Adjustable solar silicon wafer storage equipment

A technology of solar silicon wafers and storage devices, applied in the direction of climate sustainability, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of inability to move up and down, single function, etc., achieve simple structure, reduce labor intensity, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

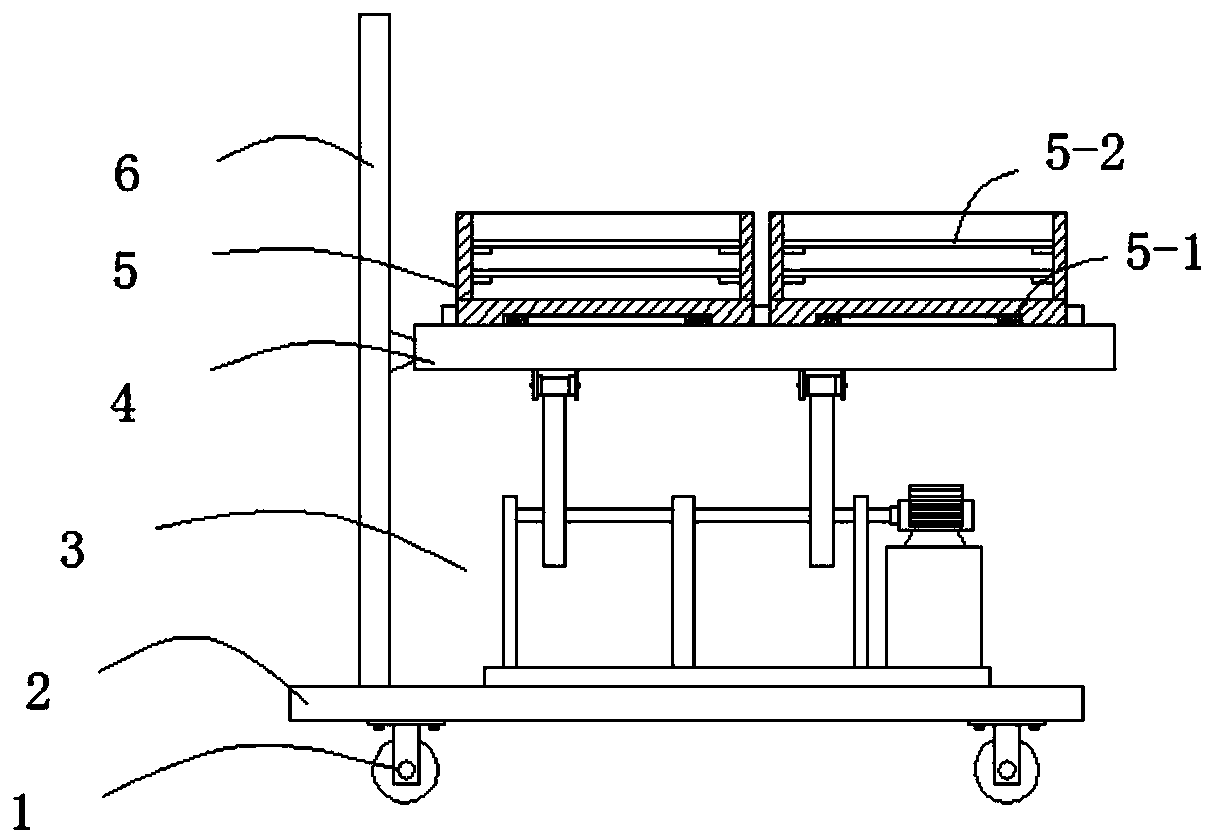

[0023] Such as Figures 1 to 2 As shown, this embodiment provides an adjustable solar silicon wafer storage device, which includes a bottom support plate 2, and is characterized in that a vertical guide plate 6 is provided on one side of the bottom support plate 2, and a vertical guide plate 6 is provided above the bottom support plate 2. A horizontal placement mechanism 4 that moves up and down along the vertical guide plate 6. The horizontal placement mechanism 4 is provided with a plurality of storage areas 4-1, and the storage area 4-1 is provided with a composite storage box 5 for loading solar silicon wafers. , the bottom support plate 2 is provided with a composite drive mechanism 3 composite storage box 5 that drives the horizontal placement mechanism 4 up and down.

[0024] The storage area 4-1 is provided with a positioning protruding ring 4-1.1, and the lower surface of the bottom of the composite storage box 5 is provided with a center groove 5-1 that cooperates wi...

Embodiment 2

[0027] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0028] A plurality of placement boards 5-2 are detachably arranged in the composite storage box 5 .

