Method of manufacturing ink powder by supercritical fluid dissolving spraying technology

A supercritical fluid and supercritical technology, applied in the field of toner manufacturing, can solve the problems of large heat consumption and less than 5% market share.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

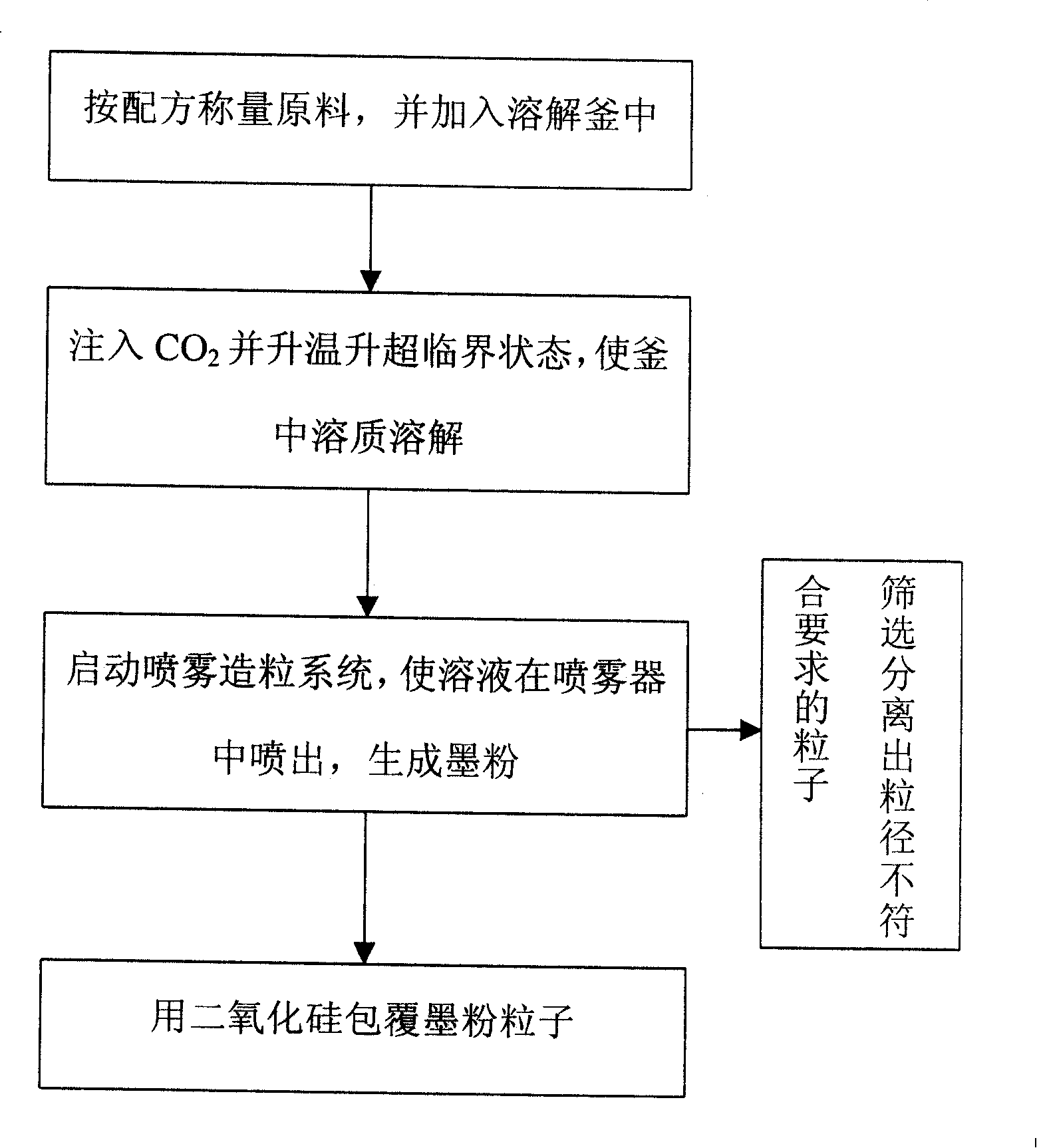

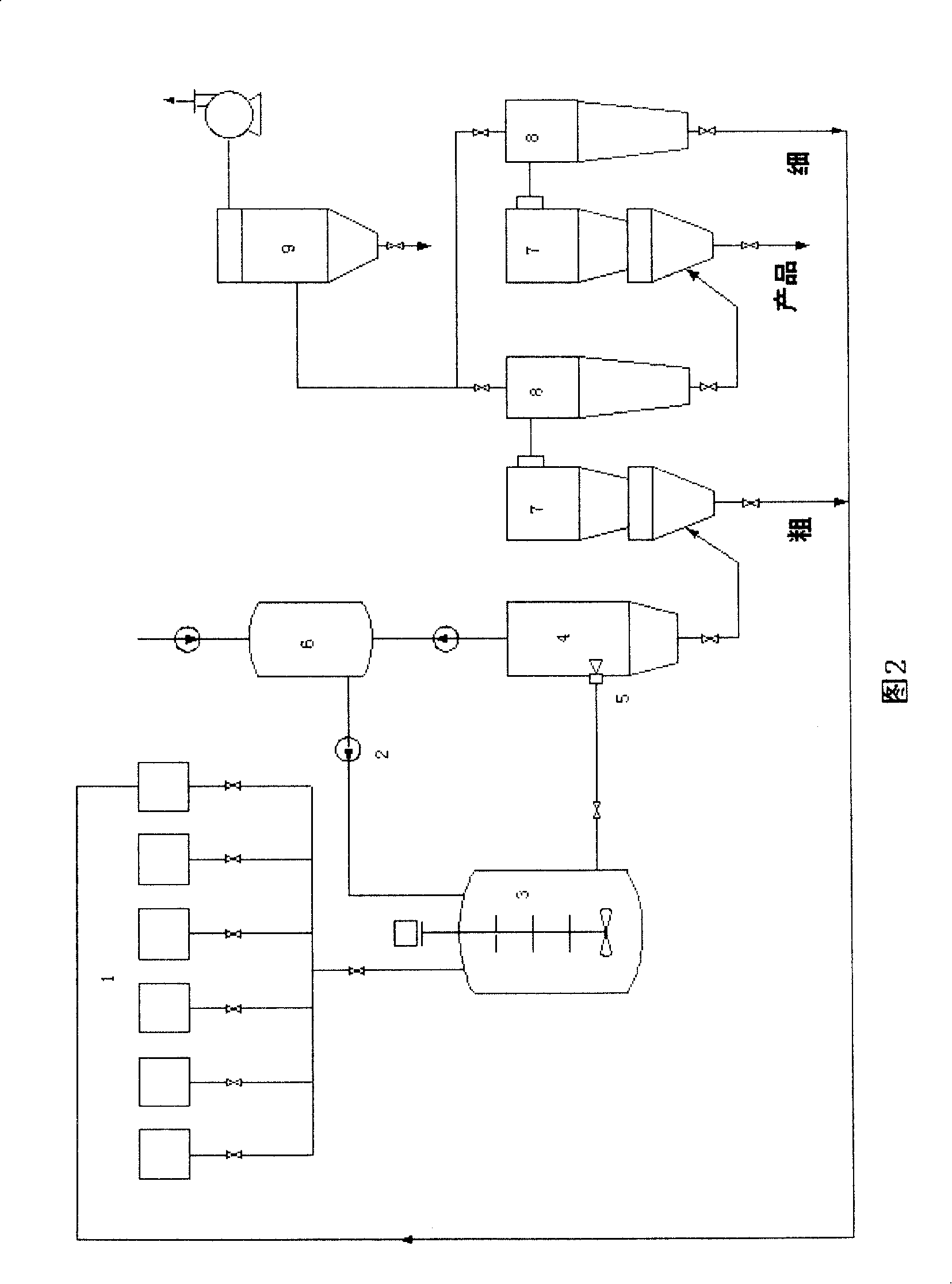

[0020] Such as figure 1 , as shown in Figure 2:

[0021] (A) According to the composition of traditional production toner in the batching system 1, the following mass ratios are used for the single-component insulating black and color toner: 100 parts of hot-melt resin, 5-120 parts of pigment or dye, 2~6 parts of charge control agent and 0~5% of carbon dioxide solvent as the carrier agent are ready for use; if waste black or color toner is used as raw material for recycling, 100 parts of screened and available toner should be used , reheat 0-20 parts of meltable resin, 0-30 parts of pigment or dye, and 0-4 parts of charge control agent for use.

[0022] The above-mentioned prepared material can be added in the dissolving kettle 3 in advance, then carbon dioxide is added and the air in the kettle is discharged. The particle size of the magnetic powder used as a coloring additive for one-component magnetic insulating toner is generally controlled at 0.1-0.3 microns, the partic...

Embodiment 2

[0028] The difference between this example and Example 1 is that in step A, the hot-melt organic resin that constitutes the main component of the toner and acts as an adhesive is not directly added to the batching system 1 in the form of batching, but is synthesized in the dissolution tank . In the dissolving tank, carbon dioxide supercritical fluid is used as the medium of hot-melt resin polymerization reaction. By controlling the pressure and temperature of carbon dioxide supercritical fluid, dispersion polymerization of styrene-acrylate copolymer and synthesis of polyester resin can be realized. The most commonly used styrene-acrylic copolymer can refer to Desimone's work experience. Methacrylate and styrene are used as monomers, and azobisisobutyronitrile is used as an initiator. It can be selected in supercritical carbon dioxide at 65°C and 204Pa. The block copolymer of 1,1-dihydroperfluorooctylacrylic acid and styrene is used as a dispersant to realize polymerization.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com