Vertical-type heat-storage water tank having built-in coil pipe with thermal stratification function

A heat storage tank and temperature stratification technology, which is applied to solar collectors, solar heat storage, and fluid heaters using working fluids, and can solve the problem of reduced utilization of solar energy or low-grade energy, and small temperature range of water supply , There are no layering measures for the water tank, etc., which has achieved great practical significance in production, efficient and reliable operation, and is conducive to the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

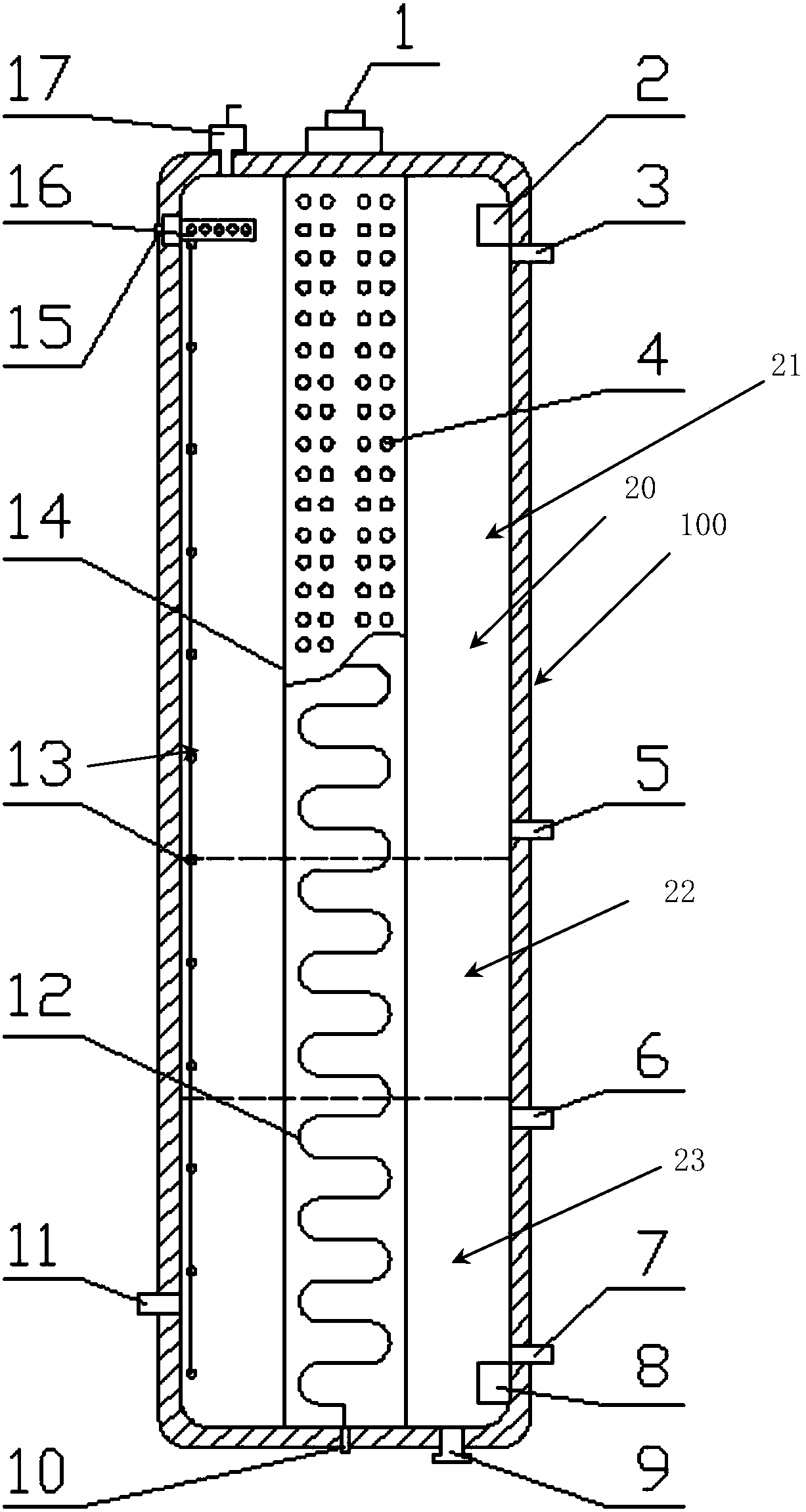

[0035] see figure 1 , the present invention provides a vertical temperature stratified heat storage tank with a built-in coil, including a heat storage tank shell 100, and the heat storage tank shell 100 has an inner chamber 20 of the heat storage tank ;

[0036] The inner chamber 20 of the hot water storage tank includes a chamber 21 in a high temperature zone, a chamber 22 in an oblique temperature zone and a chamber 23 in a low temperature zone that are distributed sequentially from top to bottom and communicate with each other;

[0037] A heat exchange coil 12 vertically distributed from top to bottom is arranged at the lateral middle position of the inner chamber 20 of the heat storage tank, and the exterior of the heat exchange coil 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com