Aluminum Alloy Rods and Glass Fiber Reinforced Polyester Plates Bending Reinforced Glass Beam Members

A glass fiber and glass plate technology, applied in building components, building structures, walls, etc., can solve the problems of unsafe bending failure mode, low bending bearing capacity, low fracture toughness, etc., and achieve enhanced collaborative work ability, Enhanced safety reserve, effect of beam durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

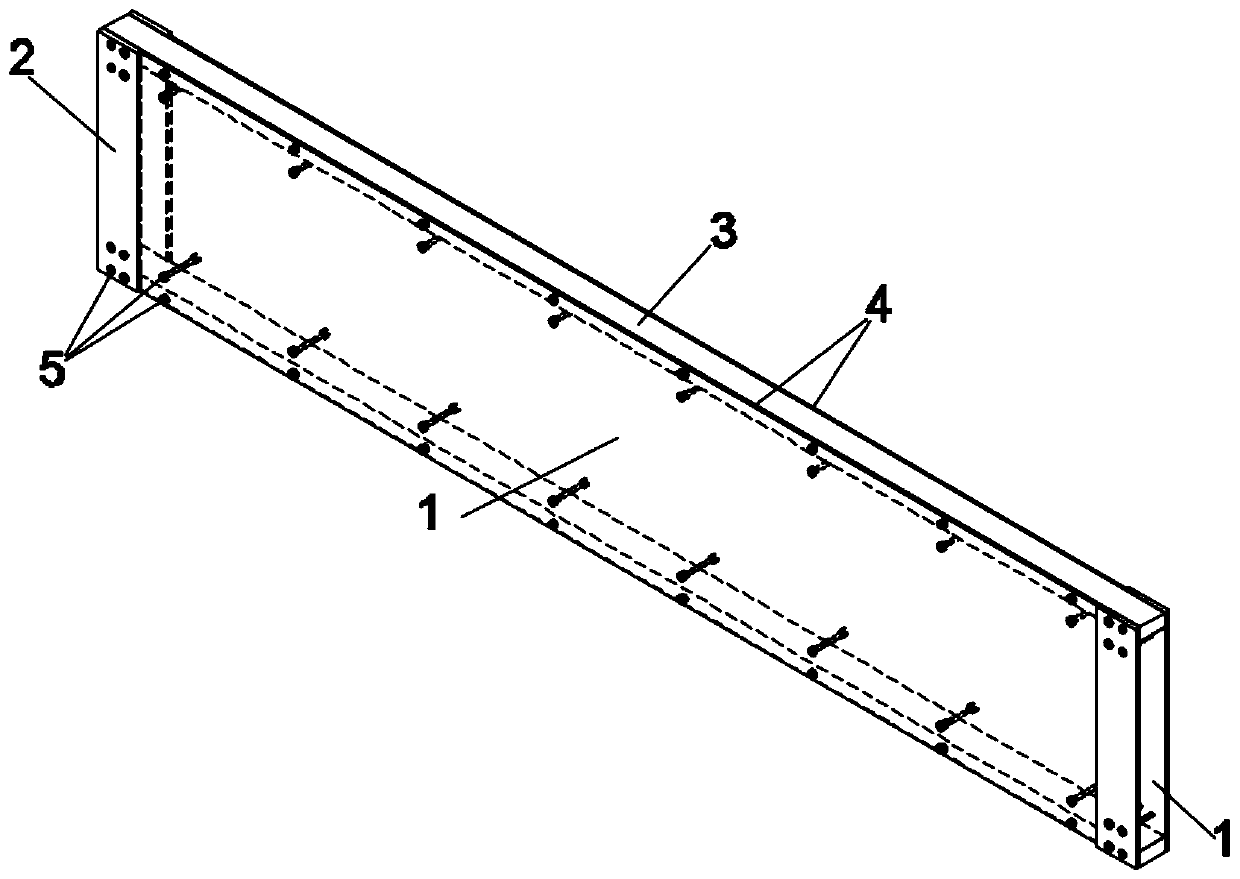

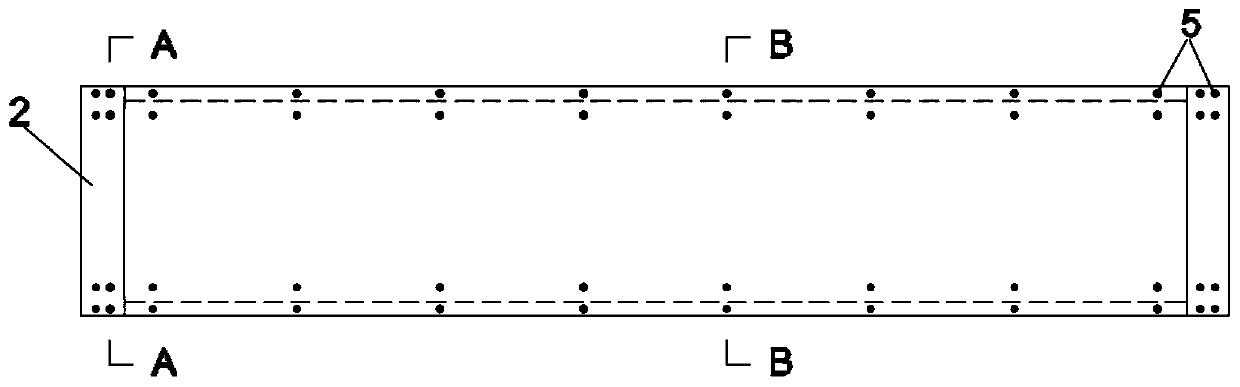

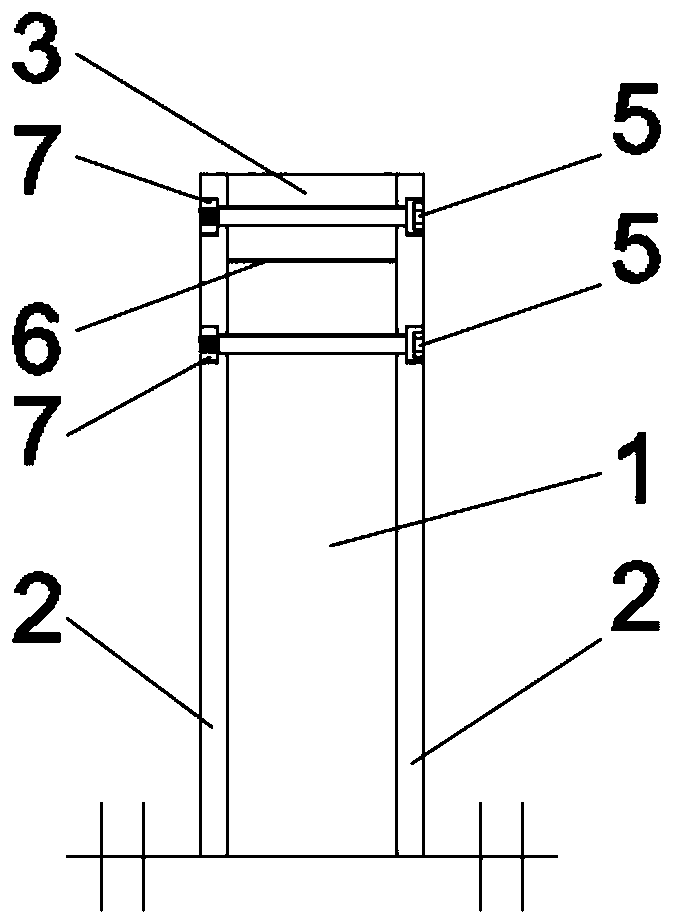

[0032] Such as Figure 1 to Figure 4 As shown, the present invention provides an aluminum alloy rod and a glass fiber reinforced polyester plate reinforced glass beam member, including a glass plate 1, a square aluminum rod 3 bonded to the upper and lower ends of the glass beam section, and the bonding used UV curing adhesive 6, steel plate 2 used to anchor the square aluminum rod 3 at the end of the glass beam, transparent and colorless fiber reinforced material sheet 4 anchored on both sides of the glass beam section, and pressure-bearing bolts used for anchoring 5.

[0033] Further, the glass plate 1 is made of ordinary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com