[0029] The horizontal placement mechanism 4 includes a horizontal plate 4-2, on which a guide block 4-4 cooperating with the vertical guide plate 6 is arranged.

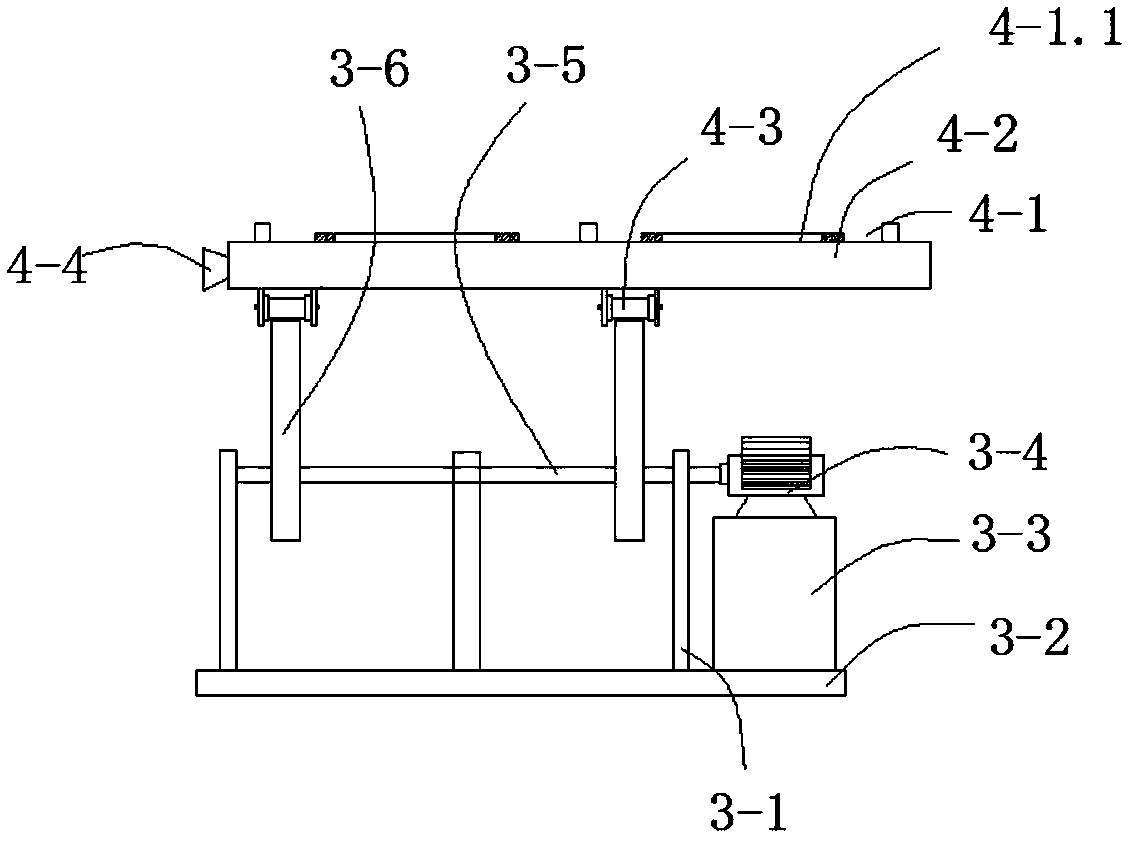

[0030] The compound driving mechanism 3 is a combined eccentric wheel lifting mechanism, and the combined eccentric wheel lifting mechanism includes a rotating shaft 3-5, a base plate 3-2 fixed on the bottom support plate 2, and a base plate 3-2 on the base plate 3-2. Three supporting plates 3-1 for supporting the rotating shaft 3-5 are arranged at equal intervals, and an eccentric wheel 3-6 and a horizontal plate 4 are arranged on the rotating shaft 3-5 between two adjacent supporting plates 3-1. A contact wheel 4-3 that cooperates with the eccentric wheel 3-6 is arranged below the -2.

[0031] One end of the rotating shaft 3...

Embodiment 3

[0033] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0034] The contact wheel 4-3 is a different-diameter wheel whose middle diameter is smaller than that of both ends, and the width of the middle small diameter part of the contact wheel 4-3 is 0.5-1 mm larger than the width of the eccentric wheel 3-6.

[0035] A plurality of mobile roller mechanisms 1 with brake mechanisms are arranged under the bottom support plate 2 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap