex powder, 0.4kg of high-efficiency water reducer FDN, nanometer two Silicon oxide 0.5kg, calcined gypsum 7kg, alum stone powder 7kg, lithium carbonate 0.05kg, wood calcium 0.3kg and water 80kg. The preparation method is the same as the preparation method described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com