Automatic recovery equipment for no-load jig

An automatic recovery and jig technology, applied to conveyors, storage devices, roller tables, etc., can solve problems such as low efficiency and cumbersome operation, and achieve the effects of improving recovery efficiency, shortening time loss, and saving mechanism installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

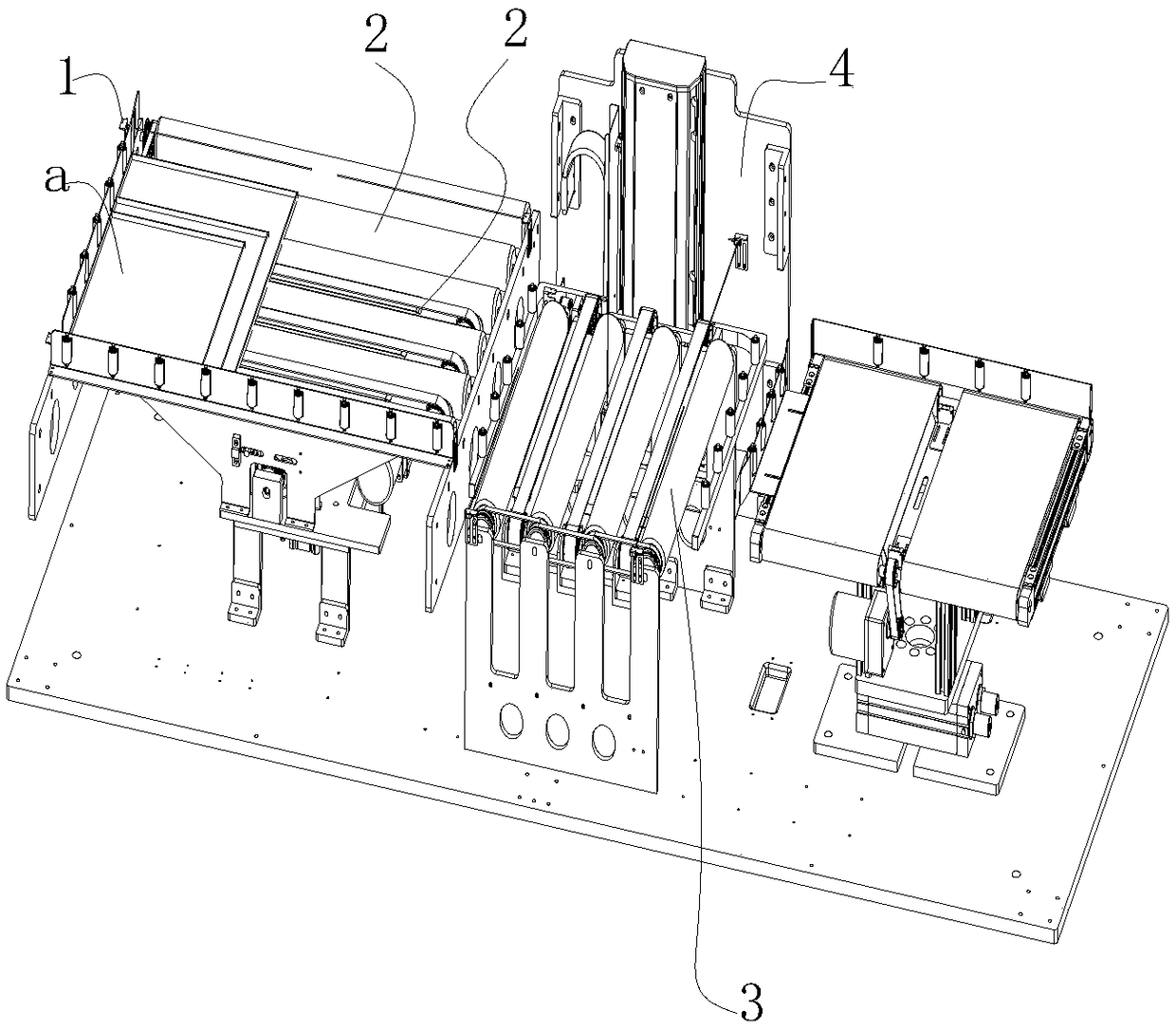

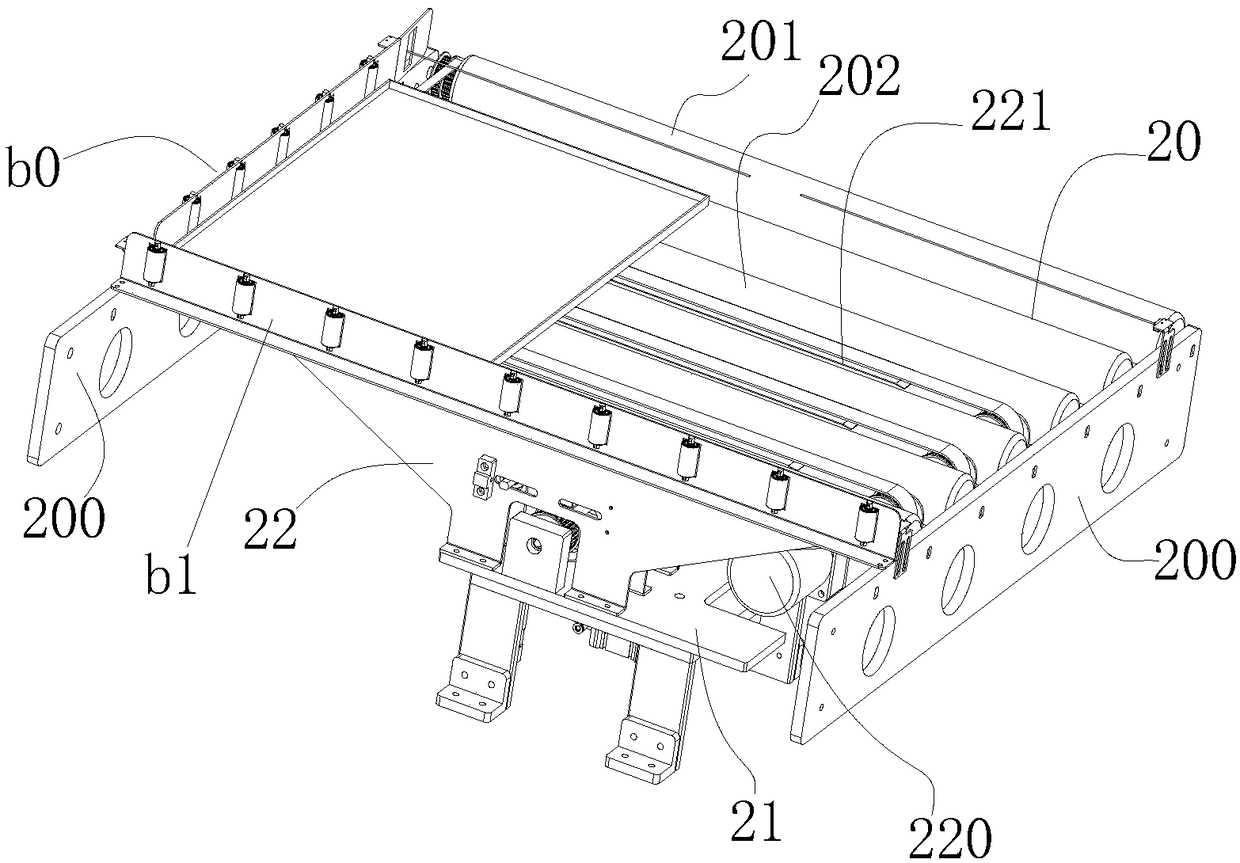

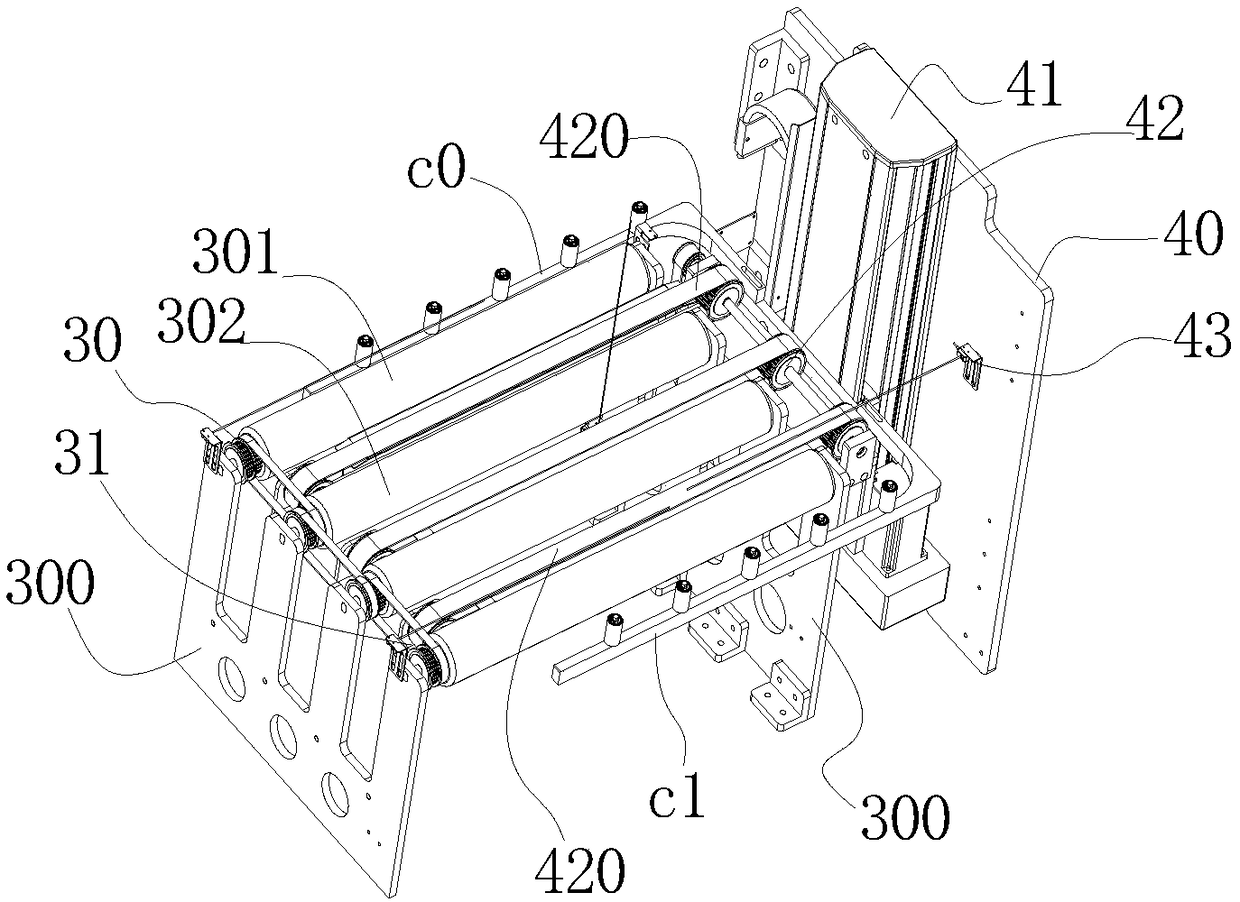

[0058] see figure 1 , Embodiment 1 provides an automatic recovery device for empty fixtures, including: an empty tray AGV arrival sensor 1 , an empty tray pick-up mechanism 2 , a transfer roller mechanism 3 and a lifting belt mechanism 4 .

[0059] On the one hand, the empty disk AGV arrival sensor 1 is used to sense the empty disk AGV (not shown) in place, so as to send an empty disk AGV arrival signal.

