Heat transfer plate forming device and forming method

A heat transfer plate and workpiece technology, applied in the field of part forming and manufacturing, to achieve the effect of increasing the forming limit, reducing the forming time and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

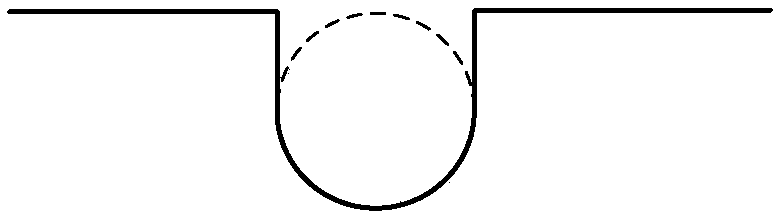

[0043] Such as image 3 As shown, the heat transfer plate forming device is composed of a power supply system 1 , a single-turn electromagnetic driver 2 , a blank holder unit 3 , a conductive electrode 4 and a mold 5 . The single-layer single-turn electromagnetic driver 2 includes a metal sheet 2-1-1 and a skeleton 2-2, and the metal sheet 2-1-1 and the skeleton 2-2 are attached to each other. The single-layer single-turn electromagnetic driver includes multiple single-step electromagnetic drivers. The number of single-step electromagnetic drivers is determined according to the number of forming steps of the workpiece to be formed. The number of forming steps of the workpiece to be formed is determined according to the actual needs of the forming depth and shape of the workpiece. The shape of the side of the single-step electromagnetic driver close to the workpiece to be formed cooperates with the contour shape of the area of the workpiece to be formed or the contour shape o...

Embodiment 2

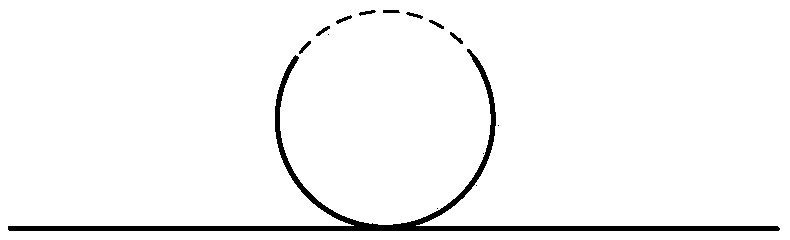

[0048] Correspondingly, the present invention also proposes a heat transfer plate forming method based on the above-mentioned heat transfer plate forming device, comprising the following steps:

[0049] Step 1: Place the workpiece to be formed on the top of the mold reasonably, select a single-step electromagnetic driver according to the shape of the forming, position it and install it on the top of the workpiece to be formed, connect the same end of the single-step electromagnetic driver and the workpiece to be formed through the conductive electrode, and the other end It is connected with the power system to form a loop, and then the workpiece to be formed and the single-step electromagnetic driver are fixed by the blank holder unit.

[0050] Step 2: Charge the capacitor through the power supply system. After the capacitor is charged, discharge the single-step electromagnetic driver and the workpiece to be formed. The single-step electromagnetic driver generates a pulsed magn...

Embodiment 3

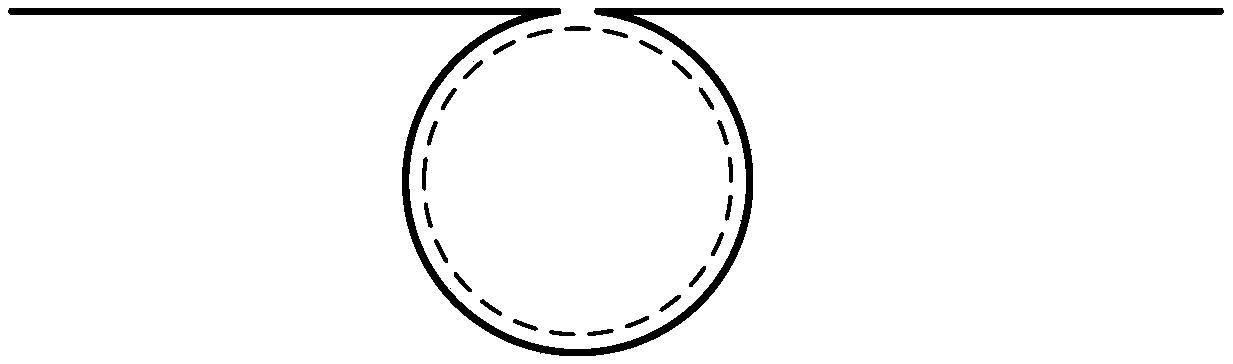

[0060] The difference between this embodiment and the first embodiment is that this embodiment adopts a single-layer multi-turn electromagnetic driver. A heat transfer plate forming device in the form of a multi-turn electromagnetic drive such as Figure 4 shown. The single-layer multi-turn electromagnetic driver 2 is composed of a single-layer multi-turn spiral coil 2-1-2, a skeleton 2-2 and a reinforcement layer 2-3, and the single-layer multi-turn spiral coil 2-1-2 is wound on the skeleton 2 On -2, the reinforcement layer 2-3 is wound around the single-layer multi-turn helical coil 2-1-2, and the reinforcement layer is used to reinforce the helical coil to prevent deformation of the helical coil. The skeleton or reinforcing layer is made of insulating material similar to epoxy resin. Under the same forming conditions, the single-layer multi-turn electromagnetic driver can provide greater electromagnetic forming force than the single-layer single-turn electromagnetic drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com