Detection control device and method for fineness modulus

A fineness modulus, detection and control technology, used in measuring devices, program control, general control systems, etc., can solve the problem that the quality parameters of machine-made sand cannot be accurately controlled, the fineness modulus cannot be fed back in time, and the stability of concrete cannot be guaranteed. problems, to ensure stability, improve quality and production efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

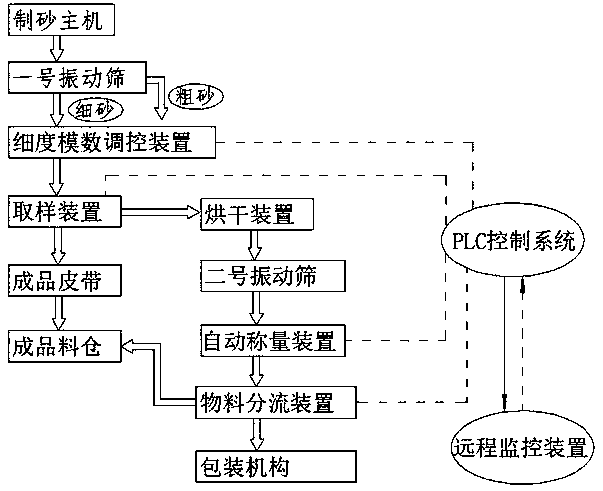

[0022] Such as figure 1 As shown, a detection and control device for fineness modulus, which is used for on-line detection and regulation of fineness modulus of finished sand on the sand making production line, includes a sand making main machine, the discharge port of the sand making main machine and the No. The vibrating screen is connected to the vibrating screen. The vibrating screen is set on more than one floor. The bottom of the vibrating screen is provided with a fine sand outlet, and the side is provided with a large-size material channel and a coarse sand channel. The large-size material channel is connected to the sand making machine. The screened large particle size material is returned to the sand making machine for re-crushing, the coarse sand chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com