RFID electronic tag packaging device applied to assembly concrete member

A technology of electronic tags and packaging devices, which is applied to recording carriers used in machines, computer components, instruments, etc., can solve the electromagnetic interference of RFID electronic tags, cannot form a stable and reliable fixed structure, and cannot collect RFID electronic tag data stably and accurately and other issues to achieve the effect of reducing electromagnetic interference and reflection crosstalk, avoiding data loss, and improving physical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and embodiments.

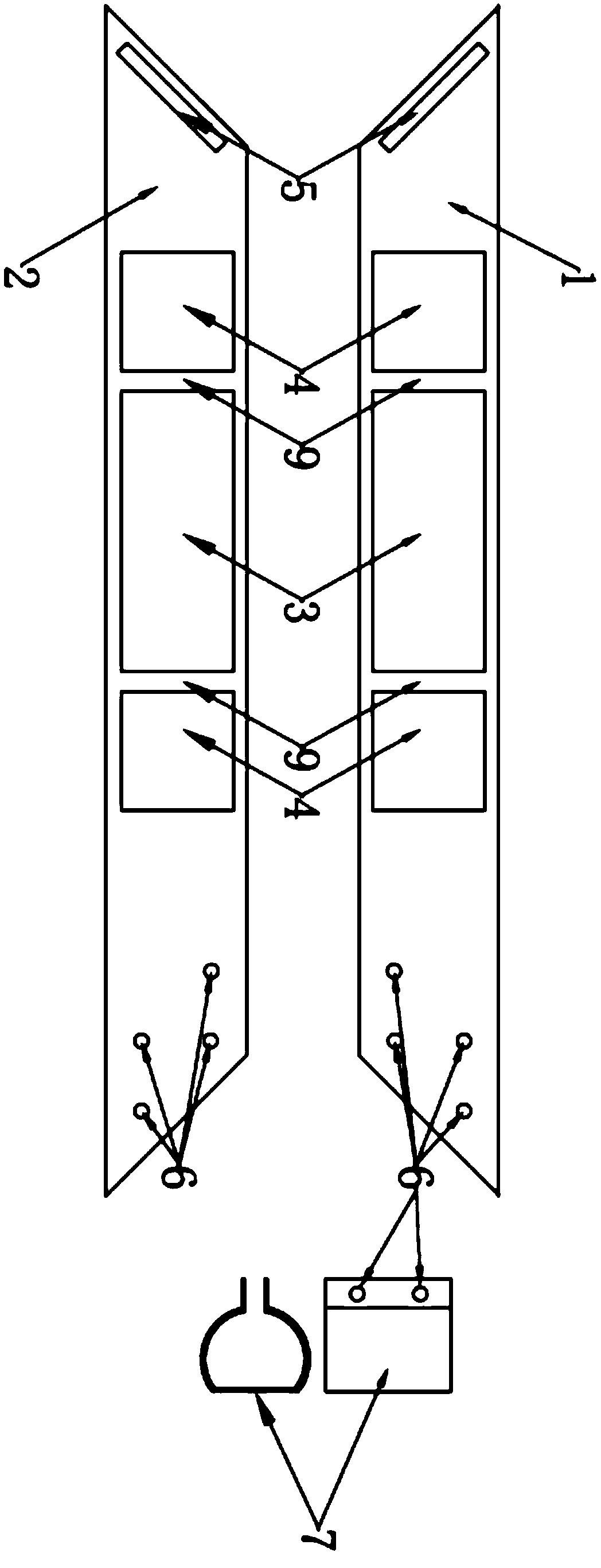

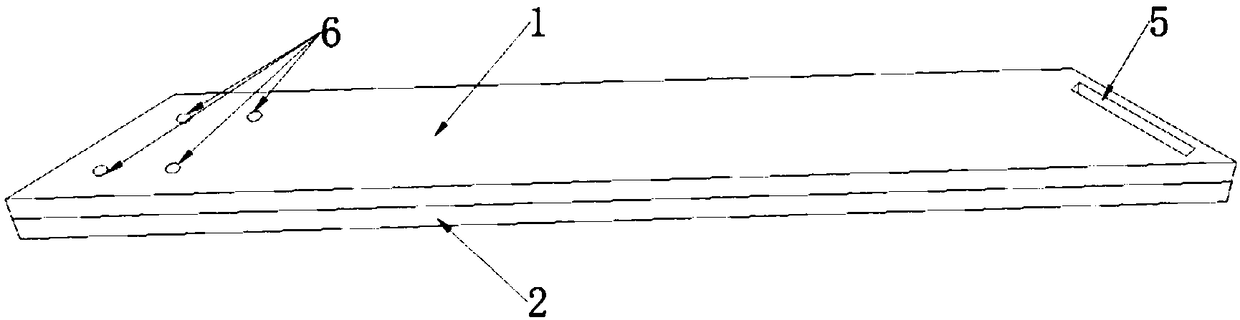

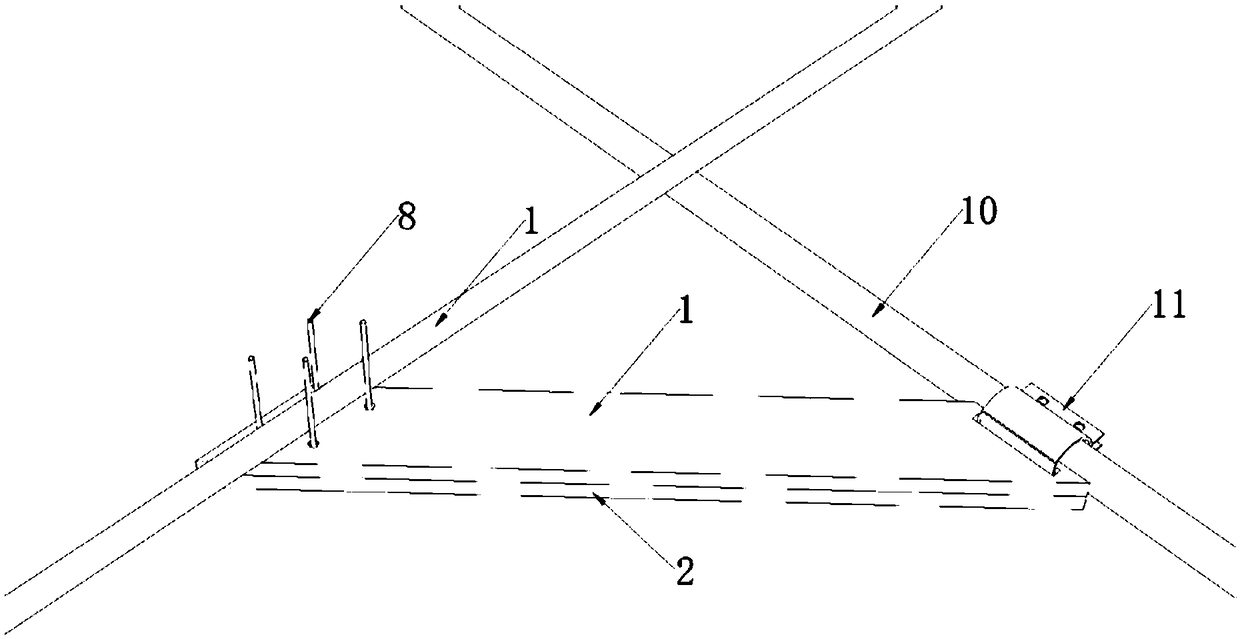

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention provides an RFID electronic tag packaging device applied to a fabricated concrete member, which includes: an RFID electronic tag packaging device and a fixed connection device. Among them, the RFID electronic label packaging device includes upper and lower substrates 1, 2. A label bin 3 is provided on the surface of the upper substrate 1, and a packaging bin 4 for filling solid glue to achieve sealing is provided on both sides of the label bin 3. The label bin 3 and A supporting structure 9 is arranged between the two packaging bins 4; the lower base plate 2 and the upper base plate 1 are mirror-symmetrical to each other; the two ends of the RFID electronic label packaging device are fixedly arranged in the existing prefabricated concrete member reinforcement cage through the fixed connection device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com