Self-walking surface mining machine with multiple cutting heads

An open-pit mining machine and cutting head technology, which is applied in cutting machinery, open-pit mining, special mining, etc., can solve the problems of narrow application range of mining equipment, high procurement and management costs, and uneconomical mining. The effect of low procurement and management costs, high production efficiency, and continuous external delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

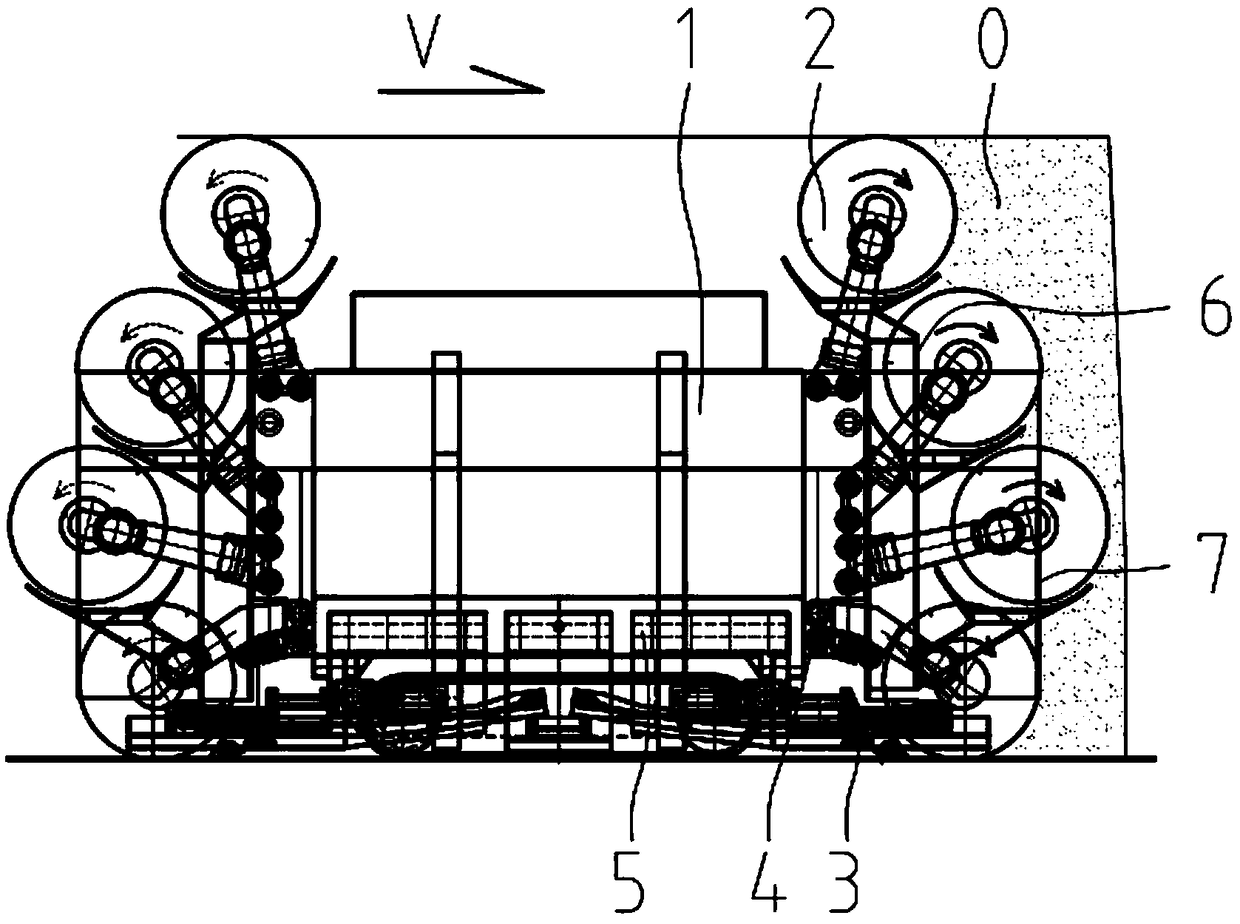

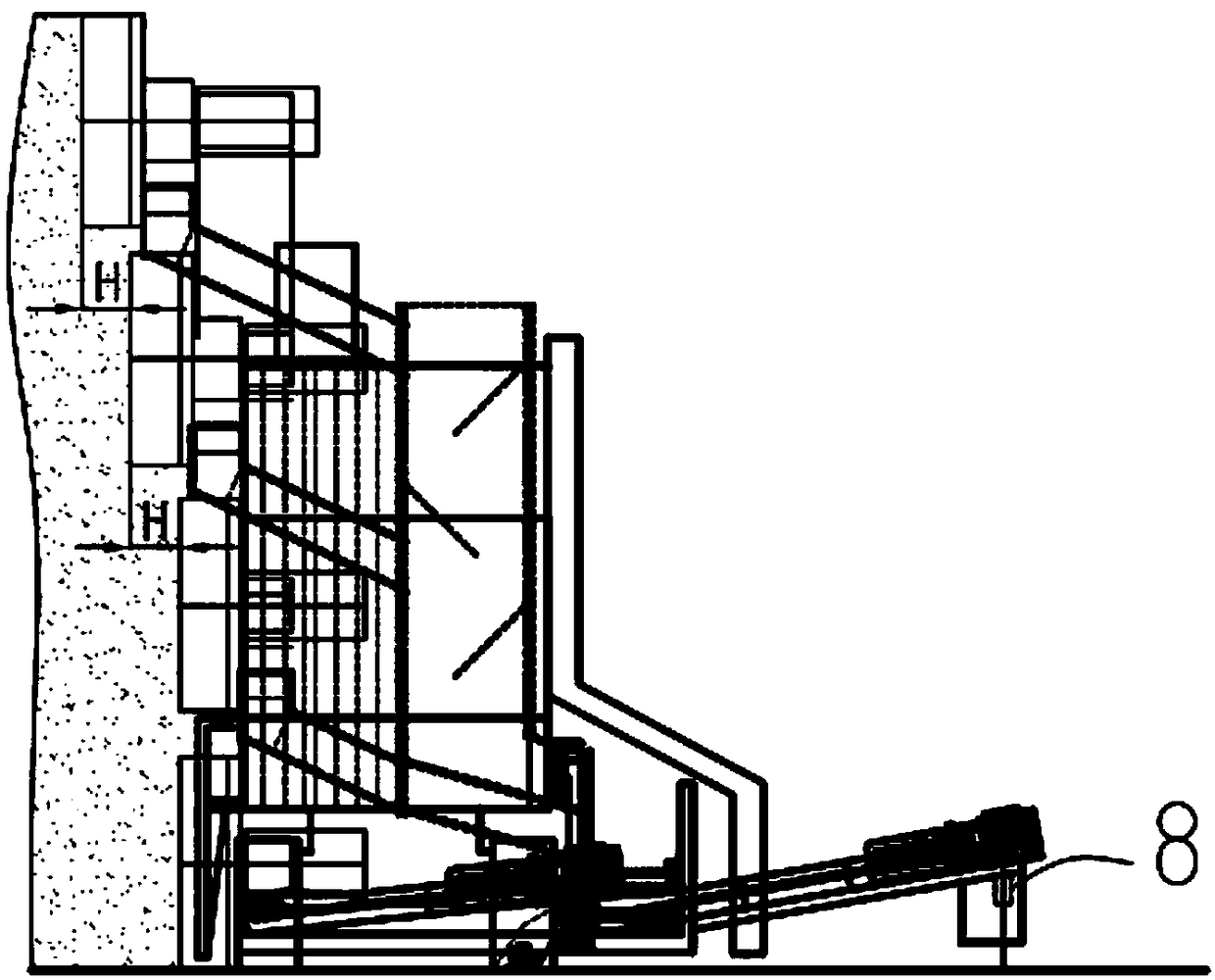

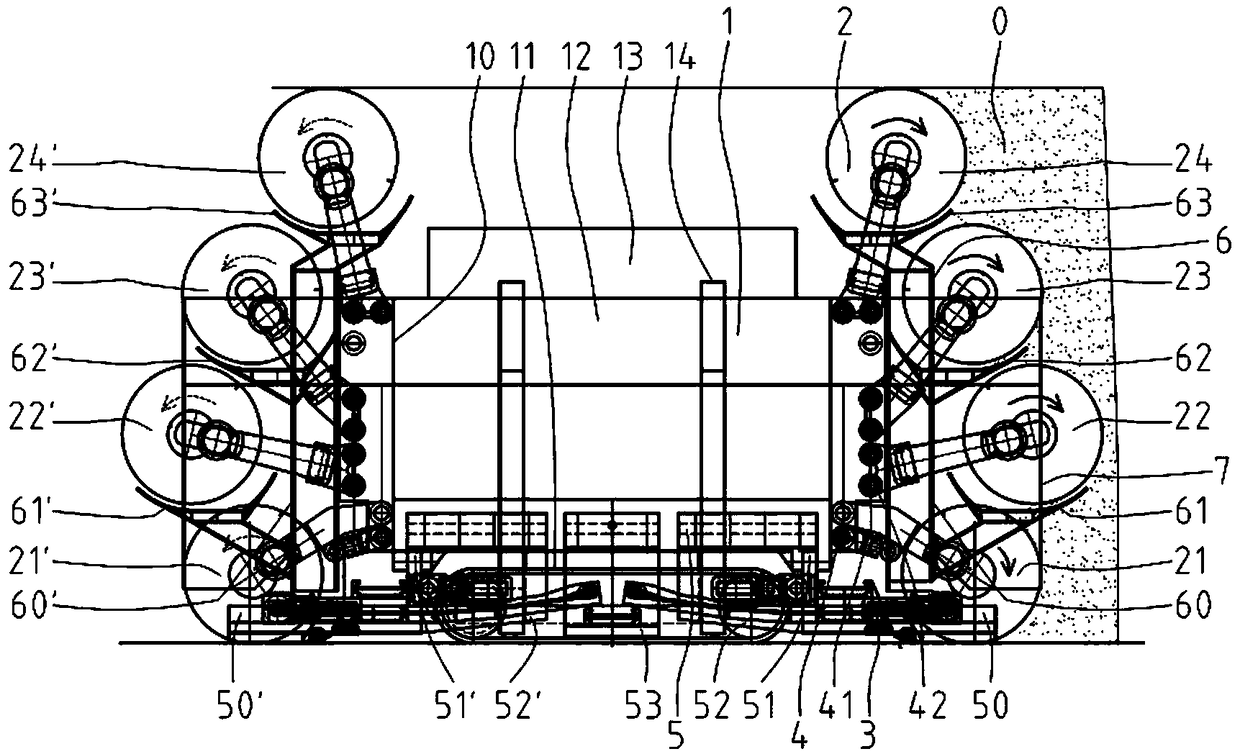

[0077] Such as Figure 1a-5 As shown, the cutting head group has four cutting heads. The cutting head group on the right side comprises the first right cutting head 21, the second right cutting head 22, the third right cutting head 23, and the right four cutting heads 24. The cutting head group on the left side comprises left one cutting head 21 ', left two cutting heads 22 ', left three cutting heads 23 ', left four cutting heads 24'.

