Fault detection method and device for rotating mechanical equipment

A rotating mechanical equipment and fault detection technology, which is applied in the testing of mechanical components, measuring devices, and testing of machine/structural components, can solve problems such as inability to effectively detect faults, and achieve the effect of improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

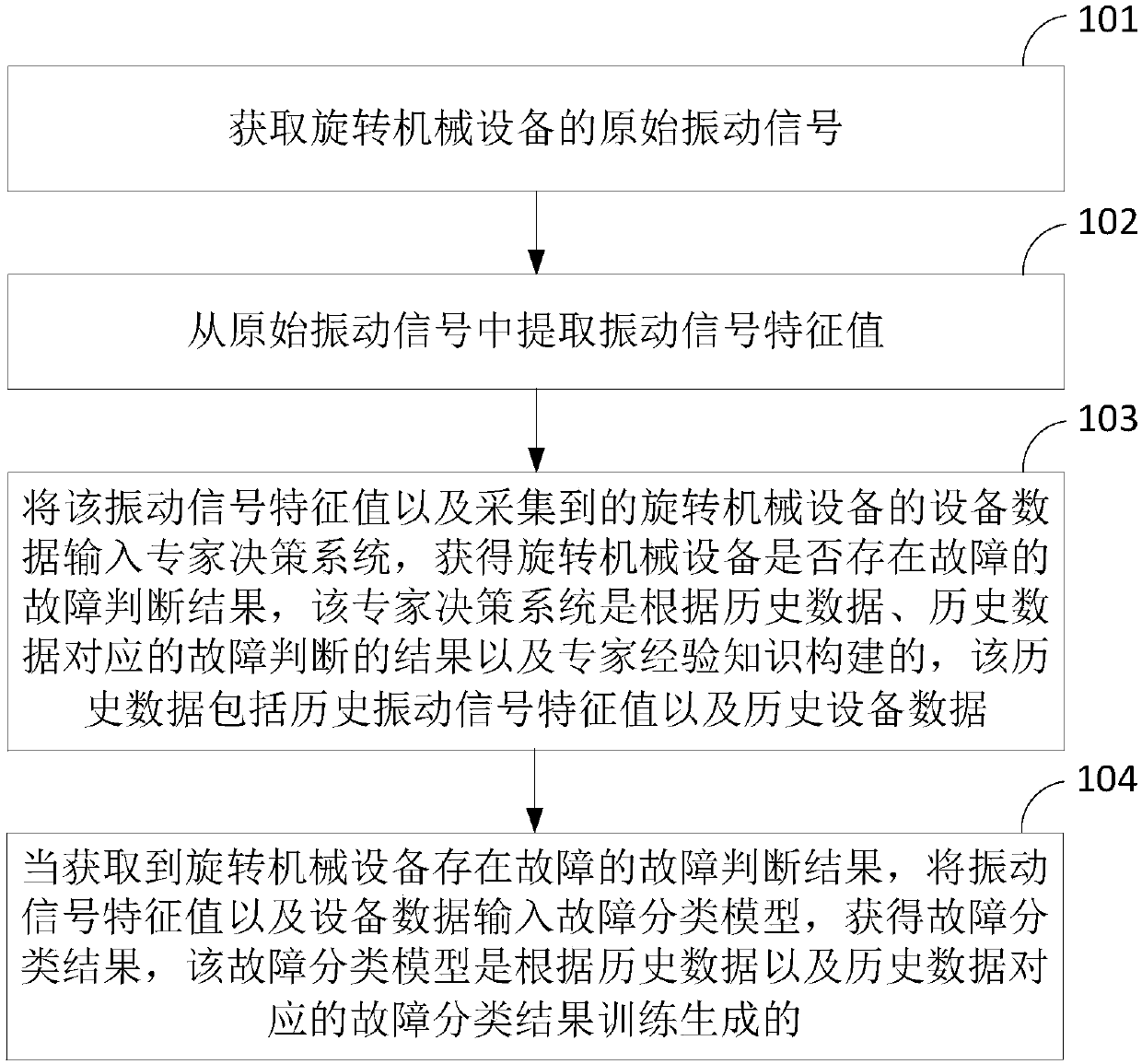

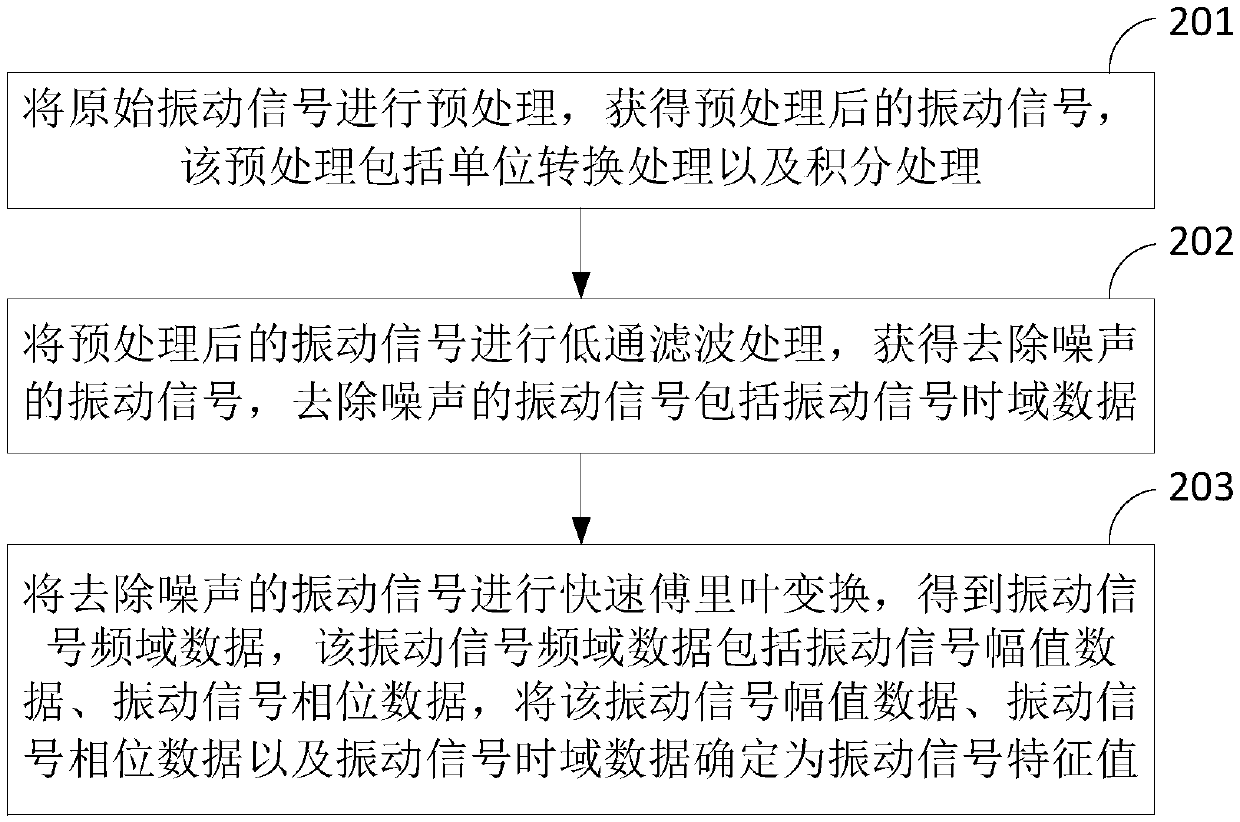

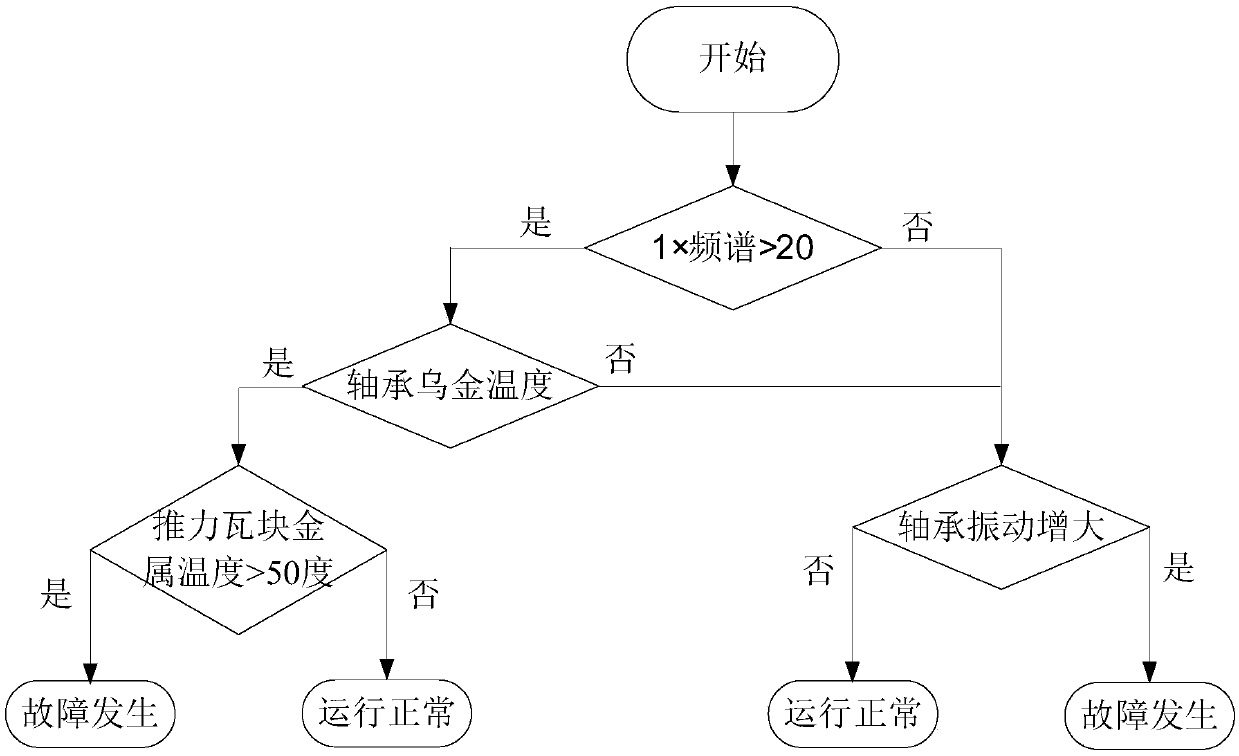

[0041] In order to make the above objects, features and advantages of the present application more obvious and understandable, the embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0042] With the rapid development of modern industry, rotating mechanical equipment is used as the prime mover to drive various production equipment. Once it breaks down and stops working, it will lead to the stagnation of the entire production process and cause immeasurable economic losses. Therefore, for its Research on real-time state monitoring and fault detection of operations has also become particularly important. The traditional monitoring of the state of rotating machinery equipment uses fixed threshold monitoring and fault judgment, which can solve the monitoring problem of a class of state universally. The existing monitoring methods have been unable to effectively detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com