Surface light source backlight module and liquid crystal display panel

A liquid crystal display panel and backlight module technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as uneven brightness, haze particles that cannot achieve a better light mixing effect, and affect the overall brightness of surface light sources. Improve the transmittance and brightness, facilitate the thinning design, and improve the uniformity of light mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

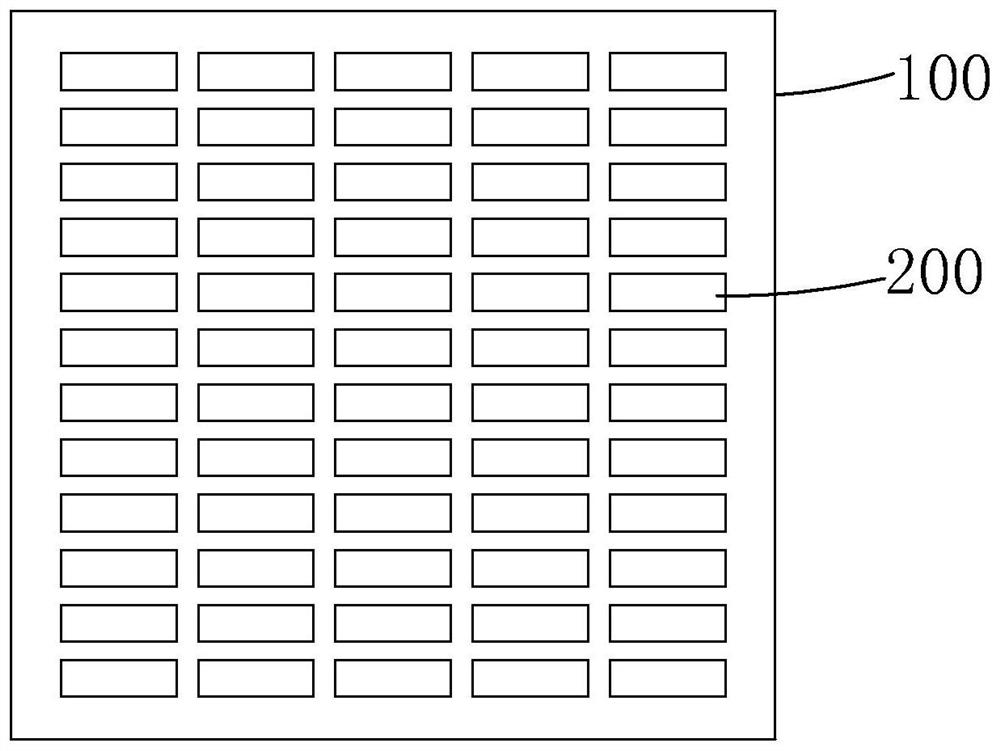

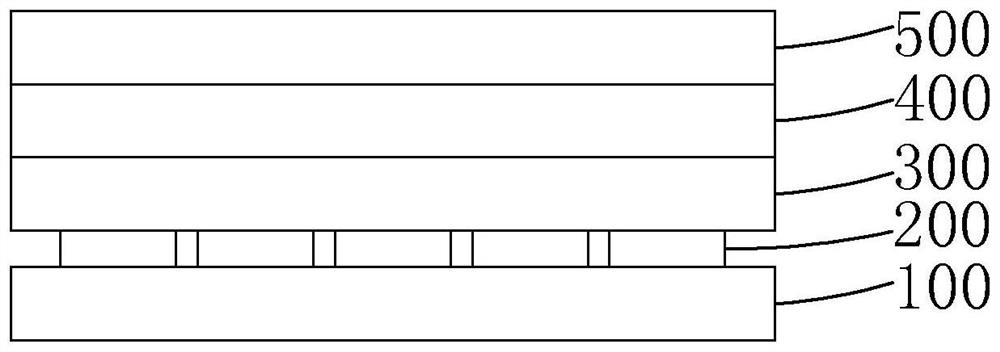

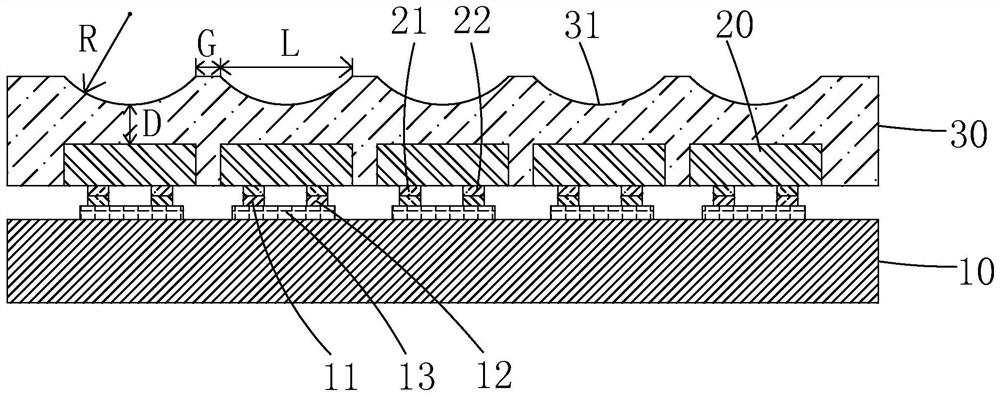

[0028] see image 3 , is a schematic diagram of the first embodiment of the surface light source backlight module of the present invention, including a Mini LED substrate 10, several Mini LED chips 20 arranged at intervals on the Mini LED substrate 10, and covering the several Mini LED chips 20 of the fluorescent film 30, the surface of the fluorescent film 30 away from the plurality of Mini LED chips 20 is provided with several microstructures 31 to improve the light mixing effect of the surface light source backlight module and improve the uniformity of brightness in the surface. Therefore, compared with the traditional backlight module, there is no need to arrange an optical film on the fluorescent film 30 to achieve the effect of uniform l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com