LED automotive lamp with radiating mechanism, manufacturing technology of LED automotive lamp with radiating mechanism and control method

A technology of LED car lights and heat dissipation mechanism, which is applied in the direction of headlights, motor vehicles, road vehicles, etc. It can solve the problems of burning lamp beads, reducing driving safety, and incapable of heat dissipation of lights, so as to achieve improved heat dissipation and good heat dissipation performance , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

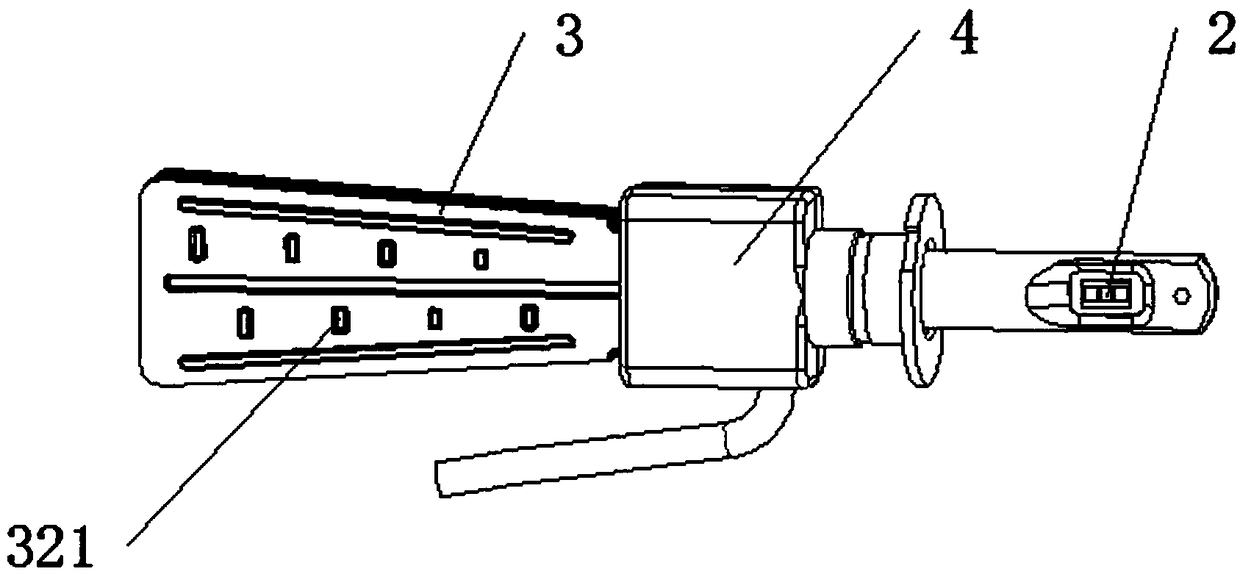

[0041]In this embodiment, after the copper sheets 3 are scattered, except that the integrated part 31 is compressed, the heat dissipation part 32 is scattered in a flocculent shape, and the protrusions 321 between each copper sheet 3 are pushed apart from each other, which can only be arranged on the The same side of each copper sheet 3 can also be provided with protrusions on both sides, and the protrusions face each other to increase the contact area between the heat dissipation part 32 and the air and speed up the heat dissipation rate.

Embodiment 2

[0043] Different from Embodiment 1, in this embodiment, the heat dissipation portion 32 of the copper sheet 3 extends in a wave shape, and the copper sheets 3 are spread out one by one through the transverse wave-shaped heat dissipation portion 32, as shown in FIG. Figure 4 As shown, such a setting is easier to bend and shape during production, and the shape of the wave can gradually increase in amplitude. The bottom of the wave is opposite to the top of the other wave, forming a large-area contact between the cavity and the air, increasing the effect of heat dissipation .

Embodiment 3

[0045] The difference between this embodiment and Embodiment 2 is that the wave extending direction of the wavy cooling portion 32 is longitudinal, as Figure 5 As shown, the copper sheet 3 will be more orderly, and the bottom end of the wave is easier to align with the top of the other sheet. It can also achieve the purpose of opening the copper sheet 3 and increase the contact area with the air to improve the heat dissipation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com