Gravity tensioning device

A tensioning device and gravity technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of increasing the complexity of the ground power generation system, increasing the area occupied by the ground power generation system, and the structure of the ground power generation system. The effect of small footprint, simple structure, and reduced layout difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

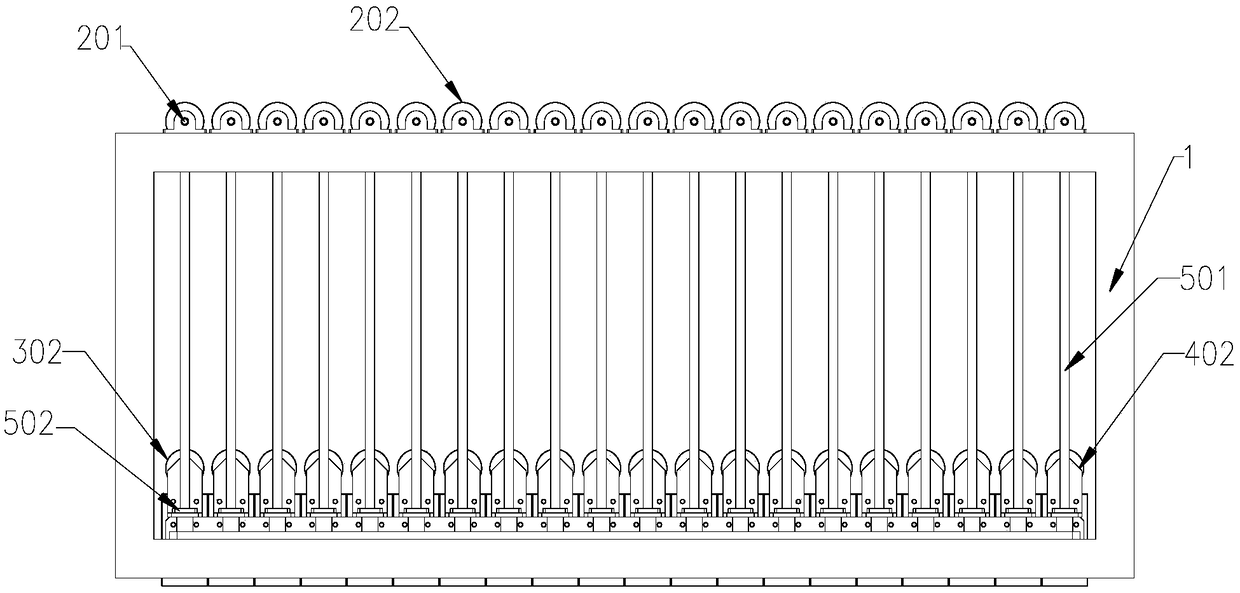

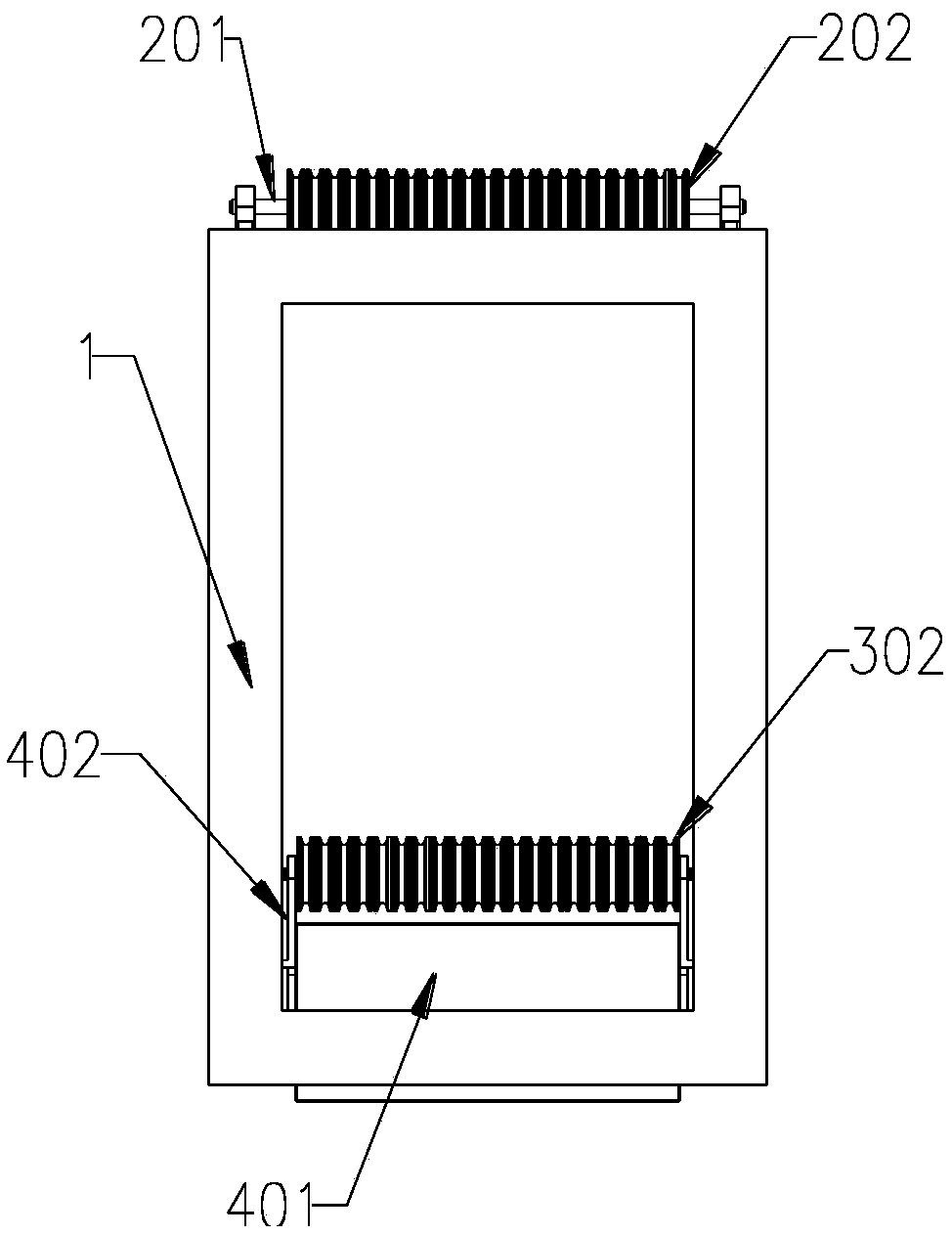

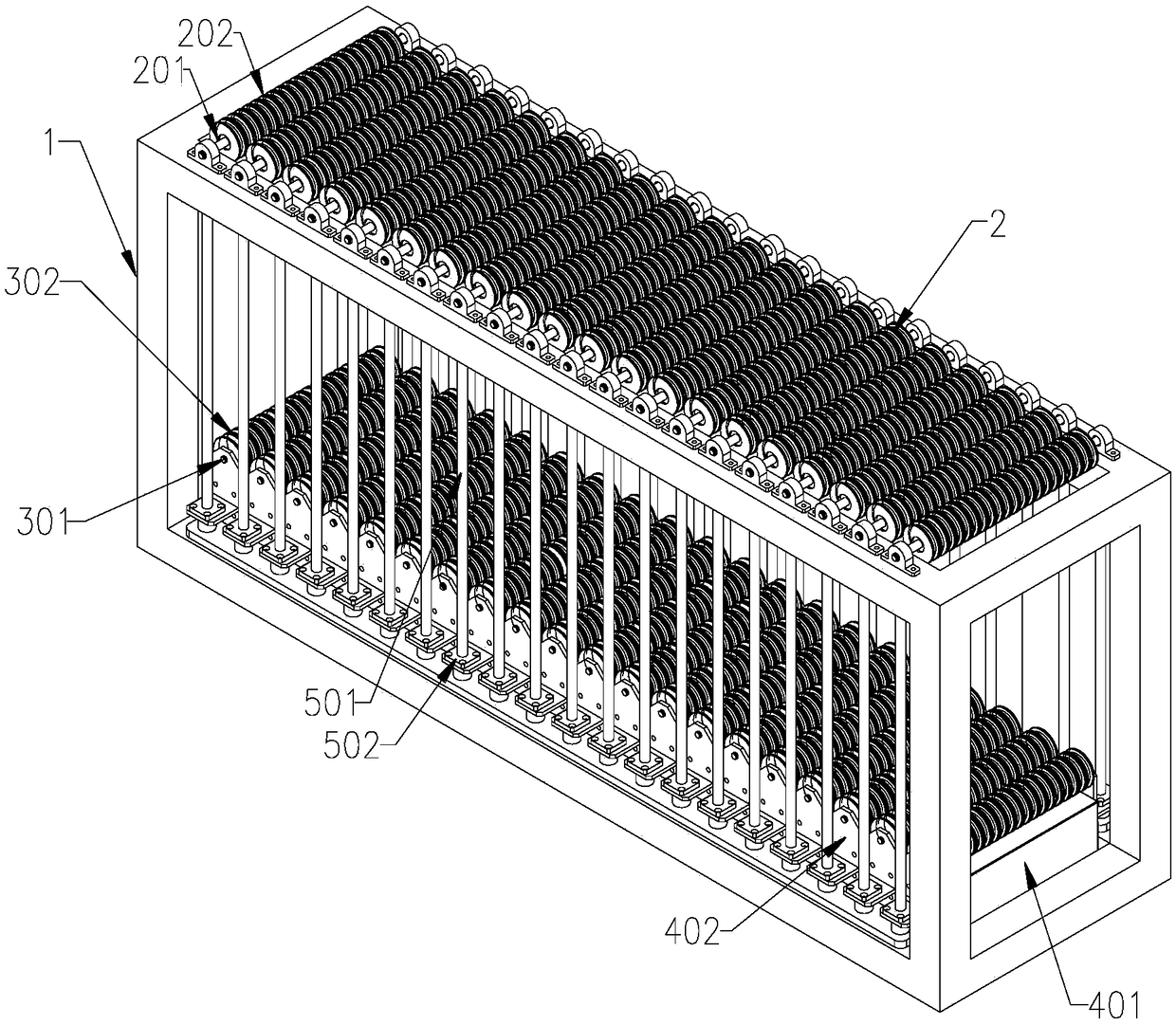

[0028] Such as Figure 1~3 As shown, this embodiment provides a gravity tensioning device, which is mainly used in the field of high-altitude wind power generation. Frame 1 bottom, movable pulley block 3 that is arranged in parallel; Described fixed pulley block 2 comprises the first fixed shaft 201 that is