Cooling device for metal product casting

A technology for cooling devices and metal products, which is applied in the direction of solid separation, sieves, grills, etc., can solve the problems of insufficient cooling, time-wasting, and reduced work efficiency of metal manufacturing, so as to improve the effect of falling water, improve cooling efficiency, and speed up Effect of Cooling Drying Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

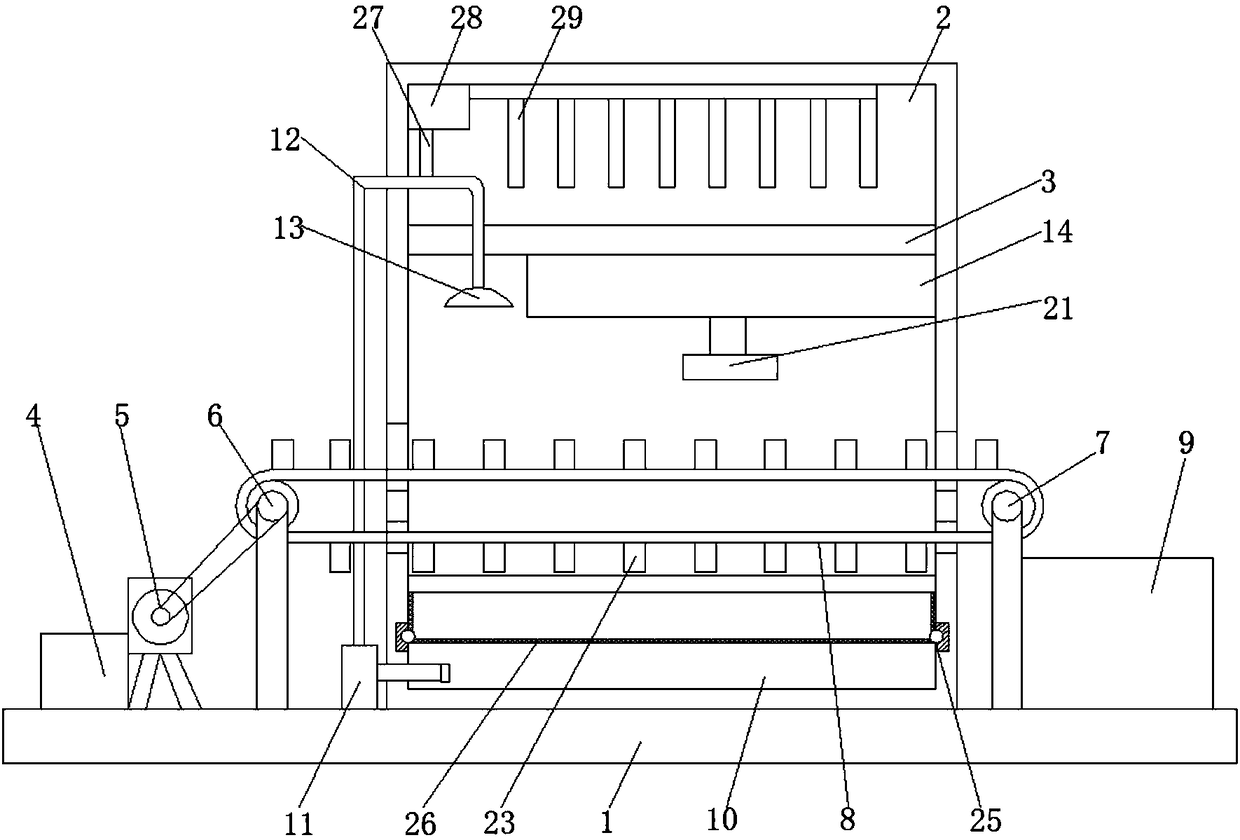

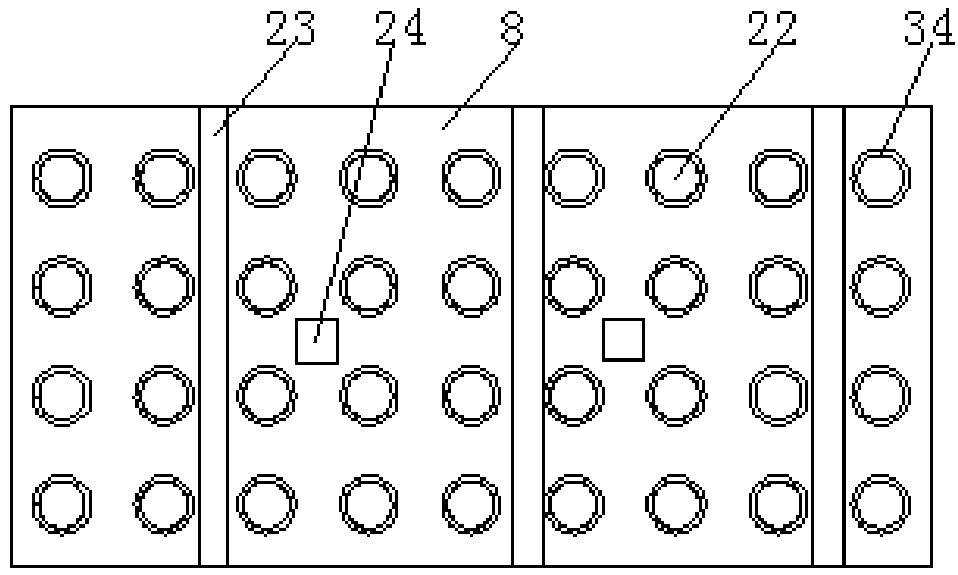

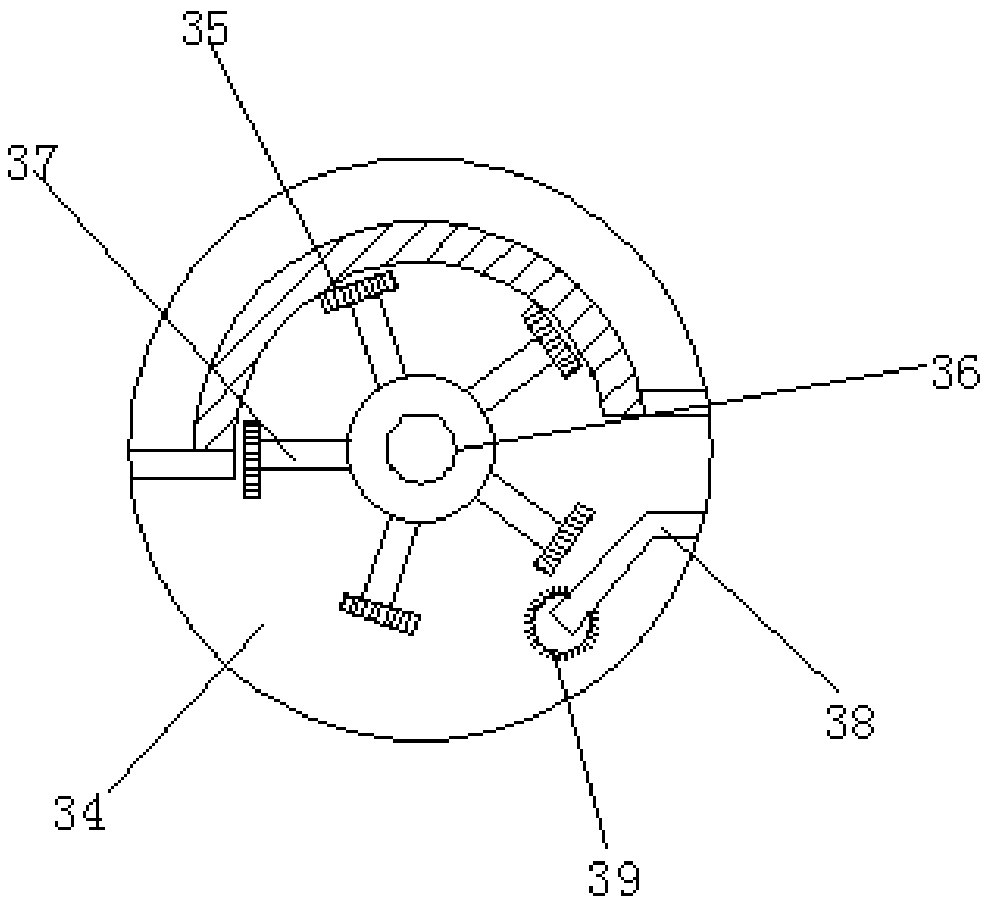

[0026] An embodiment of the present invention provides a cooling device for casting metal products, such as Figure 1-5 As shown, it includes a bottom plate 1, a box body 2 is fixedly installed on the top of the bottom plate 1, a beam 3 is fixedly installed inside the box body 2, a first motor 4 is arranged on the left side of the box body 2, and a first motor 4 is fixed on the right side of the first motor 4. The driving runner 5 is connected, and the left side of the box body 2 is respectively provided with a feeding runner 6 and a driven runner 7, and the conveyor belt 8 is driven by the feeding runner 6 and the driven runner 7 to transmit metal products, which reduces the labor force. The working efficiency is improved, the driving runner 5 and the feeding runner 6 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com