Soft pipe offset machine vibrating disk feeding device

A technology of feeding device and vibrating disc, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of affecting printing efficiency and damage to bottle cap printing rollers, so as to improve printing efficiency, increase lifting speed, deliver good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes the present invention in further detail in conjunction with the description of the drawings and the specific embodiments:

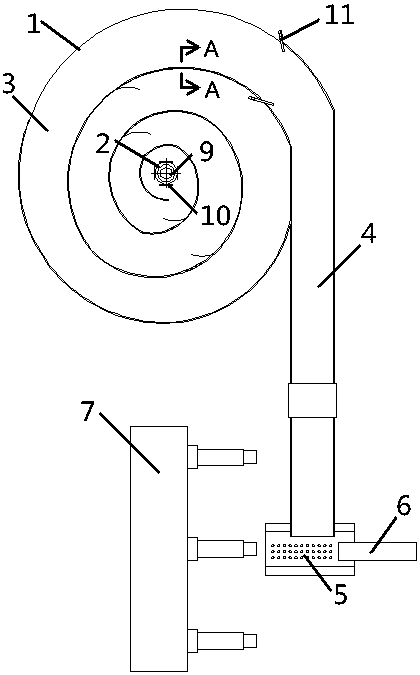

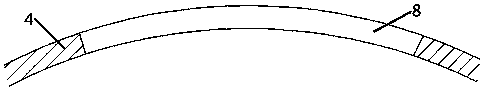

[0017] See Figure 1-Figure 2 , A vibrating disc feeding device for a hose offset printing machine, comprising a vibrating disc 1, the volume of the vibrating disc 1 exceeds the volume of a box of bottle caps, and a transformer 9 and a manganese steel bar 10 are installed at the bottom of the vibrating disc 1. The manganese steel bars 10 are respectively fixed on the four sides of the transformer 9. The top of the manganese steel bars 10 is fixedly connected with the bottom of the vibrating plate 1. The inner wall of the vibrating plate 1 is provided with a bottom-up spiral channel 3, the spiral channel The side wall of 3 is provided with a blowing nozzle 11, the outlet of the spiral channel 3 is connected with a feeding channel 4, and the outlet of the feeding channel 4 is located above the pusher plate 5. The ends are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com