installed on the described frame, and some fixed pulleys 202 are installed on the described first fixed shaft 201; Described movable pulley block It includes a second fixed shaft 301 on which a number of movable pulleys 302 are installed; a row of the fixed pulleys 202 corresponds to a row of the movable pulleys 302 .

[0029] Specifically, each fixed pulley and each movable pulley in the corresponding fixed pulley block and movable pulley block also correspond to each other respectively. As a preferred situation, the corresponding fixed pulleys and movable pulleys are on the same vertical plane. Assuming that the corresponding fixed pulley and movable pulley are a pulley ...

Embodiment 2

[0039] This embodiment provides a gravity tensioning device, which is mainly used in the field of high-altitude wind power generation. On the first fixed shaft, a number of fixed pulleys are installed on the first fixed shaft; it also includes a number of movable pulleys arranged at the lower part of the frame, and the movable pulleys correspond to the fixed pulleys; each movable pulley is also connected with a counterweight, counterweight The overall trend is light at the front and heavy at the end.

[0040] Among them, for the gravity tensioning device, the cable is wound one by one from the entrance of the rope, one fixed pulley and one movable pulley, and finally fixed on the last movable pulley / fixed pulley. Therefore, the fixed pulley / moving pulley wound first is the front, The final fixed pulley / moving pulley is the rear.

[0041] The weight of the counterweight of the movable pulley increases evenly from front to back. Specifically, the counterweight of the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com