Plasma processing device used for super-smooth surface

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as polishing surface pollution, and achieve the effects of improving the ionization rate, increasing the number of collisions, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

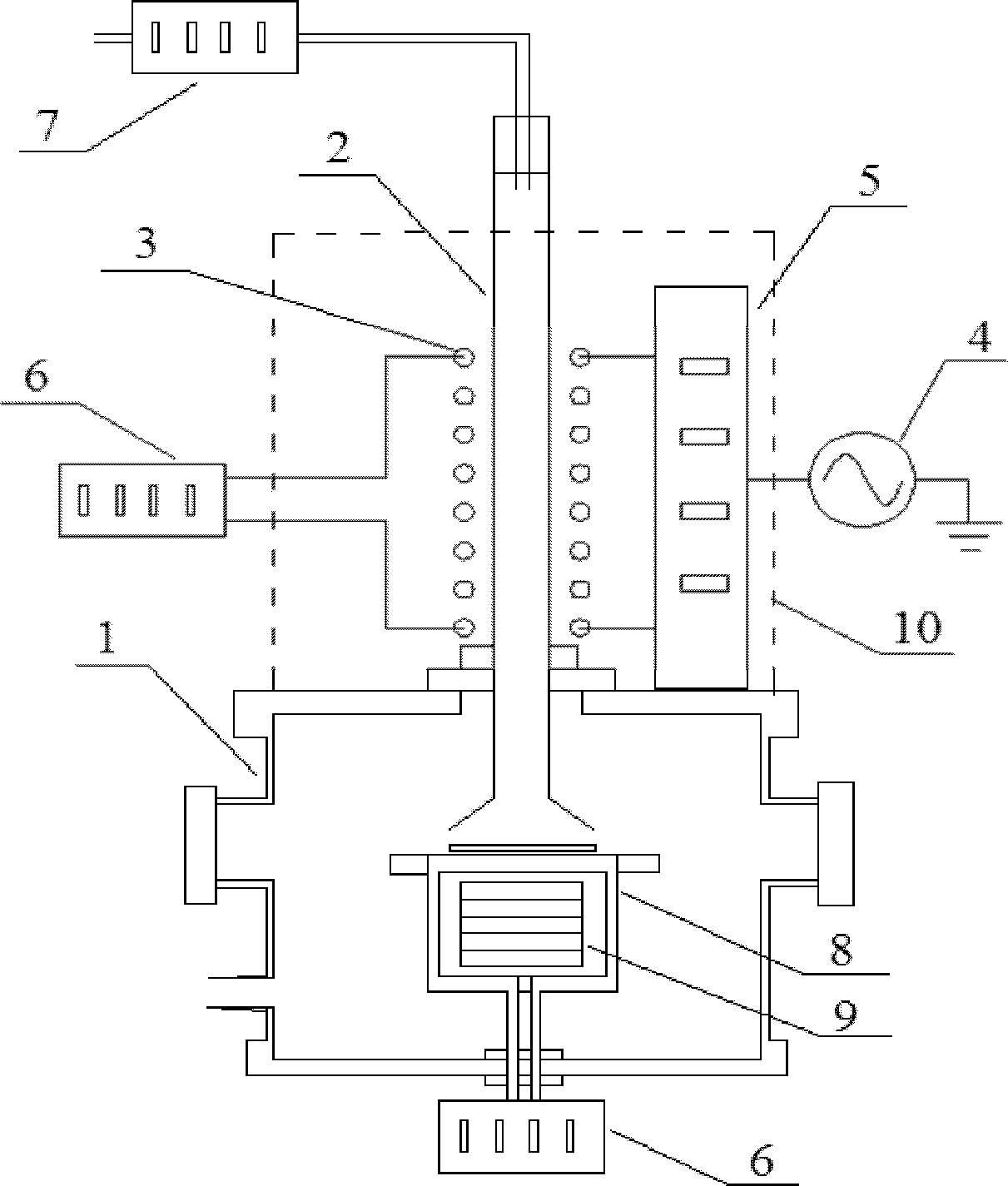

[0024] Please refer to FIG. 1 . FIG. 1 is a schematic structural diagram of a plasma processing device for ultra-smooth surfaces according to the present invention. As shown in the figure, the plasma processing device includes: a vacuum system, an inductively coupled plasma generation system and a water cooling system.

[0025] The vacuum system includes a vacuum chamber 1 and an exhaust unit (not shown in the figure). The vacuum cavity 1 provides a vacuum environment for surface polishing of the price to be processed in the present invention. In order to reduce the contamination of the surface by particles in the air during polishing, the air pressure in the vacuum chamber 1 is required to reach 0.001Pa to 100Pa. Therefore, the designed air extraction unit includes a molecular pump and a mechanical pump. The mechanical pump is used to pre-pump the vacuum chamber 1 first, and then the molecular pump is used for deep pumping until the vacuum chamber reaches the required air pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com