Performance detection device for ejection control mechanism and application method thereof

A control mechanism and detection device technology, which is applied in the direction of ejection/departure device, aircraft component testing, etc., can solve the problems affecting the repair quality of the ejection control mechanism, the difficulty of accurate measurement, and the low test accuracy, so as to overcome the single performance detection and repair. Reliable quality, the effect of solving large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

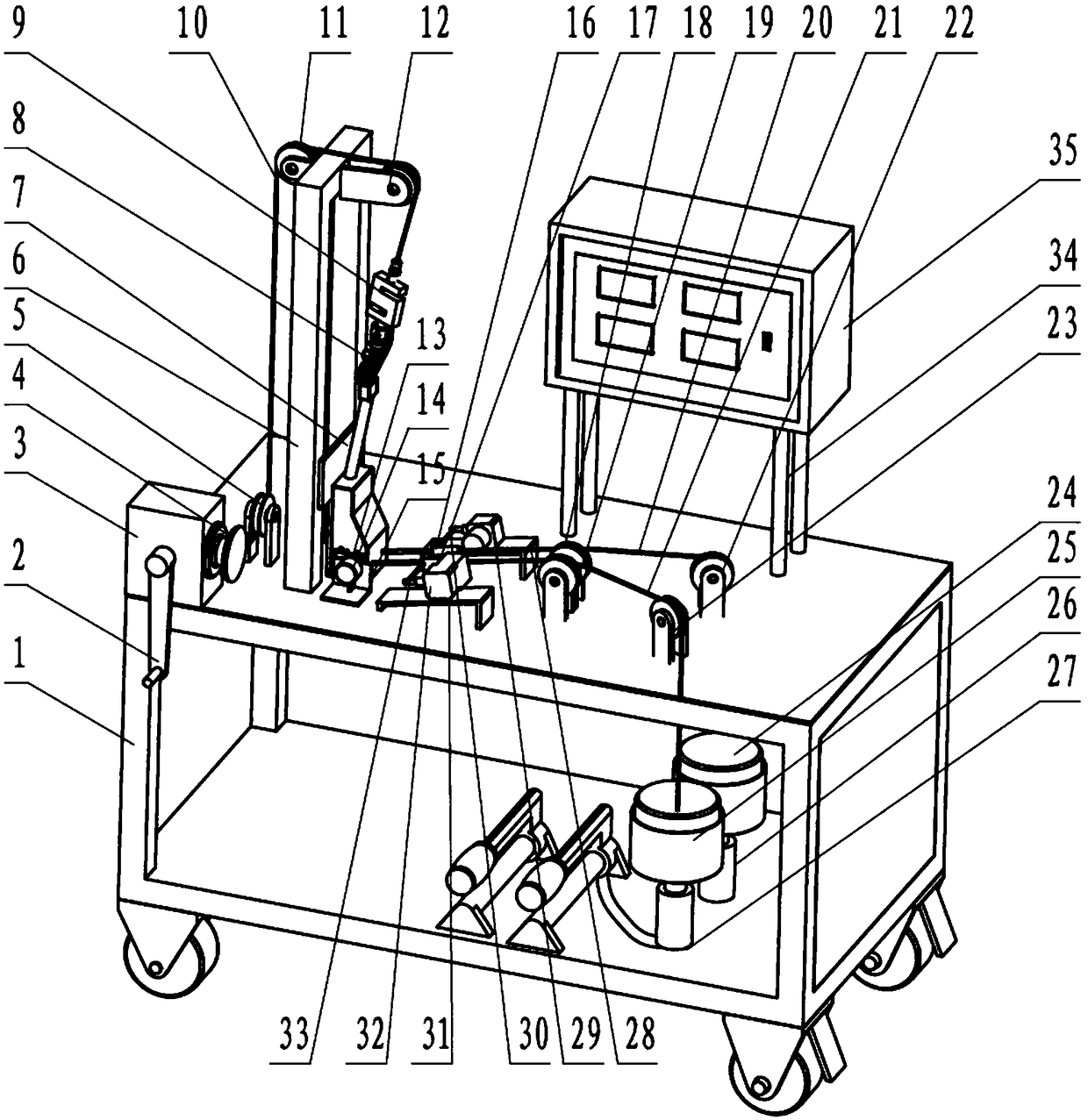

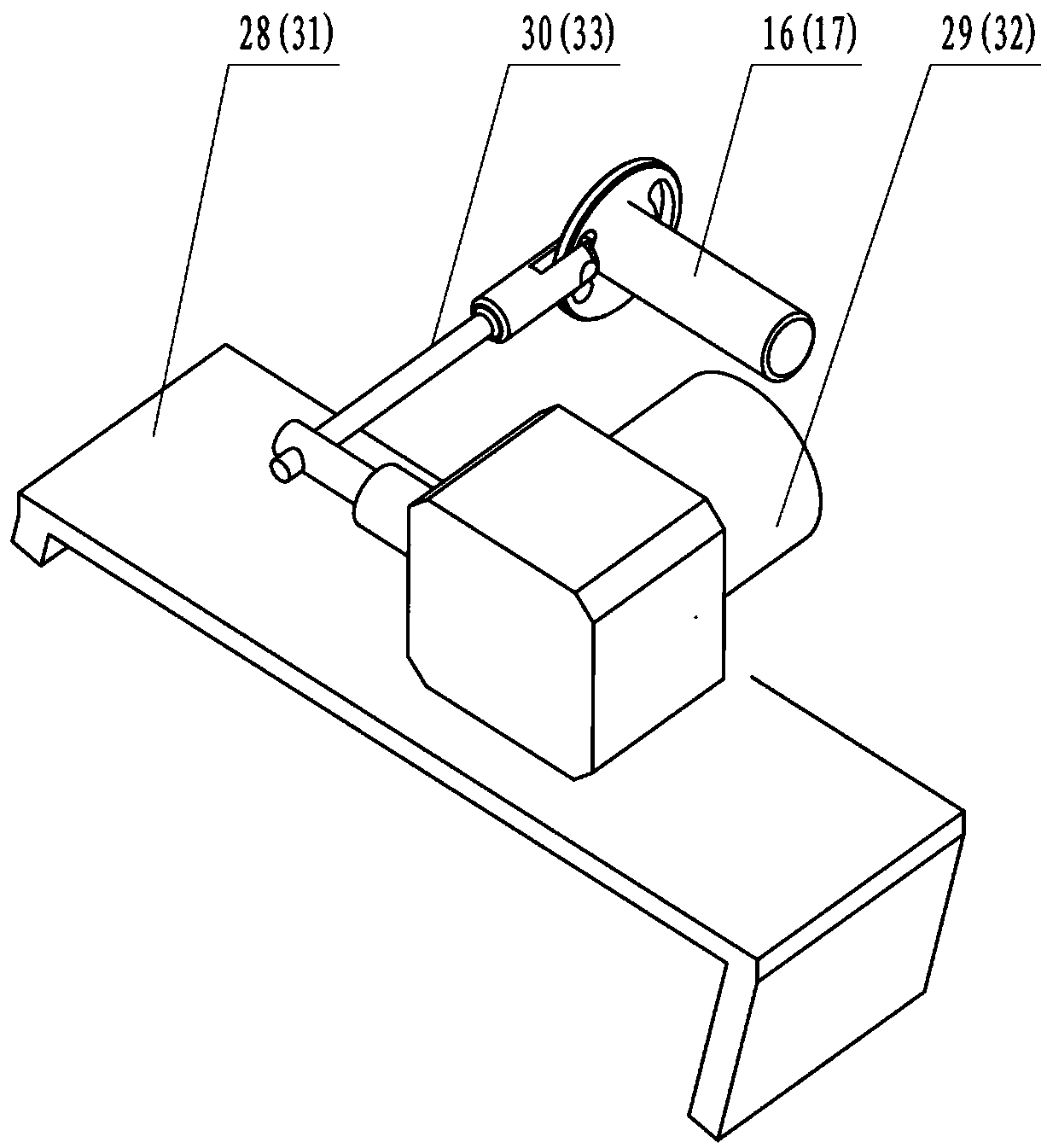

[0028] Such as figure 1 and figure 2 As shown, a performance detection device for an ejection control mechanism includes a work cabinet 1 and an electrical control box assembly arranged on the work cabinet 1. The work cabinet 1 is provided with a reducer assembly for providing power and controlling speed. The work cabinet 1 is also provided with a fixed bracket assembly, the fixed bracket assembly is provided with a cable assembly for power transmission that cooperates with the reducer assembly, and the cable assembly is provided with a handle tooling 8, An angular displacement sensor assembly is arranged on the fixed bracket assembly, a first displacement sensor assembly and a second displacement sensor assembly cooperating with the angular displacement sensor assembly are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com