[0078] The first cutting head on the right, the second cutting head on the right, the third cutting head on the right and the fourth cutting head on the right are located at the right side of the fuselage near the mine wall and are arranged from bottom to top. The second cutting head, the third left cutting head, and the fourth left cutting head are located at the left end of the fuselage near the mine wall, and are arranged from bottom to top.

[0079] The large planes of the drums of the first right cutting head and the second right cuttin...

Embodiment 2

[0084] Such as Figure 6a , 6b As shown, the cutting head group has three cutting heads. The cutting head group on the right side includes the first right cutting head 21, the second right cutting head 22, and the third right cutting head 23. The cutting head group on the left side comprises a left cutting head 21 ', a left second cutting head 22', and a left three cutting head 23'.

[0085] The first cutting head on the right, the second cutting head on the right and the third cutting head on the right are located at the right side of the fuselage near the mine wall and are arranged from bottom to top. The first cutting head on the left, the second cutting head on the left, the left The three cutting heads are located at the left end of the fuselage near the mine wall, and are arranged from bottom to top.

[0086] The large planes of the cylinders of the first right cutting head and the second right cutting head are flush, and the large plane of the drum of the third right...

Embodiment 3

[0093] Such as Figure 7a , 7b As shown, the cutting head group has two cutting heads. The cutting head group on the right side comprises a right cutting head 21, the right two cutting heads 22, and the cutting head group on the left side comprises a left cutting head 21 ', a left two cutting head 22'.

[0094] The first right cutting head and the second right cutting head are located at the right end of the fuselage near the mine wall, and are arranged from bottom to top; the first left cutting head and the second left cutting head are located at the left end of the fuselage Near the side of the mine wall and arranged from bottom to top.

[0095] The large planes of the drums of the first right cutting head and the second right cutting head are flush. The large planes of the drums of the first left cutting head and the second left cutting head are flush.

[0096] The right first cutting head and the left first cutting head are connected with the fuselage through the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com