Size-adjustable perforating machine used for hardware products

A product size and adjustable technology, applied in the field of punching machines, can solve the problems of position deviation of punching hardware products, inability to adjust the clamping of hardware products, affecting later processes, etc., to achieve convenient drilling and smooth adjustment of the drill bit angle. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

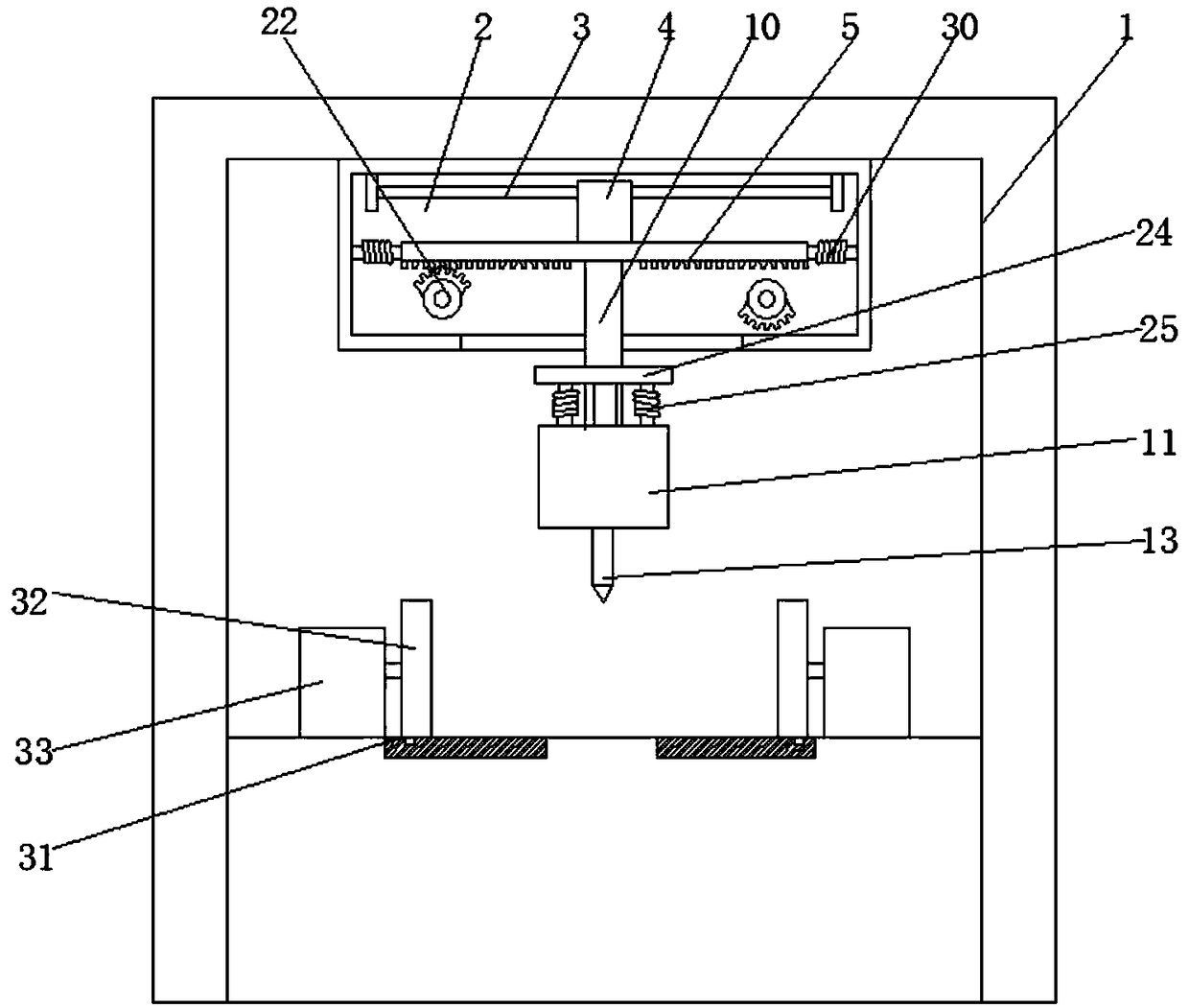

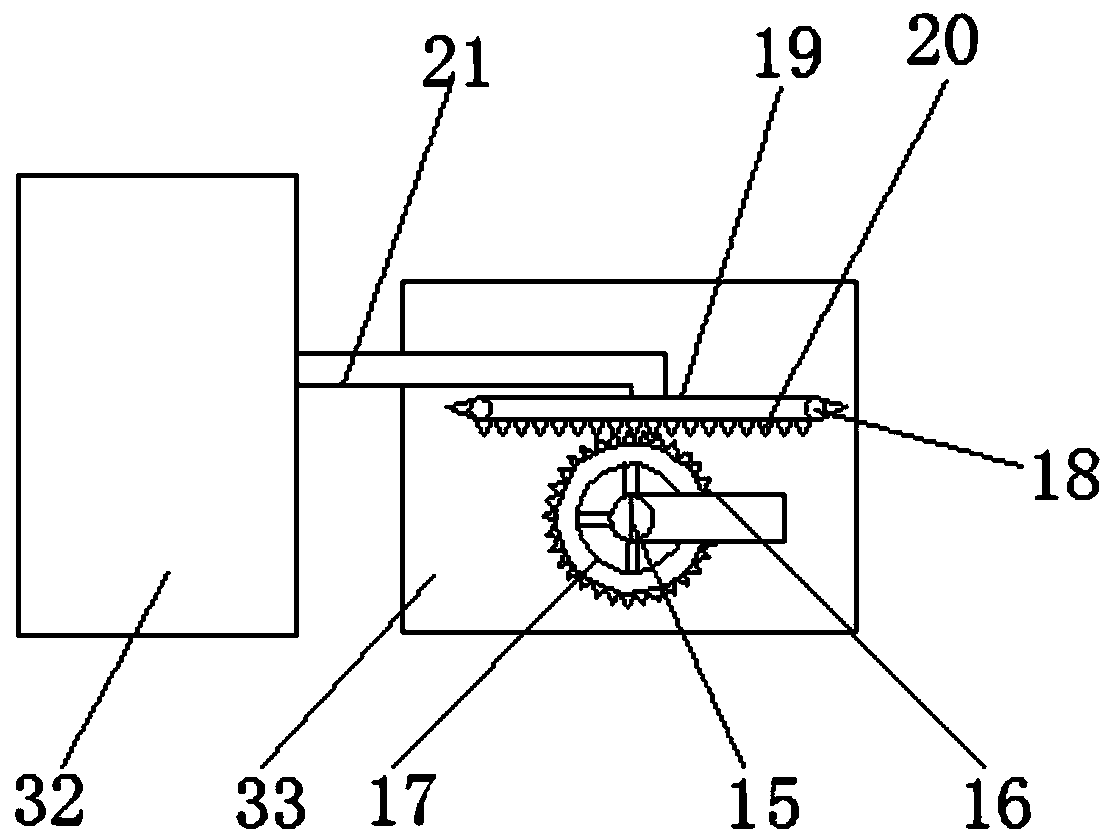

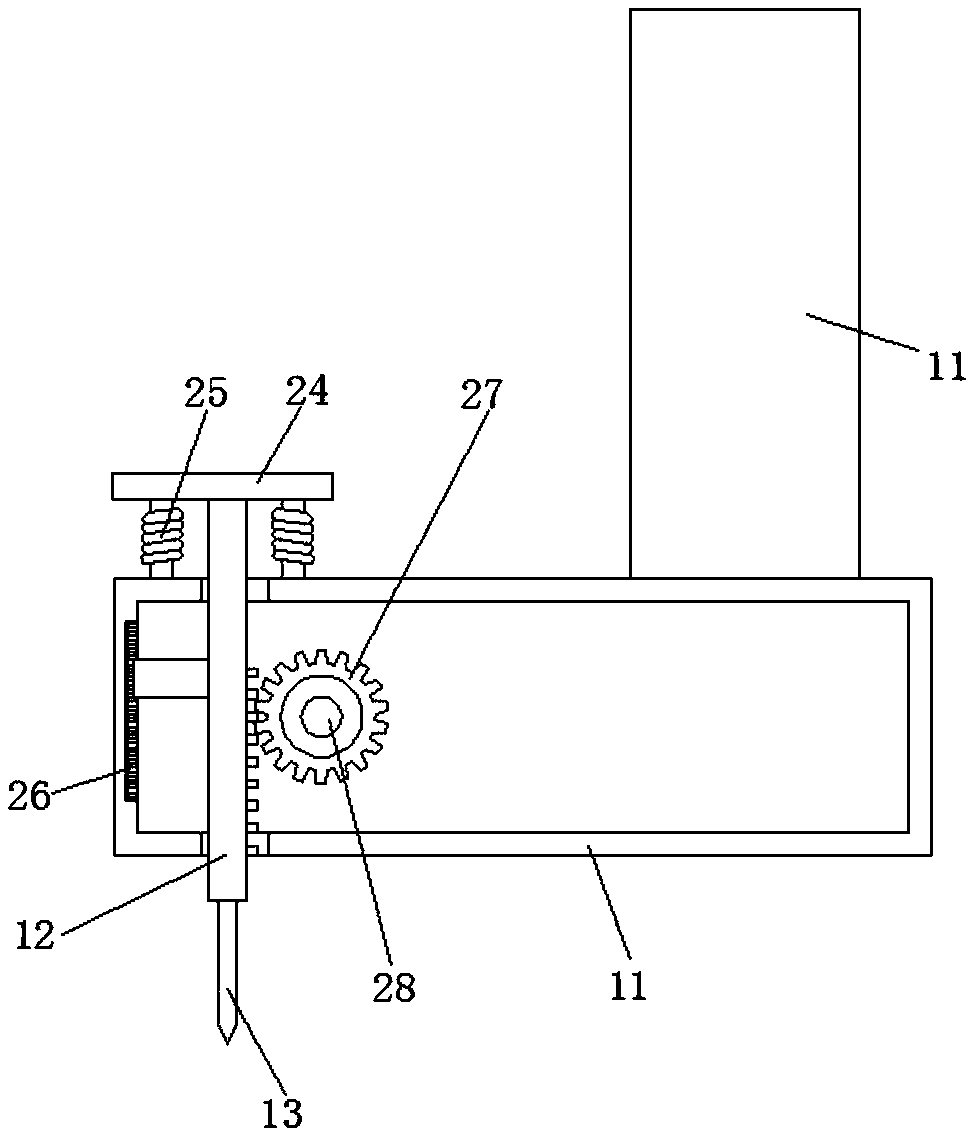

[0024] An embodiment of the present invention provides a size-adjustable punching machine for hardware products, such as Figure 1-4 Shown, comprise cabinet 1, the top of cabinet 1 inner cavity is fixedly installed with mobile box 2, by arranging mobile box 2, drill bit 13 can be moved left and right, the rotation range of drill bit 13 is enlarged, and the top of mobile box 2 inner cavity is fixedly installed There is a slide bar 3, the outer side of the slide bar 3 is provided with a slide block 4, the bottom of the slide block 4 is fixedly equipped with a first rack 5, and both sides of the first rack 5 are fixedly equipped with shock absorbing springs 30 for shock absorption. One end of the spring 30 away from the rack is fixedly connected to both sides of the inner chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com