Automatic locking and unlocking mechanism for rotating shaft system type devices

A technology of automatic locking and unlocking mechanism, applied in the direction of brake actuator, mechanical equipment, gear shifting mechanism, etc., can solve the problems of difficult to pull out the bolt, incomplete unlocking, incomplete pulling out, etc., to achieve complete unlocking, weight Light, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

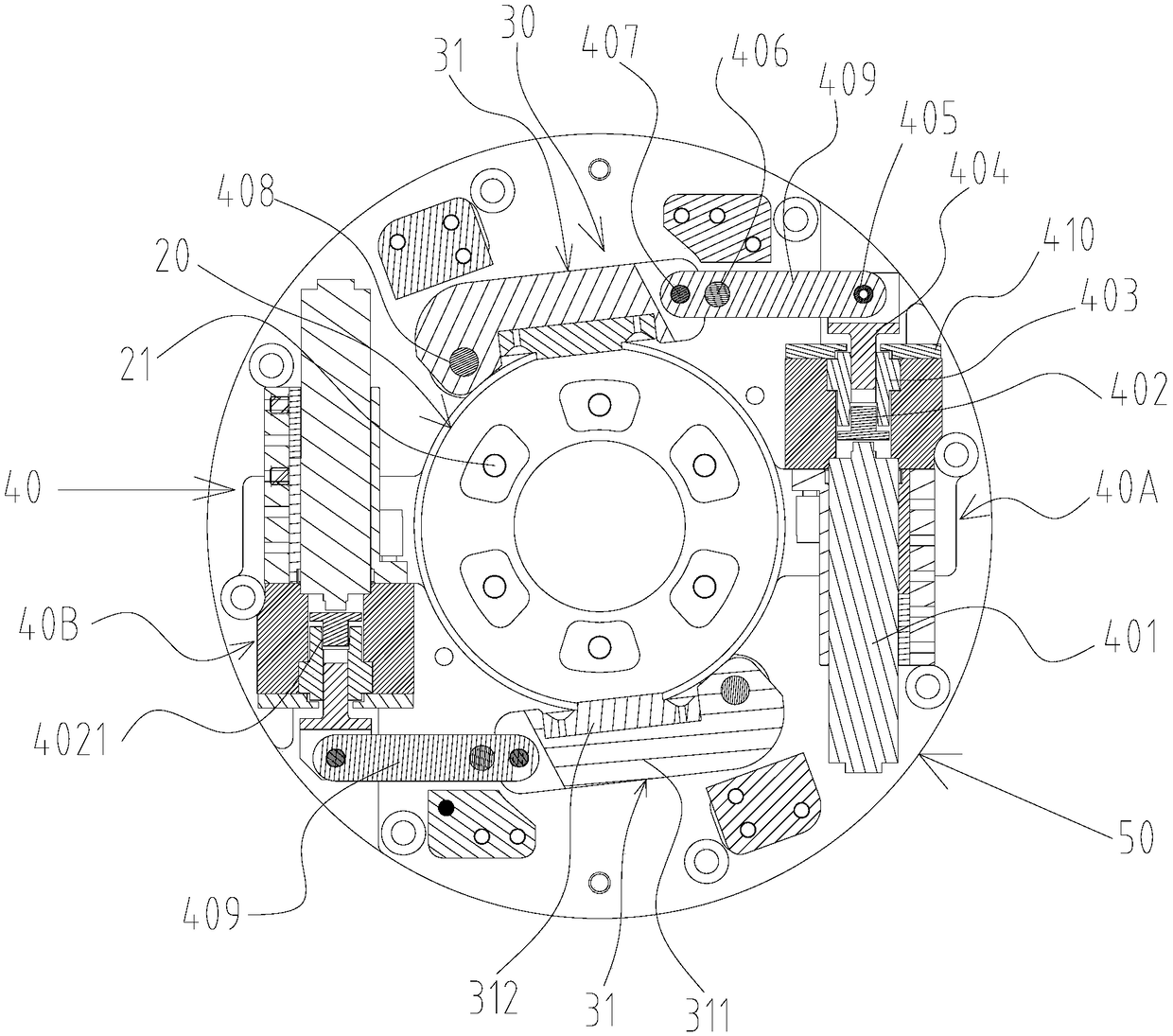

