On-line continuous automatic cleaning device and method for wax disks

A technology for automatic cleaning and wax plates, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of large reactive power loss of equipment, reduced production, large number of equipment, and damage to wax plate groups Structure and other issues, to achieve the effect of improving equipment utilization, compact equipment structure, and eliminating reactive power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

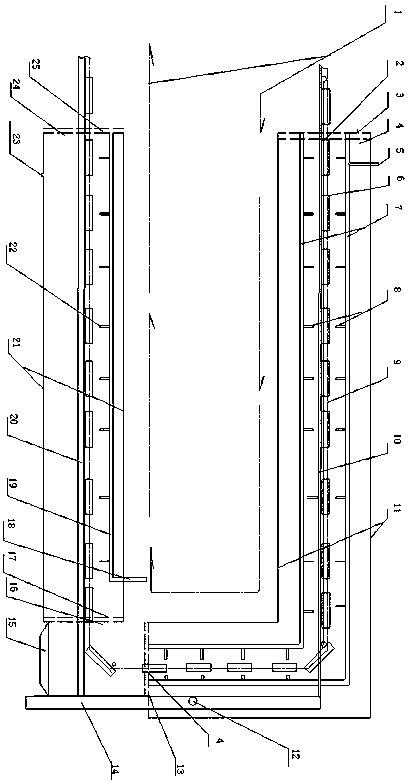

[0028] In order to further understand a wax plate online continuous automatic cleaning device and process flow, the description is as follows in conjunction with the accompanying drawings:

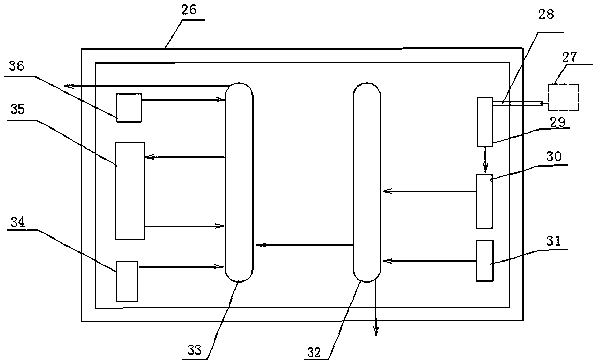

[0029] An online continuous automatic wax plate cleaning device, which includes an air source device, a hot air blowing device, a cooling device and a wax plate conveying device; wherein the air source device includes an outdoor suction fan 27, an air filter 29, an air dehumidifier 30, a purification Air storage tank 32, hot air storage tank 33, heat exchanger 35 and pressure pump 36;

[0030] Wherein the hot-blast purging device comprises a hot-blast casing 11, a hot-blast inlet 5, a hot-blast pipeline 7, several hot-blast blowers 8 and a hot-blast exhaust fan 34; , clean air outlet 23 and cooling wind blower 31; Outdoor suction blower 27 connects air treatment device, and air treatment device 29,30 is connected to clean wind storage tank 32, and clean wind storage tank 32 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com