CG-3 tunnel arch abutment establishing vehicle

A CG-3, arch trolley technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of high labor intensity of personnel, laborious manual handling and lifting, etc., and achieve easy grasping of the arch frame, low risk factor, and safety. The effect of large coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

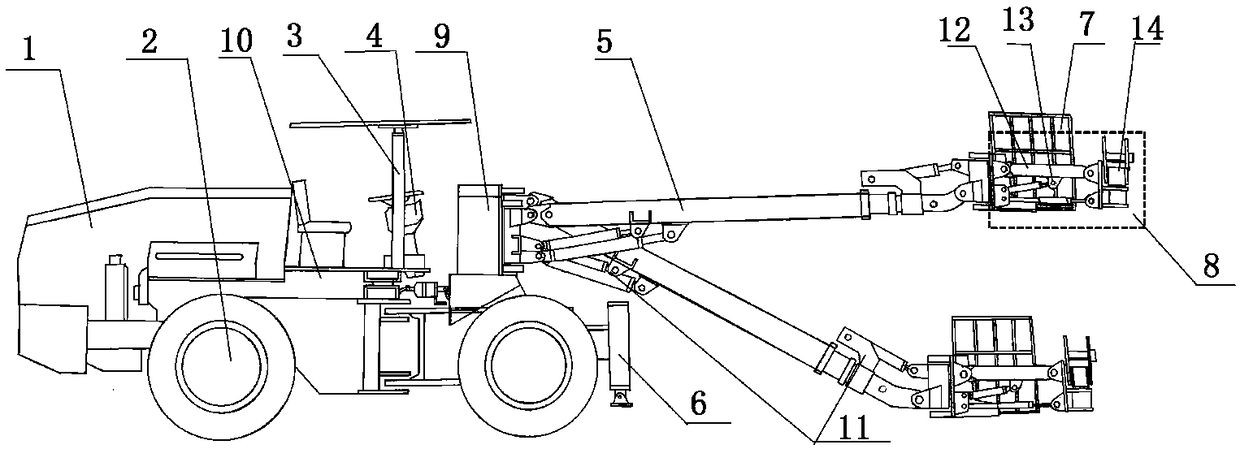

[0029] CG-3 tunnel vertical arch trolley described in the present invention, see figure 1 , including vehicle frame, chassis walking system, cab, console control system, main arm assembly, hydraulic outriggers, working platform and hydraulic clamp assembly; the vehicle frame is composed of a front frame and a rear frame, and the The front frame and the rear frame are set on the chassis walking system, and the hydraulic system, electrical system, cab and console control system are installed on the rear frame, and the top of the cab is set above the console control system , the hydraulic system and electrical system are connected with the console control system; three main arm assemblies are arranged side by side on the front frame, and the main arm assemblies swing in four directions: up, down, left and right, and the main The rear support of the arm assembly is connected with the front frame, the front support of the main arm assembly is connected with the working platform and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arm length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com