[0060] It should be noted that after the AGV transports the empty disk a that needs to be recovered to the designated recovery position, the empty disk AGV in-position sensor 1 is required to sense and collect the AGV's in-position information, so as to achieve the effect of automatically judging the AGV's in-position.

[0061]On the other hand, the empty disk pick-up mechanism 2 receives and responds to the empty disk AGV arrival signal to pick up the empty disk a on the empty disk AGV (not shown) and transport the empty disk a to the transfer station.

[0062] It should b...

Embodiment 2

[0102] see Figure 4 and Figure 5 , Embodiment 2 provides an automatic recovery device for empty jigs. On the basis of Embodiment 1, the recovery device further includes: an empty box AGV arrival sensor 5 and an empty box receiving mechanism 6 .

[0103] On the one hand, the empty box AGV in-position sensor 5 is used to sense the empty box AGV (not shown) in place to send an empty box AGV in-position signal.

[0104] It should be noted that after the AGV transports the empty box (not shown) to be recycled to the designated recycling location, the empty box AGV arrival sensor 5 is required to sense and collect the AGV arrival information, so as to achieve the effect of automatically judging the AGV arrival .

[0105] On the other hand, the empty box pick-up mechanism 6 is arranged side by side with the transfer roller mechanism 3, and is used to receive and respond to the empty box AGV arrival signal, to pick up the empty box (not shown) on the empty box AGV (not shown) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com