A coating protection method of variable thickness paint

A technology of variable thickness and coating, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of long production cycle, low production efficiency, tape pollution, etc., and achieve a wide range of implementation and large differences in the appearance of multiple structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

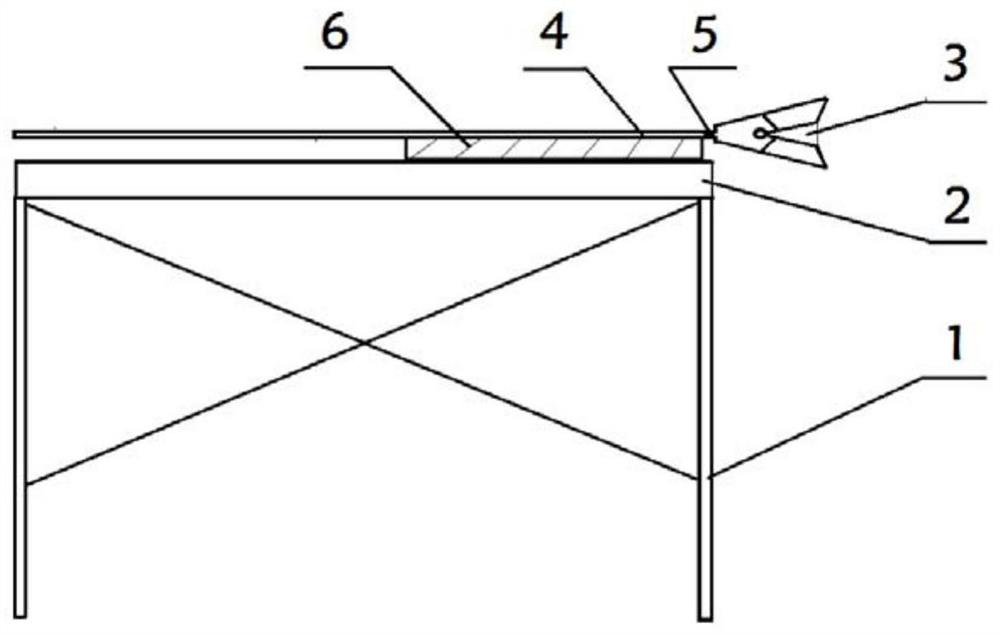

[0017] The specific implementation manners are further described below in conjunction with the accompanying drawings.

[0018] The invention comprises: a bracket 1, a workbench 2, a clip 3, a plastic protective film, and a plastically deformable metal wire 5.

[0019] Before coating is applied:

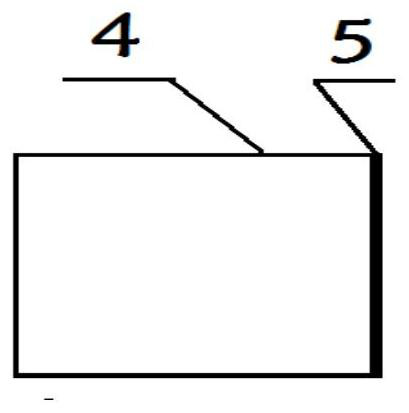

[0020] a) According to the size of the parts to be protected and the size of the workbench, use the existing and plastically deformable metal wire 5, take the plastically deformable metal wire 5 as the axis, wrap the plastic protective film around the axis for about 2 weeks, heat seal and fix it with a hair dryer, and make One side plastically deformable plastic film 4 larger than the size of the workbench;

[0021] b) Place the paint spraying workbench 2 on the support 1 according to the conventional paint coating preparation method;

[0022] c) According to the position of the parts to be protected, place the parts 6 on the workbench 2, and use the clip 3 to assist the plastic fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com