Crushing system for phosphorus-containing gypsum

A crushing system and gypsum technology, applied in the direction of grain processing, etc., can solve the problems of low production efficiency, low processing efficiency, large material volume, etc., and achieve the effect of easy maintenance, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

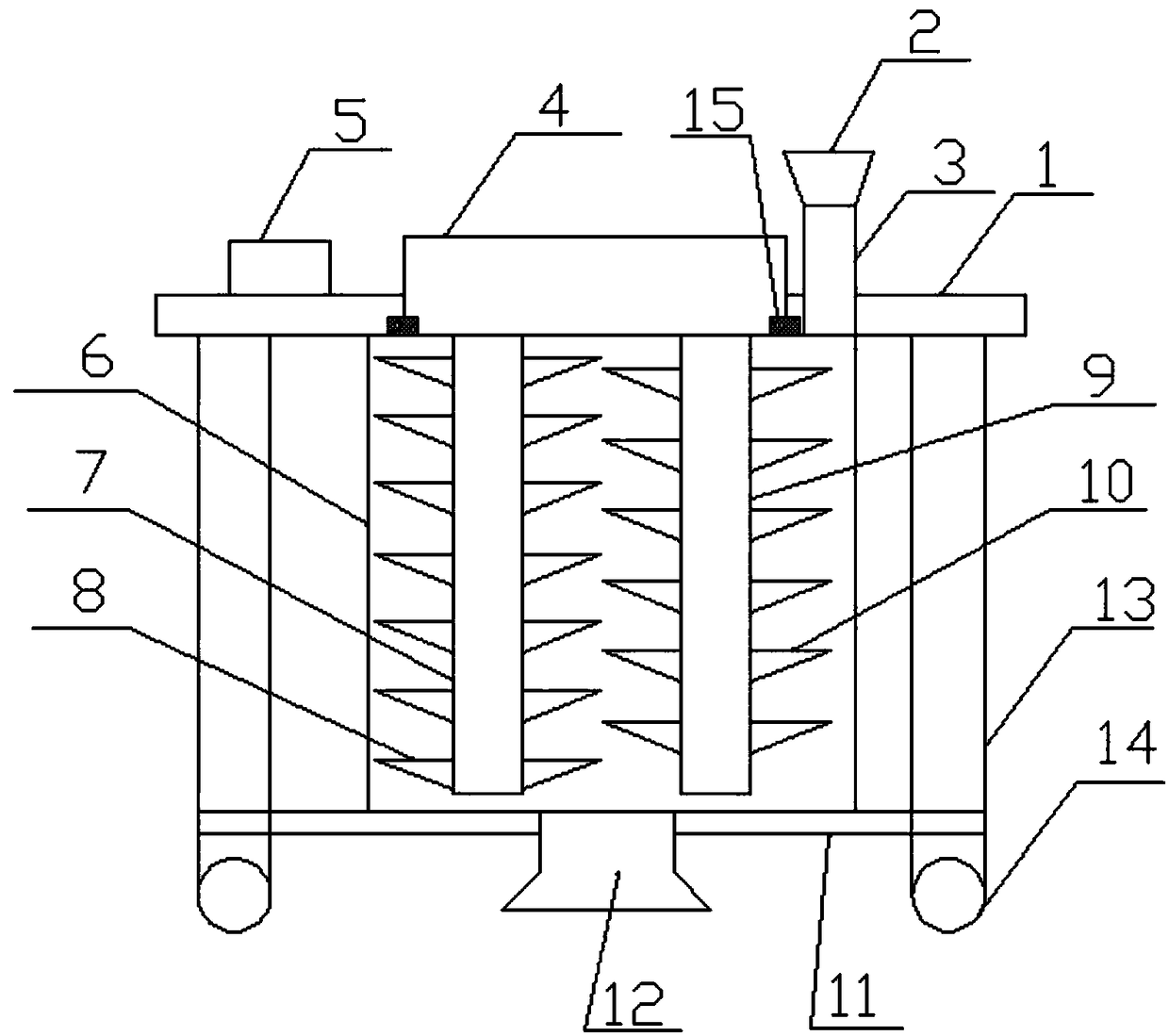

[0019] Such as figure 1 As shown, the present invention provides a phosphorus-containing gypsum crushing system, comprising a working platform 1, one side of the working platform 1 is provided with a discharge port 2, the bottom end of the discharge port 2 is provided with a discharge pipeline 3, and the discharge port 2 A rotating motor 4 is provided on one side of the rotating motor 4, a control panel 5 is provided on one side of the rotating motor 4, a crushing tank 6 is provided at the bottom of the working platform 1, and a first rotating shaft 7 and a second rotating shaft are arranged inside the crushing tank 6 9. The surface of the first rotating shaft 7 is provided with a first blade 8, the surface of the second rotating shaft 9 is provided with a second blade 10, the bottom end of the crushing tank 6 is provided with a horizontal plate 11, and the middle part of the horizontal plate 11 is provided with a Outlet 12.

[0020] Rotary motor 4 is fixedly connected with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com