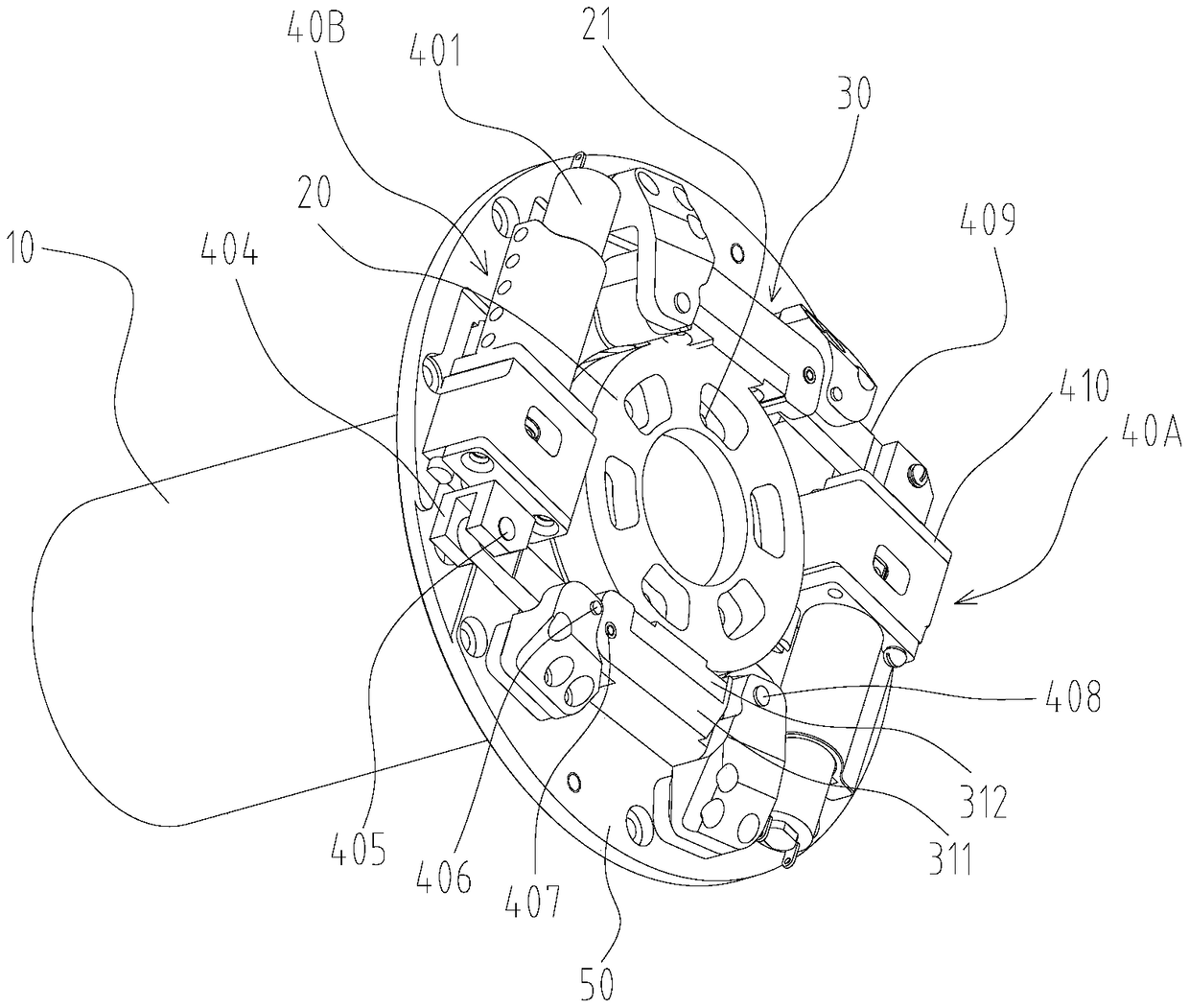

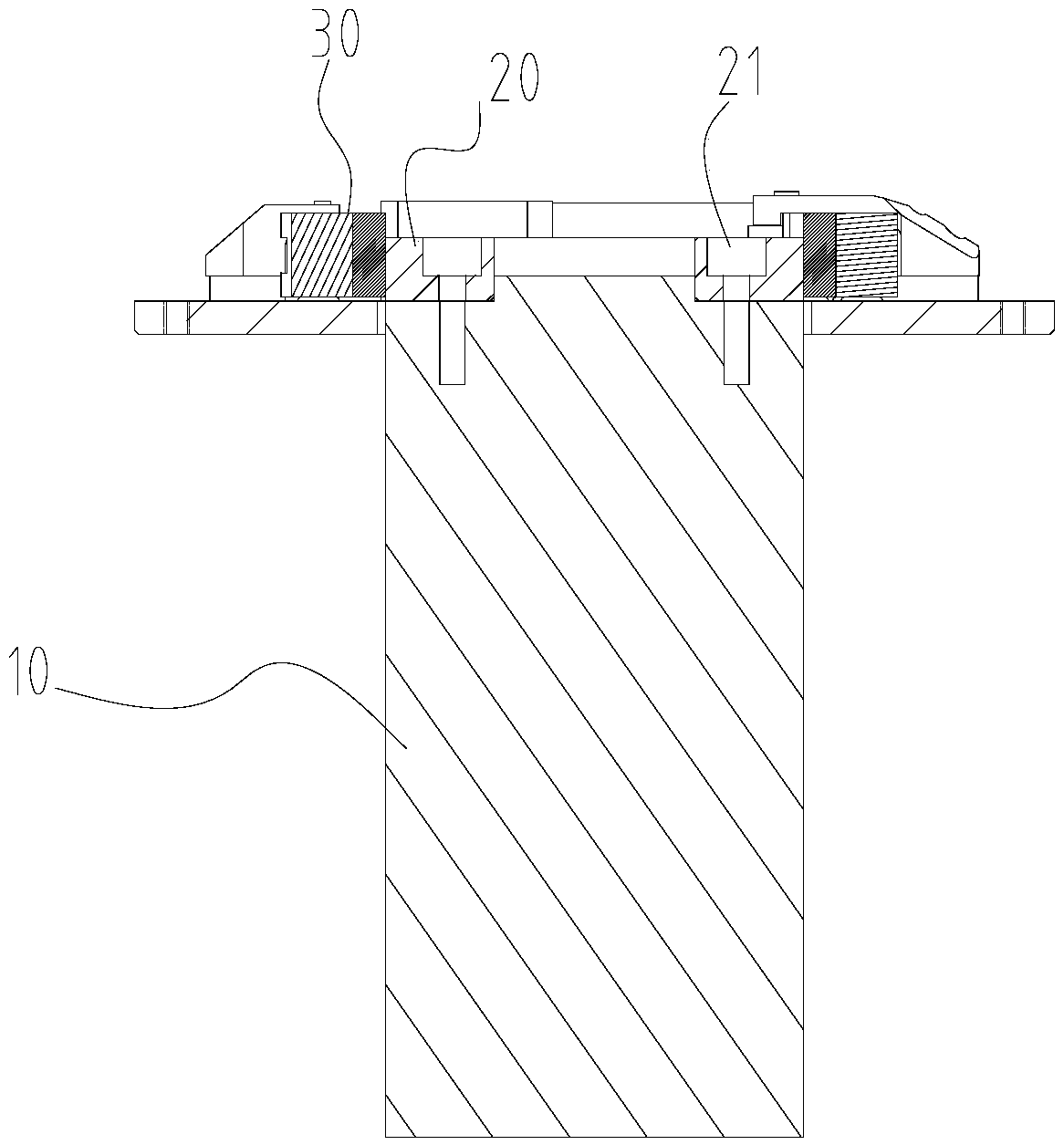

[0023] refer to figure 1 , figure 2 , The automatic locking and unlocking mechanism of the rotating shaft equipment of the present invention includes a rotating shaft 10 , a friction disc 20 , a friction plate assembly 30 , a driving mechanism 40 and a base 50 .

[0024] In the present invention, the rotating shaft 10 is the rotating shaft of some kind of rotating equipment, such as the rotating shaft of the known precision turntable and the rotating strapdown inertial group rotating shaft. In this example, if image 3 One end of the illustrated rotating shaft is connected to the rotating device and the other end is connected to the friction disc 20 . In the present invention, the rotating shaft 10, the friction disc 20, the friction plate assembly 30, and the driving mechanism 40 are all arranged on the base 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com